Uniform negative-pressure drum type web former of melt-blowing equipment and melt-blown fabric production process

A web-forming machine and drum-type technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve problems such as uneven molding, creases, and fabric wrinkles, so as to improve uniformity and reduce the probability of wrinkles and creases Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

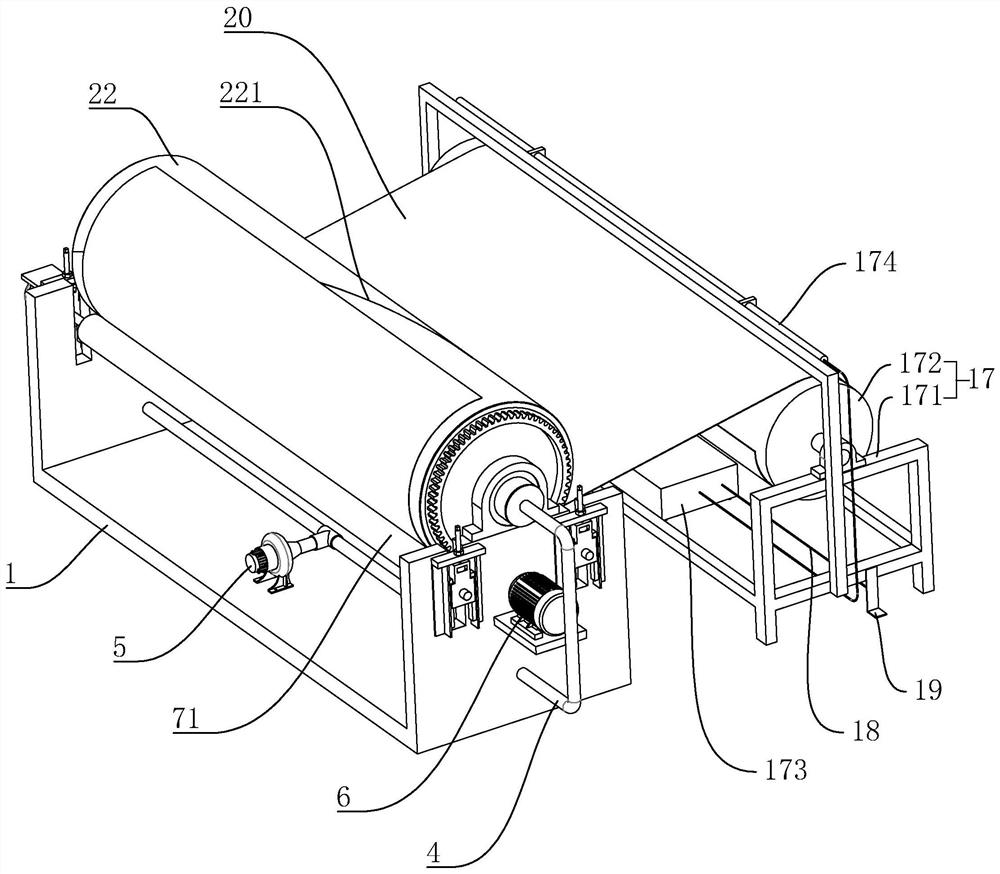

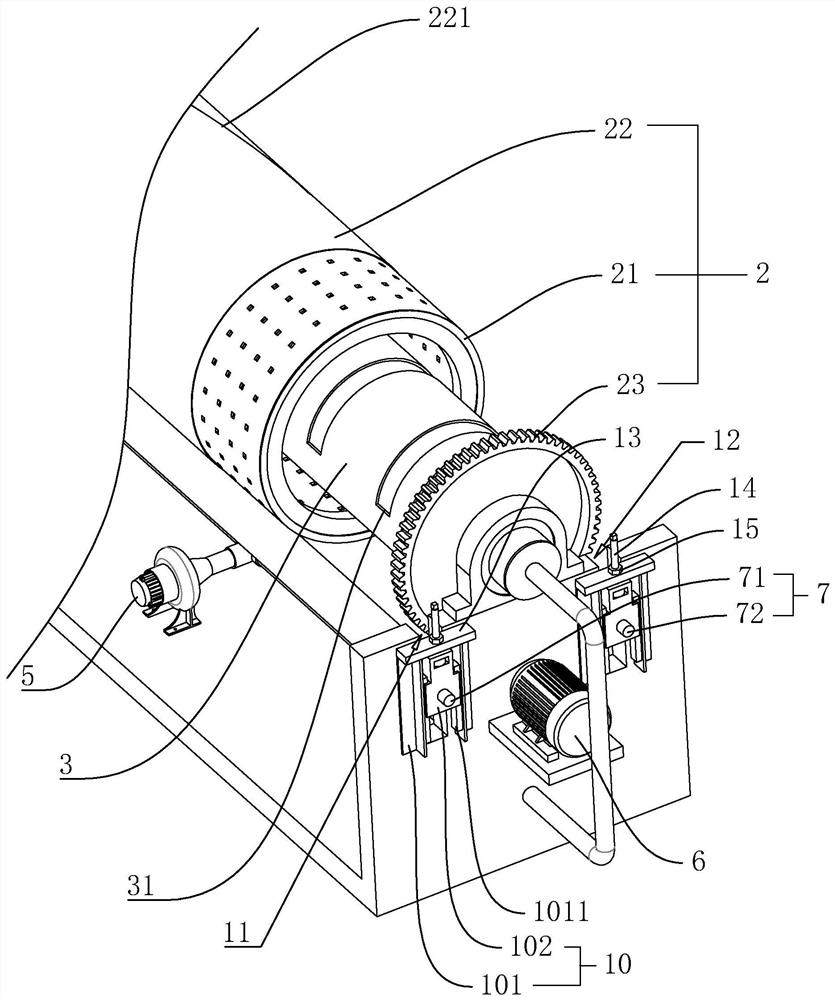

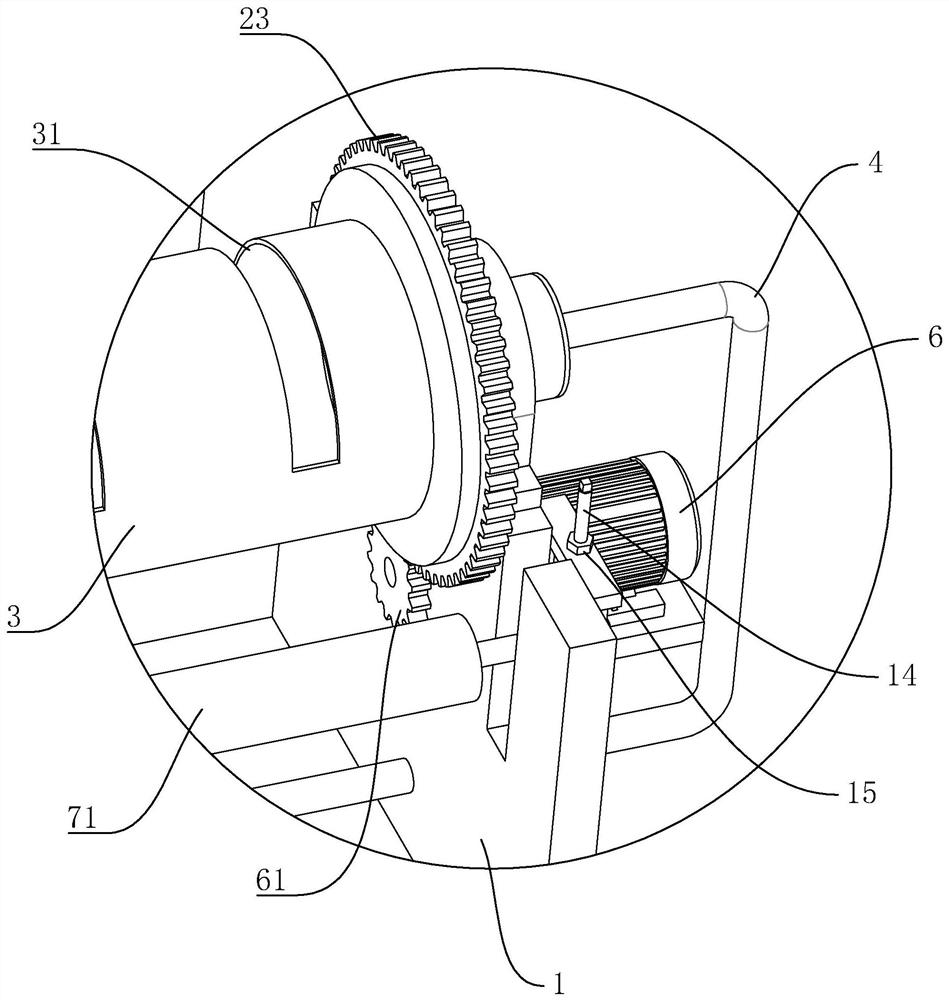

[0045] Embodiment: a kind of melt blown equipment uniform negative pressure drum type web forming machine, such as figure 1 As shown, it includes a frame 1 and a receiving drum 2 arranged on the frame 1. The receiving drum 2 includes an inner cylinder 21 and a filter screen 22 welded to the outer layer of the inner tube 21. The filter screen 22 is made of stainless steel with good cooling effect. The opening rate of the mesh 22 is 40%-50%; the filter mesh 22 is welded with a diagonal weld 221, and the diagonal weld 221 is formed by spiral welding along the outer wall of the inner cylinder 21, and the filter mesh 22 is welded and fixed by adopting a spiral oblique welding method, Can increase the weld length of the filter screen 22 welding, compared with the butt welding, the use of spiral oblique welding can ensure that the filter screen 22 is welded firmly, and at the same time reduce the width of the edge overlap of the welding site as much as possible, thereby improving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com