Method for calculating ignition temperature of mixed pulverized coal airflow after blending combustion of two single coals

A technology of ignition temperature and coal type, which is applied in the field of calculation of ignition temperature of mixed coal pulverized coal airflow after blending of two single types of coal, can solve the problem of complex ignition performance of blended coal, unsatisfactory blending of coal, lack of quantitative research, etc. problems, to achieve the effect of a wide range of coal types, simple and fast calculation methods, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

[0031] Specific implementation case 1, typical lignite and anthracite blended coal pulverized coal gas flow ignition temperature IT, ℃:

[0032] Step 1: Provide the ignition temperature IT1 (°C) of the pulverized coal flow of coal type 1 and the ignition temperature IT2 (°C) of the pulverized coal flow of coal type 2, the blending ratio R1 (%) of coal type 1 and the blending ratio of coal type 2 Combustion ratio R2 (%), wherein R1+R2=100%, wherein coal type 1 is the coal type with excellent ignition performance, that is, the ignition temperature of the pulverized coal flow of coal type 1 is lower than the ignition temperature of the pulverized coal flow of coal type 2;

[0033] Lignite IT1=450°C, anthracite IT2=830°C;

[0034] Lignite blending ratio R1 = 5%, anthracite blending ratio R2 = 95%,

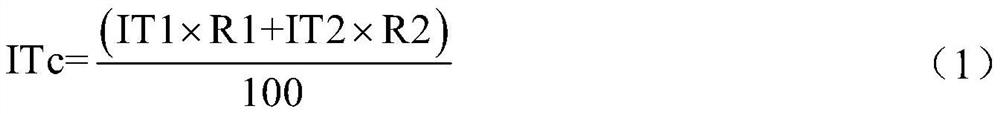

[0035] Step 2: Calculate the weighted average pulverized coal airflow ignition temperature ITc (in °C) of the mixed coal after coal type 1 and coal type 2 are mixed. For the specific ...

specific Embodiment example 2

[0054] Specific implementation case 2, typical bituminous coal and anthracite blended coal pulverized coal flow ignition temperature IT, ℃:

[0055] Step 1: Provide the ignition temperature IT1 (°C) of the pulverized coal flow of coal type 1 and the ignition temperature IT2 (°C) of the pulverized coal flow of coal type 2, the blending ratio R1 (%) of coal type 1 and the blending ratio of coal type 2 Combustion ratio R2 (%), wherein R1+R2=100%, wherein coal type 1 is the coal type with excellent ignition performance, that is, the ignition temperature of the pulverized coal flow of coal type 1 is lower than the ignition temperature of the pulverized coal flow of coal type 2;

[0056] Lignite IT1=450°C, anthracite IT2=830°C;

[0057] Lignite blending ratio R1 = 80%, anthracite blending ratio R2 = 20%,

[0058] Step 2: Calculate the weighted average pulverized coal airflow ignition temperature ITc (in °C) of the mixed coal after coal type 1 and coal type 2 are mixed. For the spec...

specific Embodiment example 3

[0077] Specific implementation case 3, the ignition temperature IT of pulverized coal airflow after the blending of typical lignite and bituminous coal, °C:

[0078] Step 1: Provide the ignition temperature IT1 (°C) of the pulverized coal flow of coal type 1 and the ignition temperature IT2 (°C) of the pulverized coal flow of coal type 2, the blending ratio R1 (%) of coal type 1 and the blending ratio of coal type 2 Combustion ratio R2 (%), wherein R1+R2=100%, wherein coal type 1 is the coal type with excellent ignition performance, that is, the ignition temperature of the pulverized coal flow of coal type 1 is lower than the ignition temperature of the pulverized coal flow of coal type 2;

[0079] Lignite IT1=380°C, anthracite IT2=640°C;

[0080] Lignite blending ratio R1 = 80%, anthracite blending ratio R2 = 20%,

[0081] Step 2: Calculate the weighted average pulverized coal airflow ignition temperature ITc (in °C) of the mixed coal after coal type 1 and coal type 2 are mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com