Liquid output pump suitable for operating in low-temperature environment and vehicle-mounted liquefied natural gas (LNG) bottle

A low-temperature environment, liquid pump technology, applied in the direction of pumps, motor vehicles, piston pumps, etc., can solve the problem that the liquid pump is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

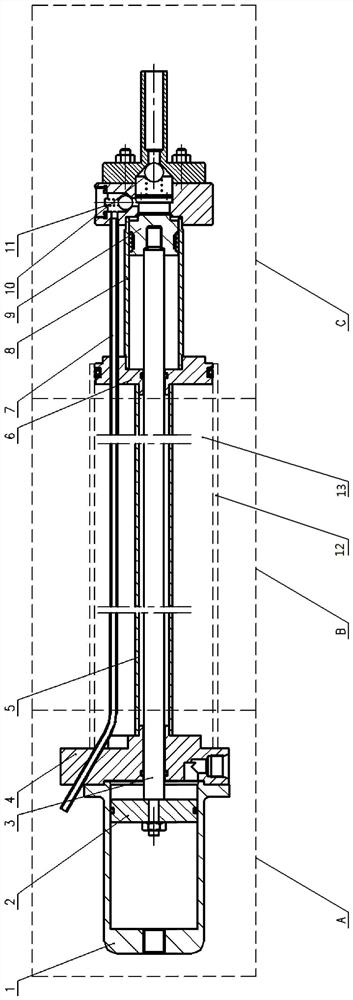

[0034] This embodiment is a specific liquid outlet pump, such as figure 1 As shown, the liquid outlet pump is mainly composed of hydraulic cylinder 1, cylinder liner 5, installation sleeve 12, piston cylinder 8, power piston 2, piston rod 3, working piston 9, liquid inlet check valve 10, liquid outlet check valve 11 and liquid outlet pipe 7 are assembled;

[0035] When working, the hydraulic pressure of the power end A drives the power piston 2 to reciprocate in the hydraulic cylinder 1, and the power piston 2 drives the piston rod 3 to drive the working piston 9 to work;

[0036] When the working piston 9 moves towards the hydraulic cylinder 1, a negative pressure is formed in the piston cylinder 8 at the working end C, and the negative pressure makes the liquid outlet check valve 10 close, and at the same time makes the liquid inlet check valve 11 open to suck LNG into the piston cylinder 8 ;

[0037] When the working piston 9 moves away from the direction of the hydraulic...

Embodiment 2

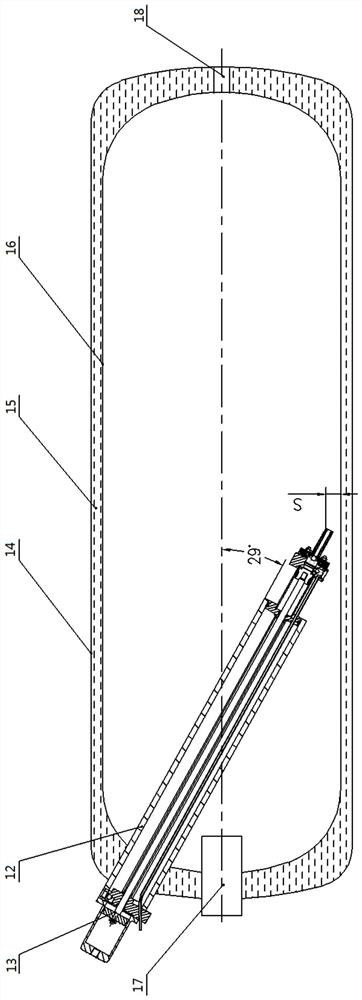

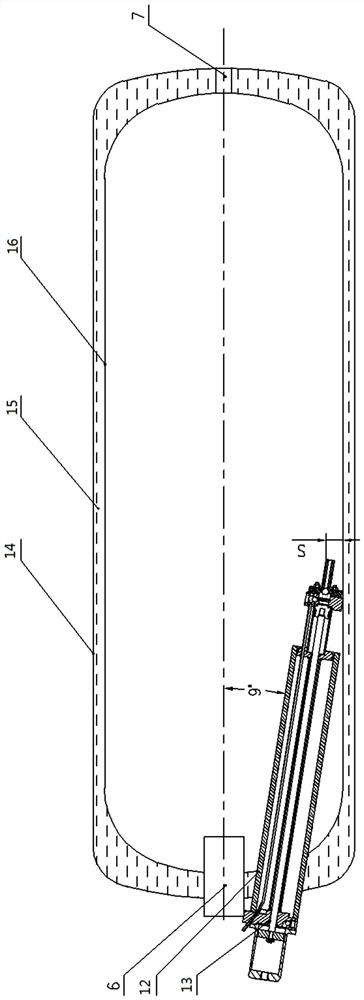

[0046] This embodiment is a gas cylinder equipped with a liquid outlet pump 13 of the present invention. refer to figure 2 As shown, the gas cylinder body includes a gas cylinder body 14 and a gas cylinder liner 16, a vacuum interlayer 15 is arranged between the two, and the gas cylinder body 14 and the gas cylinder liner 16 are fixed by the gas cylinder distributor 17 and extended. The 18 ends of the sliding support slide to prevent the deformation of the cylinder inner liner 4 to produce stress when the temperature changes.

[0047] The installation sleeve 12 is welded to its gas cylinder body 14 and the gas cylinder liner 16 respectively, and is formed at 29° to the horizontal axis of the gas cylinder; the liquid outlet pump 1 penetrates into the installation sleeve, and the first flange on the liquid outlet pump 13 is connected to the installation sleeve. The end faces of the sleeve pipe 12 are connected with bolts. When installing, ensure the minimum distance S=80mm be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com