Primer-free aluminum plating process for motorcycle LED reflector

A reflector and primer-free technology, which is applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve problems such as complex manufacturing process, achieve the effects of improving heat dissipation, reducing production costs, and simplifying the photocuring process of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

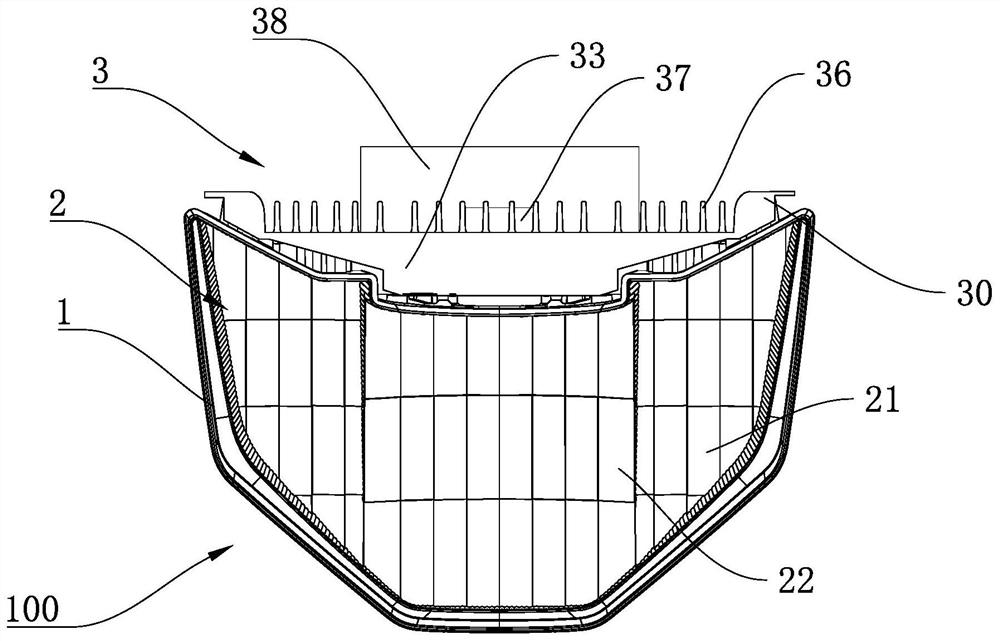

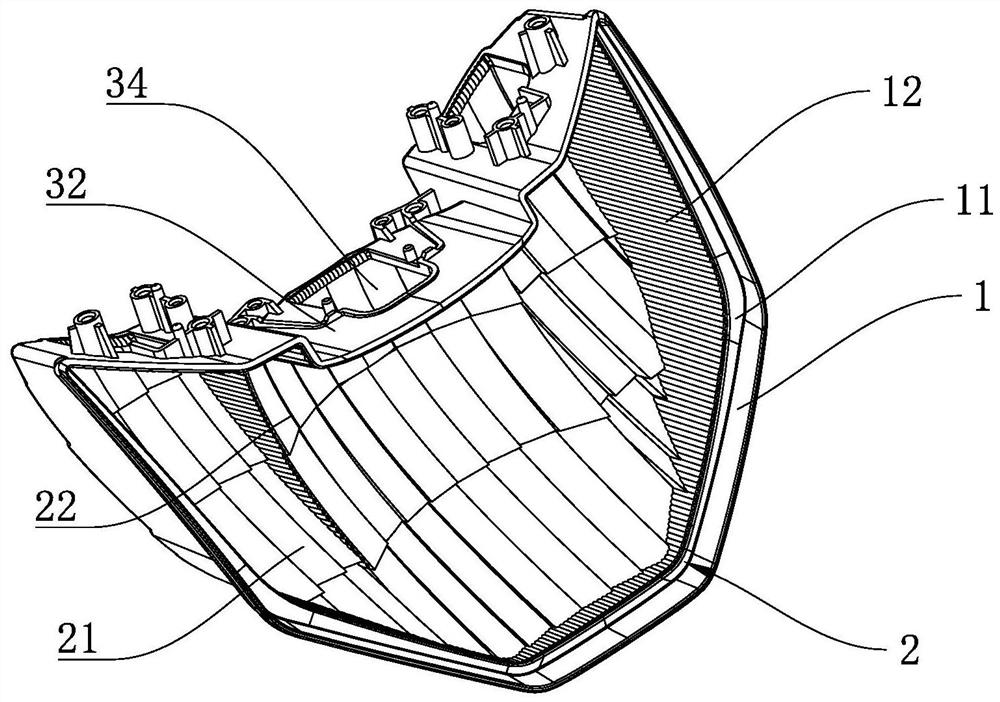

[0031] This embodiment provides a process for aluminizing a motorcycle LED reflector without primer coating, which includes the following steps:

