Straw wet anaerobic fermentation and aerobic fermentation combined treatment device and method

An anaerobic fermentation and aerobic fermentation technology, applied in the direction of joint biological treatment, bioreactor/fermentation tank combination, fertilization device, etc., can solve the difficulty of cellulose decomposition, the difficulty of resource utilization, and the inability to process biogas slurry, etc. problems, achieve low operating costs, reduce investment and operating costs, and achieve the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

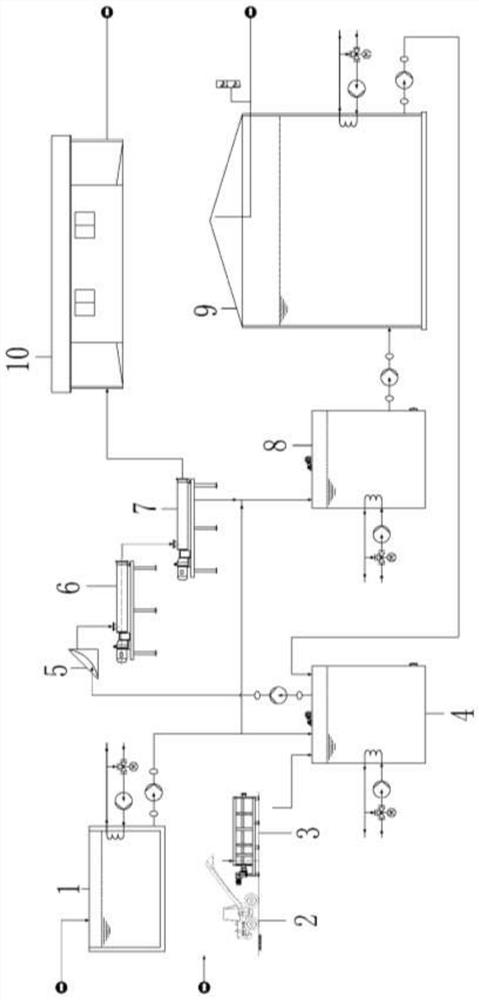

[0042] (1) Firstly, the straw (the straw storage tank is set in the field) is sent to the straw grinder 3 through the straw loading tool 2 for shredding treatment, and then sent to the hydrolysis tank 4 through the belt.

[0043] (2) After the off-site biogas slurry is transported to the biogas slurry storage tank 1, it is pumped into the hydrolysis tank 4 for hydrolysis and acidification treatment.

[0044] (3) The material after hydrolysis and acidification is subjected to the first solid-liquid separation by Type I solid-liquid separator 5 .

[0045](4) Then enter the pipeline pulping machine 6 to prepare slurry, the slurry after pulping enters the second solid-liquid separation, and the cellulose that is difficult to anaerobic fermentation is separated and sent to the organic fertilizer workshop, and the remaining slurry (solid content) 12.5%) is pumped to the temporary storage tank, and then pumped into the anaerobic fermentation tank.

[0046] (5) The slurry is subjecte...

Embodiment 2

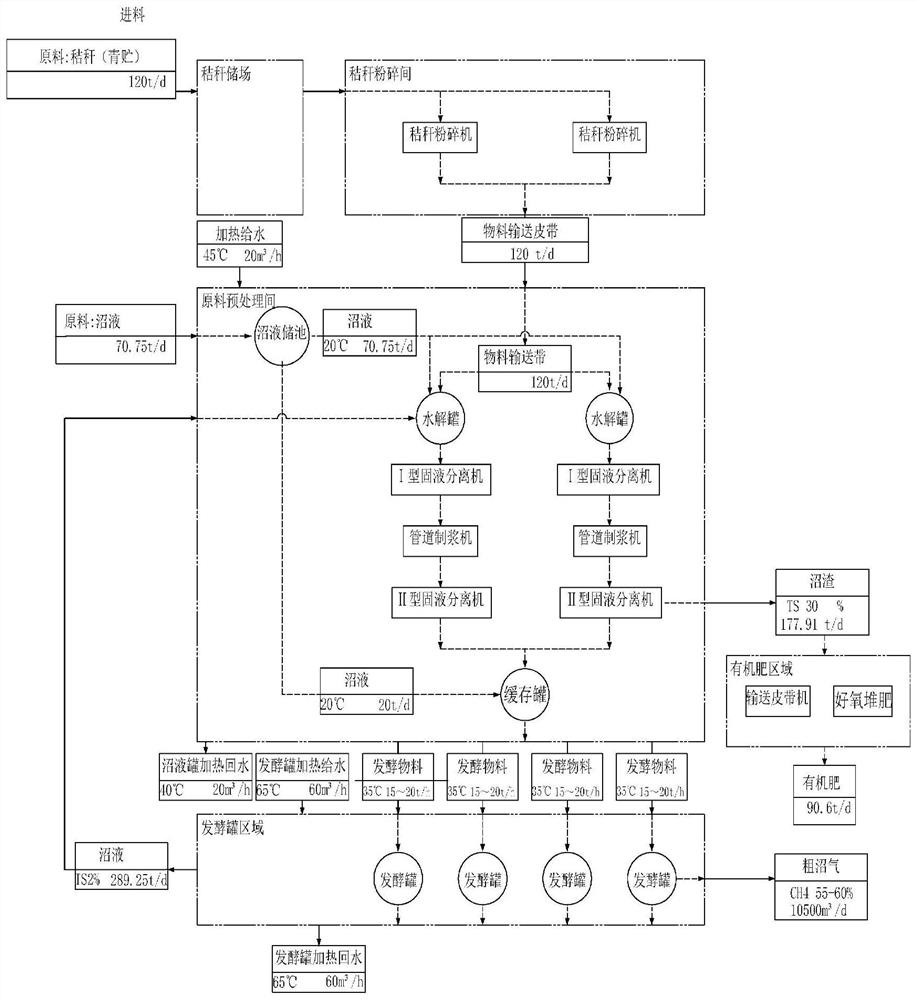

[0050] Material balance using silage corn stalks (TS45%) and biogas slurry (TS5%) as raw material project case introduction.

[0051] (1) Raw materials: The daily processing capacity of silage corn stalks (TS45%) is 120 tons, the daily consumption of biogas slurry (TS5%) is 360 tons, and the total amount of materials per day is 480 tons. The biogas slurry storage tank 1 is kept warm and the temperature is about 20°C.

[0052] (2) The hydraulic retention time of the hydrolysis tank is 24 hours, and the TS is 15%.

[0053] (3) After the second solid-liquid separation of the material after hydrolysis and acidification, the cellulose part used for composting is about 177.91 tons per day (including the solid-liquid separation part after anaerobic fermentation), TS30%, and the part used for anaerobic fermentation is about 177.91 tons per day. 360 tons, TS10%.

[0054] (4) Anaerobic fermentation produces 10,500 cubic meters of biogas and about 289.25 tons of biogas slurry per day (...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap