Lining device for epitaxial reaction chamber and epitaxial reaction chamber

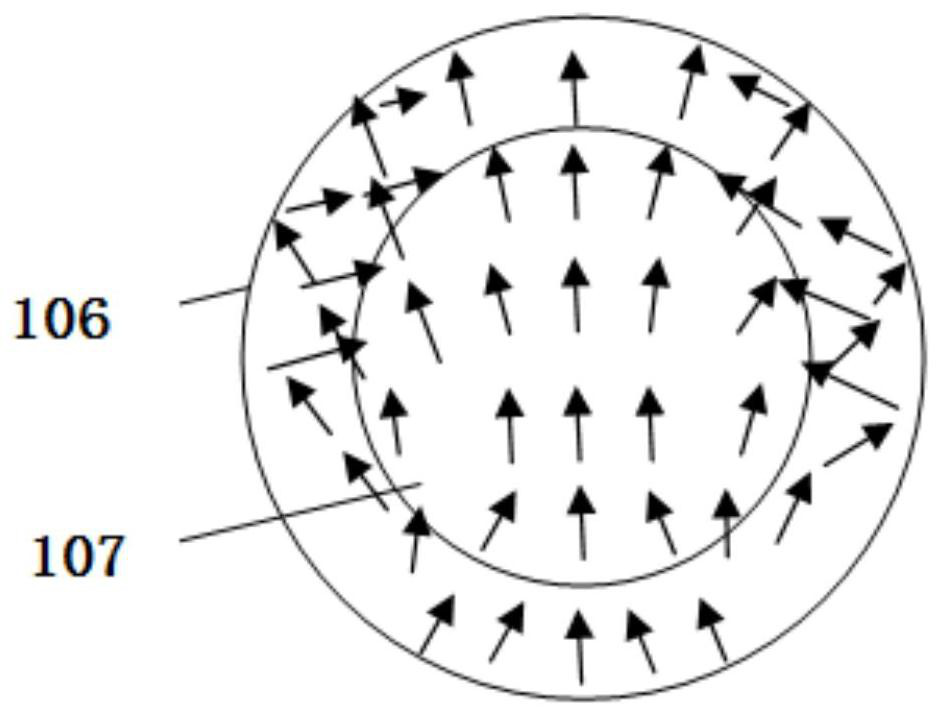

A reaction chamber and epitaxy technology, applied in the direction of chemical reactive gas, crystal growth, coating, etc., can solve the problems of difficult adjustment, uneven air flow field, affecting the surface process of silicon wafer 107, etc., to achieve uniform distribution, improve Process effect, performance index uniform and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

