Semi-intelligent differential lock closed-loop control system and method based on differential lock controller

A closed-loop control, differential lock technology, applied in the control device, differential transmission, transmission control, etc., can solve the problem of unable to control the differential lock to automatically exit from work, the differential lock to work for a long time, and the axle to hit teeth, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

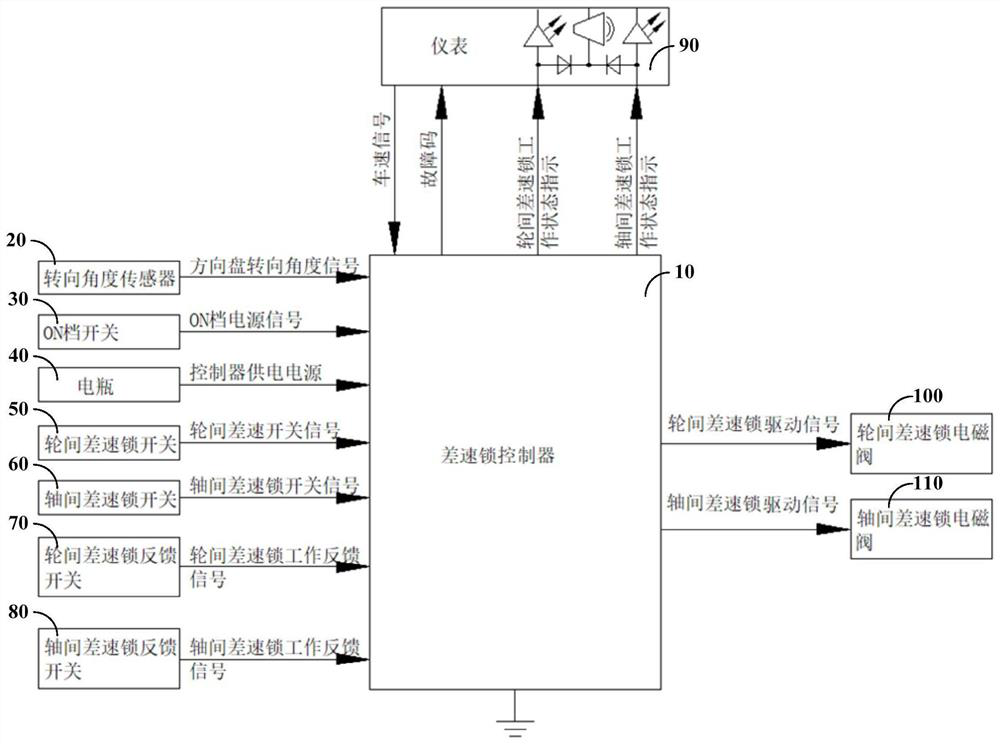

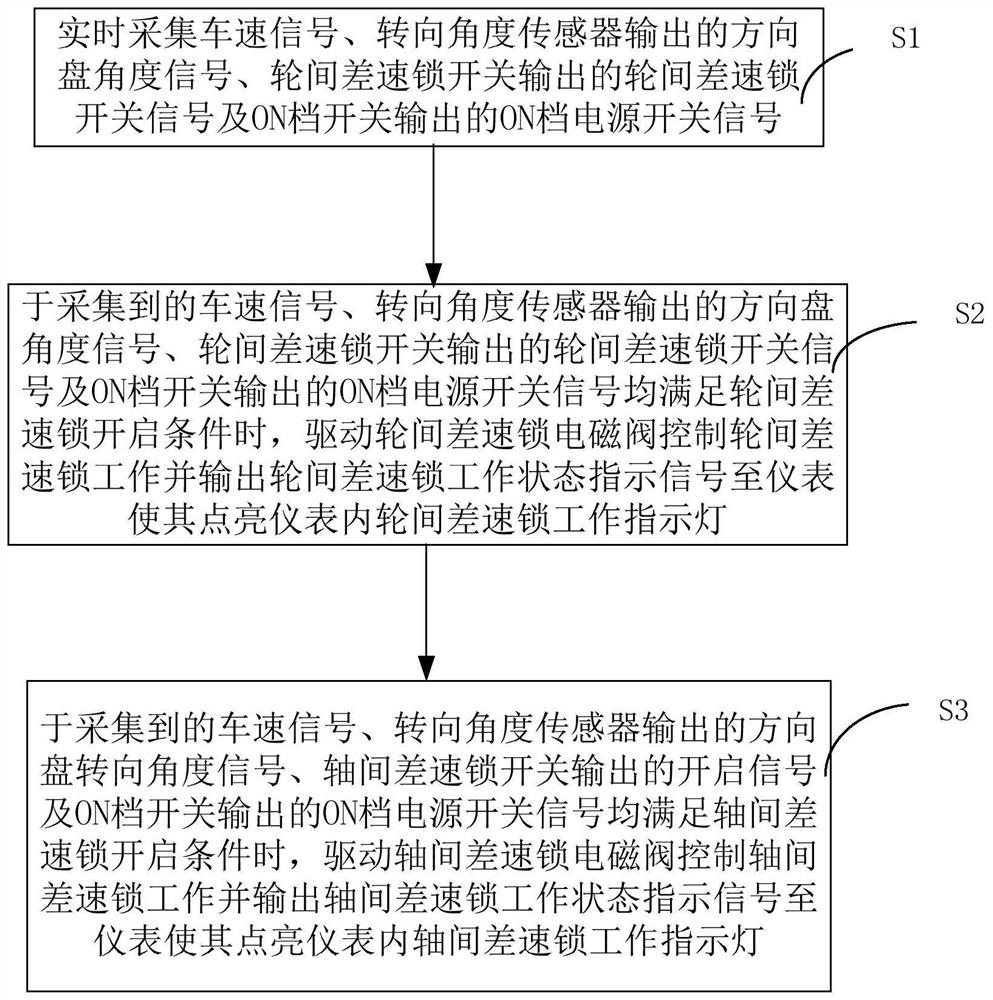

[0089] In this embodiment, the inter-wheel differential lock control function logic is as follows:

[0090] 1.1. The inter-wheel differential lock switch adopts a self-locking switch. When the switch is turned on, a low potential signal is input to the differential lock controller; when the switch is turned off, a high potential signal is input to the differential lock controller.

[0091] 1.2. Time limit: When the vehicle speed is <1km / h, the steering angle is <10°, and the signal of the ON switch is valid, press the inter-wheel differential lock switch, and the differential lock controller collects the above signals. When the inter-wheel differential is satisfied When the lock condition occurs, the solenoid valve of the drive wheel differential lock controls the wheel differential lock to work and lights up the working indicator light of the wheel differential lock in the instrument; after working continuously for 5 minutes, the differential lock controller automatically stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com