[0032] Step 1: Melt and stir the reflector raw materials until they are evenly mixed;

[0033] Step 2: Inject the uniformly mixed molten raw materials into the molding mold with an injection molding machine, open the mold and eject it after maintaining the pressure, polish it with a milling machine after natural cooling, and then immerse it in the cyclohexanone solution for 5 minutes to obtain a semi-finished product;

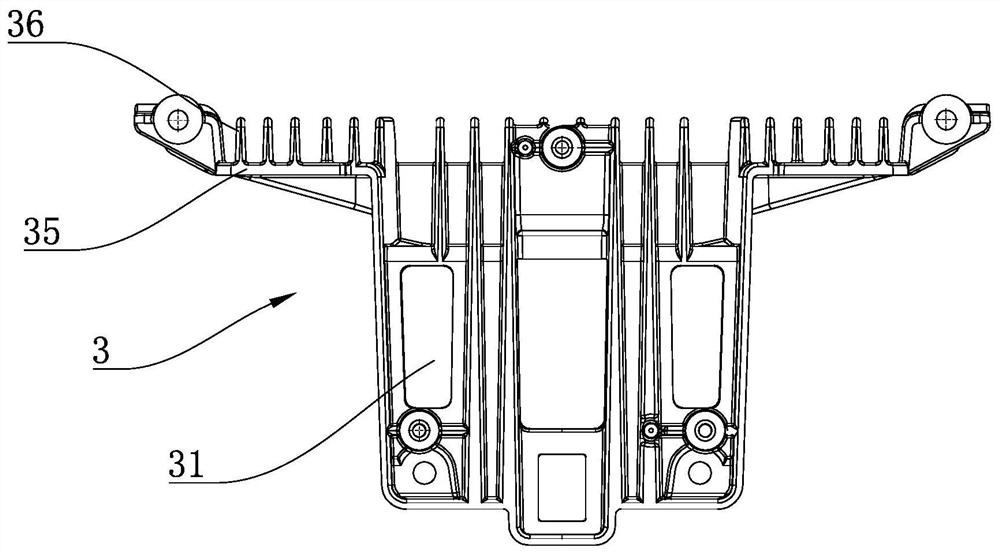

[0034] Step 3: Assembling the heat dissipation component 3 on the semi-finished product obtained in Step 2 to obtain the finished reflector 100 .

[0035] Wherein, the raw material of the mirror includes 50 parts by mass of PVC resin, 50 parts of PEEK resin, 10 parts of plasticizer, 30 parts of zinc oxide, 15 parts of compatibilizer, 1 part of antioxidant, 10 parts of triethylene glycol monobutyl ether, 2 parts of 1...

Embodiment 2

[0046] This embodiment provides a process for aluminizing a motorcycle LED reflector without primer coating, which includes the following steps:

[0047] Step 1: Melt and stir the reflector raw materials until they are evenly mixed;

[0048] Step 2: Inject the uniformly mixed molten raw material into the molding mold with an injection molding machine, open the mold and eject it after maintaining the pressure, polish it with a milling machine after natural cooling, and then immerse it in the cyclohexanone solution for 8 minutes to obtain a semi-finished product;

[0049] Step 3: Assembling the heat dissipation component 3 on the semi-finished product obtained in Step 2 to obtain the finished reflector 100 .

[0050] Wherein, the raw material of the mirror includes 70 parts by mass of PVC resin, 30 parts of PEEK resin, 5 parts of plasticizer, 20 parts of zinc oxide, 10 parts of compatibilizer, 0.1 part of antioxidant, 5 parts of triethylene glycol monobutyl ether, 1 part of 1,4...

Embodiment 3

[0053] This embodiment provides a process for aluminizing a motorcycle LED reflector without primer coating, which includes the following steps:

[0054] Step 1: Melt and stir the reflector raw materials until they are evenly mixed;

[0055] Step 2: Inject the uniformly mixed molten raw materials into the molding mold with an injection molding machine, open the mold and eject it after maintaining the pressure, polish it with a milling machine after natural cooling, and then immerse it in the cyclohexanone solution for 10 minutes to obtain a semi-finished product;

[0056] Step 3: Assembling the heat dissipation component 3 on the semi-finished product obtained in Step 2 to obtain the finished reflector 100 .

[0057] Wherein, the raw material of the mirror includes 60 parts by mass of PVC resin, 40 parts of PEEK resin, 8 parts of plasticizer, 15 parts of zinc oxide, 12 parts of compatibilizer, 0.5 part of antioxidant, 8 parts of triethylene glycol monobutyl ether, 1.5 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com