A small wind power generation device and method adaptive to wind direction and wind speed

A wind power generation and self-adaptive technology, applied in wind power generation, piezoelectric effect/electrostrictive or magnetostrictive motors, wind turbines, etc. Power generation efficiency, the effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

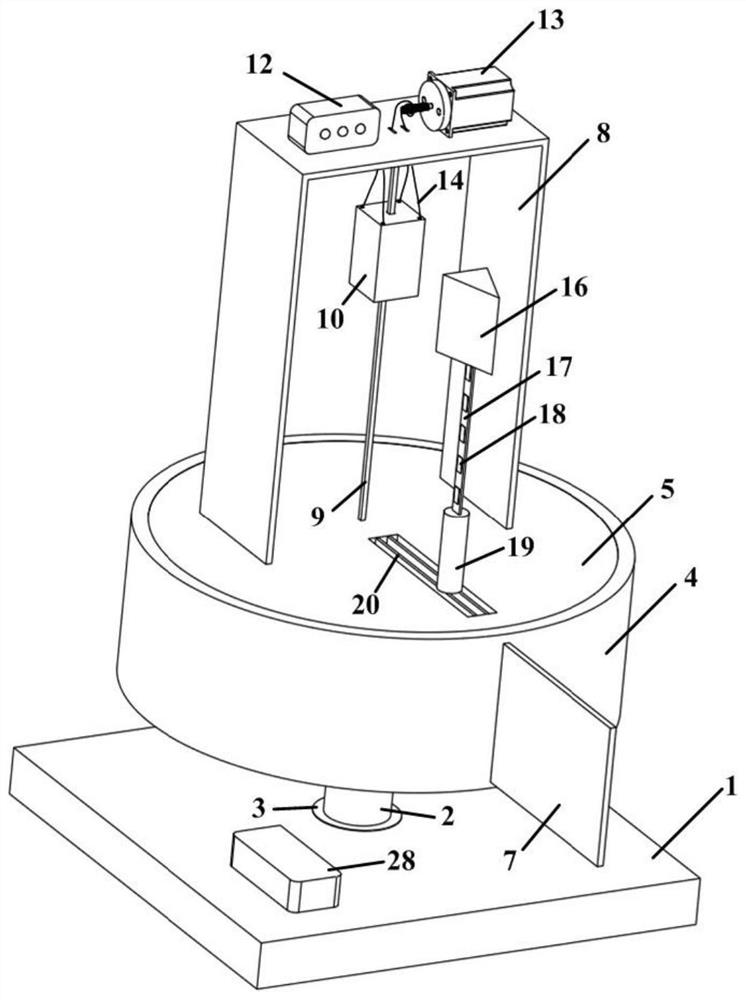

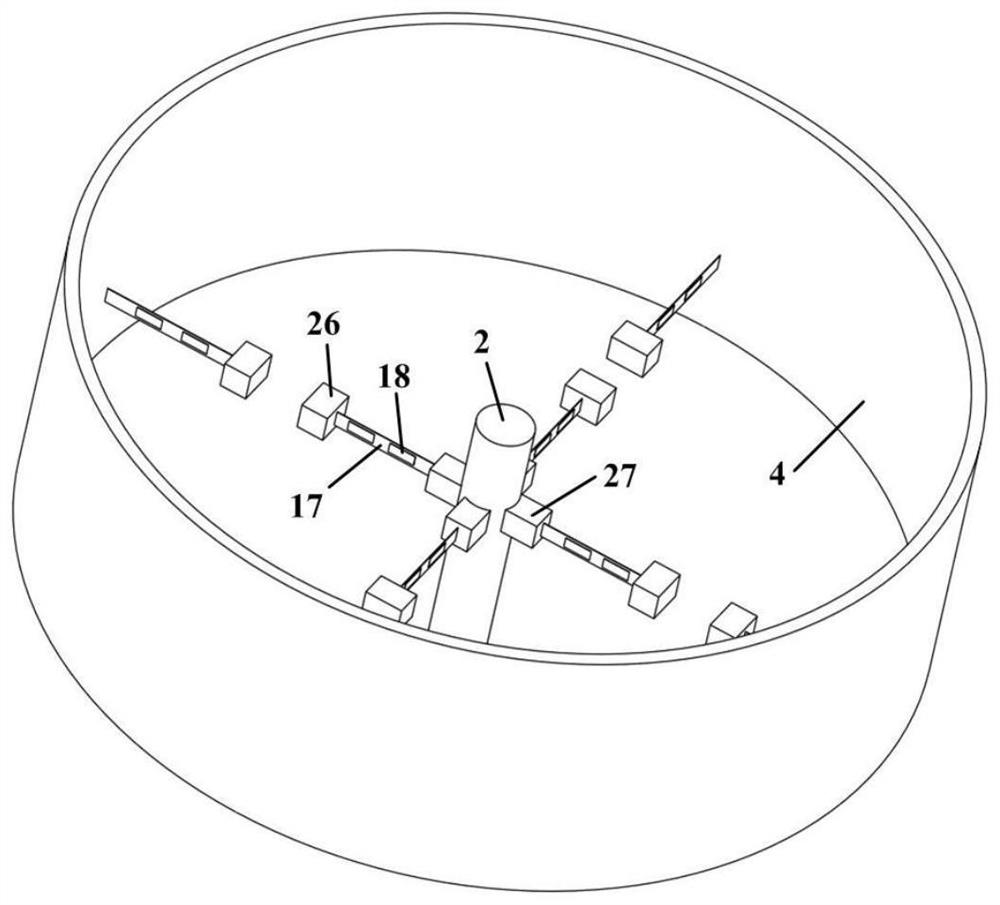

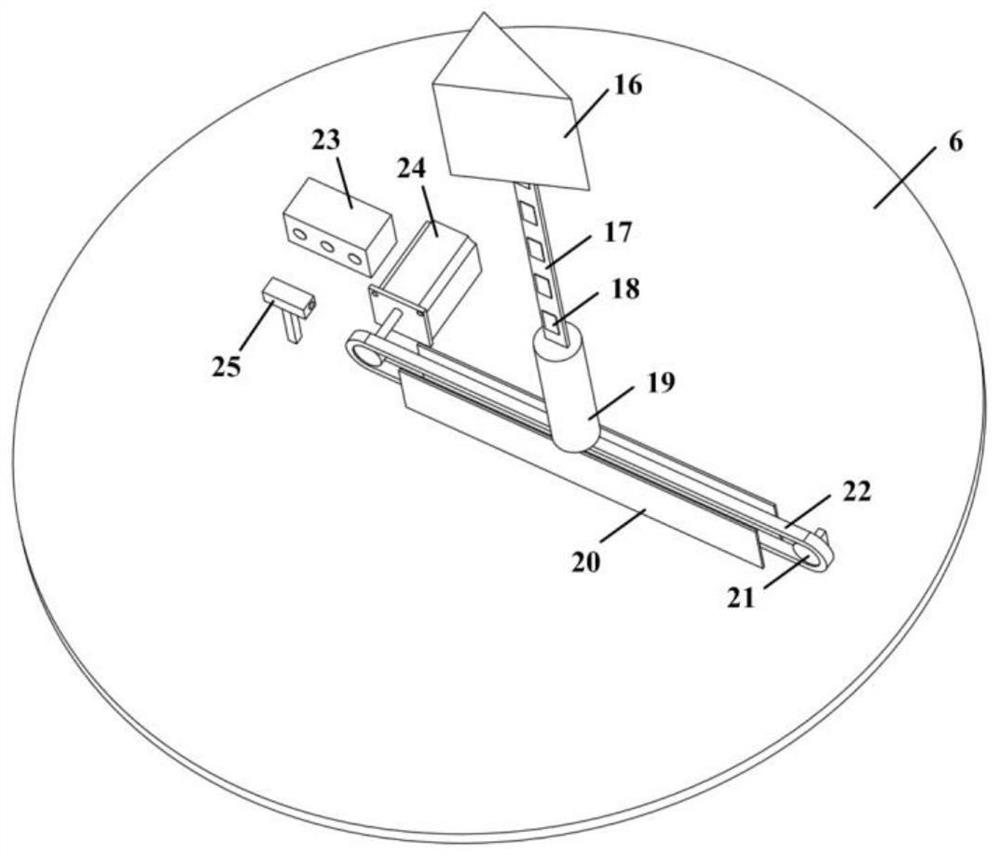

[0034] The device of the present invention adopts modular installation. Firstly, the fixed base 1 is fixedly installed in the wind field, and the rotating bearing 3 is installed in the blind hole in the middle of the fixed base 1. The lower end of the rotating support rod 2 is inserted into the rotating bearing 3, and the The upper end is welded and fixed to the internal partition 6, and the circumferential wall of the internal partition 6 is welded and fixed to the inner wall of the rotating shell 4. The four pairs of cantilever beam power generation components located below the internal partition 6 are respectively installed on the inner wall of the rotating shell 4 and the rotating strut. 2 In the fixed block 27 evenly arranged in the circumferential direction, the installation of the wind speed adaptive adjustment module and the rotation-induced swing power generation module has been completed so far; 5 is welded on the top of the rotating shell 4; finally, the vertical pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com