HiB steel decarburization and nitridation annealing roll sample preparation method and nitrogen content detection method

A decarburization and nitriding technology, which is used in the preparation, sampling, and measuring devices of test samples, and can solve problems such as affecting the accuracy of test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]The sample preparation method of HiB steel decarburization and nitriding annealing coil comprises the following steps:

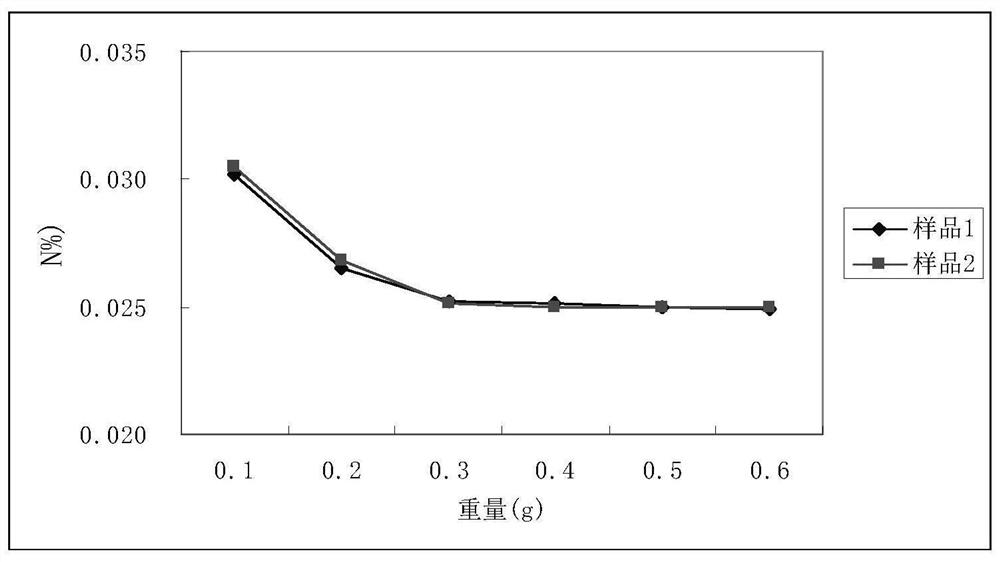

[0049] Use scissors to cut out a sample of about 24mm×10mm on the template, and control the weight at about 0.35g±0.02g.

[0050] The sample was crimped into a ball with needle nose pliers.

[0051] Clean the sample with ultrasound and ethanol for 3 minutes, take it out, and dry it with a hair dryer for inspection.

[0052] Compared with the prior art, the sample preparation method of this embodiment will not jam the sample, completely retain the surface nitriding layer, and there is no adhesion of foreign matter such as absorbent cotton. And the sample preparation speed is fast, the whole process only takes about 4 minutes.

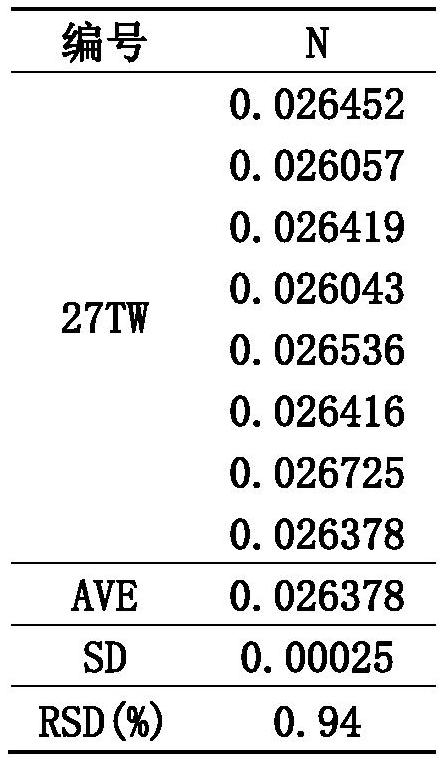

[0053] The decarburization and nitriding annealing coil of HiB steel No. 27TW was sampled and treated by the above method, and 8 samples were prepared, and the nitrogen content of the prepared samples was detected by the implem...

Embodiment 2

[0057] Adopt the sample preparation method of embodiment 1 to carry out sample preparation to the HiB steel decarburization nitriding annealing coil that number is 0003TC, 0003TD, 27WD, 27TD-1, 27TD-2, adopt thin sample punch sample preparation method in the prior art simultaneously Samples were specifically prepared by punching pellets with a MLF-BLF punch, and the samples were also cleaned in the same manner as in Example 1. The specific meaning of each sample number is as follows: the number represents the roll number; the first letter T represents the head, W represents the tail; the second letter D represents the transmission side, C represents the middle part, and W represents the working side.

[0058] The nitrogen content of the samples prepared in the above two ways was tested using the implementation standard GB / T20124-2006.

[0059] The comparison data are shown in Table 2. The comparison deviation between this method and the sample preparation method of flushing pe...

Embodiment 3

[0065] In this embodiment, the decarburization and nitriding annealing coil of HiB steel numbered 20TM-2 is sample prepared, and the sample preparation steps are the same as in embodiment 1 except for the cleaning step of the crimped sample. In this embodiment, different methods are used to clean the curled samples, and the influence of the cleaning methods on the detection results is investigated.

[0066] 1. Experimental design

[0067] 1.1 Use hydrochloric acid, sodium bicarbonate, ethanol + ultrasonic three cleaning agents (methods) to clean the same steel coil sample, and then repeatedly detect the nitrogen element on the oxygen and nitrogen analyzer. The data are as follows:

[0068] 1.1.1 10% dilute hydrochloric acid cleaning

[0069] The sample was soaked in 10% dilute hydrochloric acid for 3 minutes. The reaction was violent during soaking. After soaking, the surface of the sample changed significantly.

[0070] Table 3 Precision test w / % after soaking in 10% dilute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roll diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com