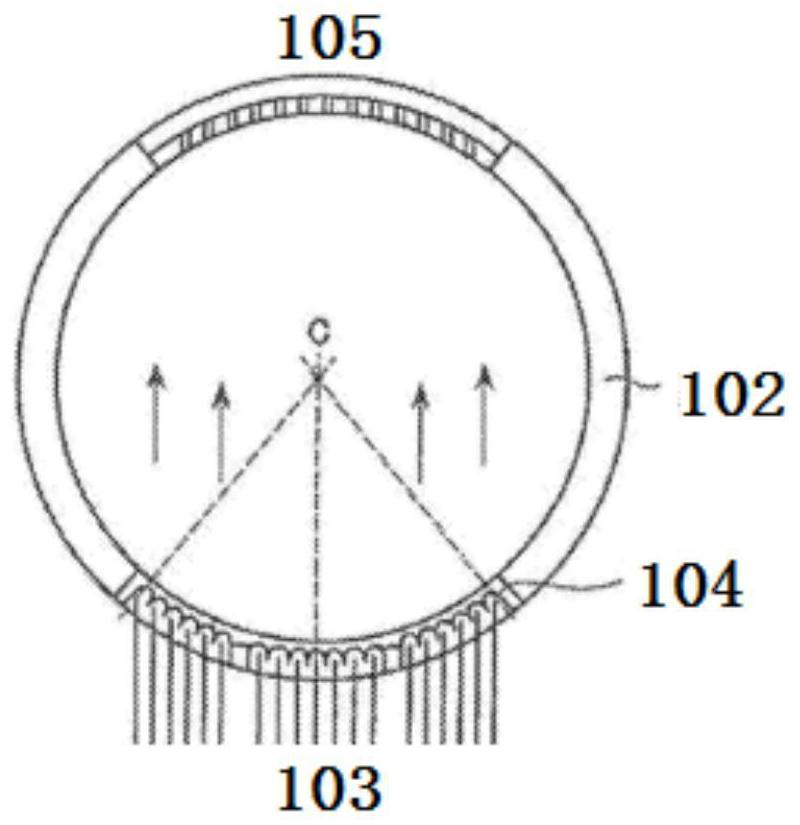

[0045] Figure 4 A schematic diagram of the overall structure of a lining device for an epitaxial reaction chamber according to an embodiment of the present invention is shown.

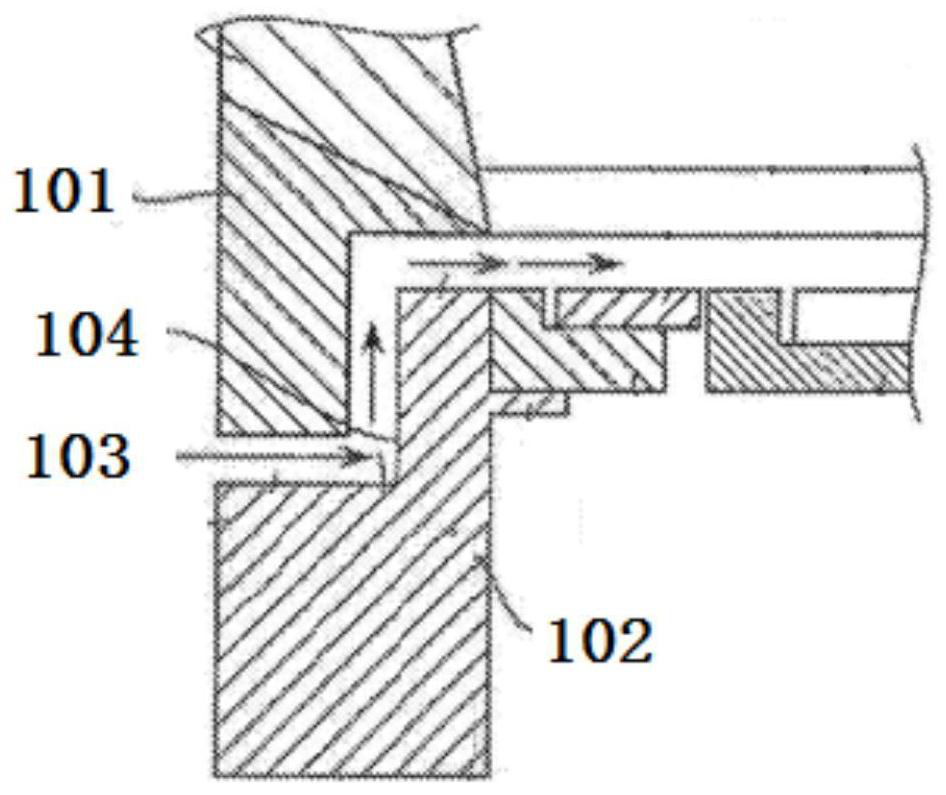

[0046] Such as Figure 4 As shown, a lining device for an epitaxial reaction chamber includes: an upper lining ring 1 and a lower lining ring 2, the upper lining ring 1 is placed above the lower lining ring 2 and coaxially arranged with the lower lining ring 2;

[0047] combine Figure 5 to Figure 8 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com