Turbomachinery variable working condition performance prediction method based on flow field reconstruction

A turbomachinery and performance prediction technology, applied in neural learning methods, neural architectures, special data processing applications, etc., can solve problems such as increased calculation costs and time-consuming, a large number of calculation operating points, and heavy workload of turbomachinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

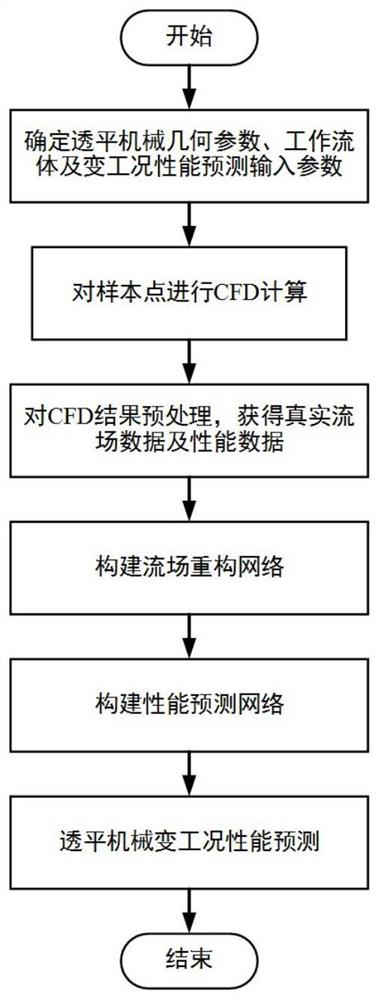

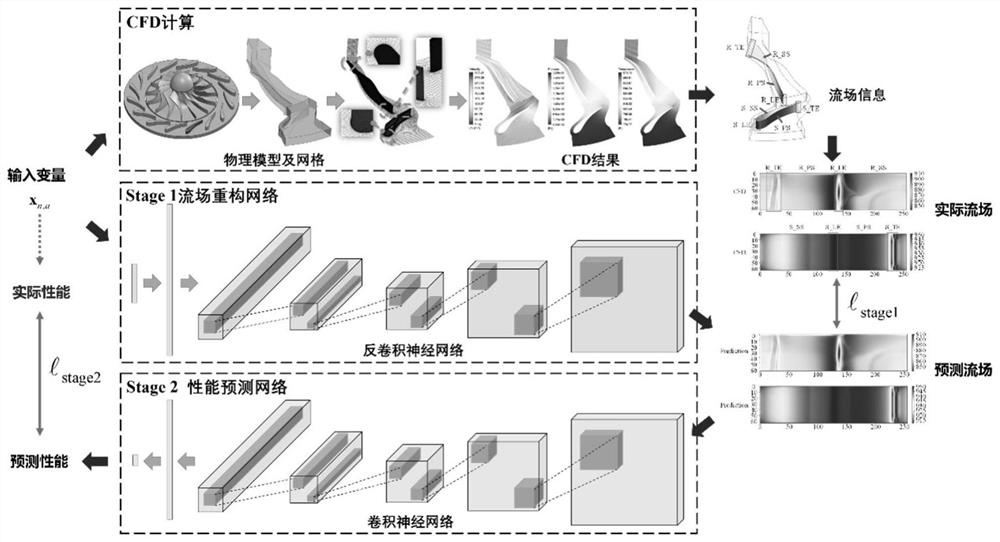

Method used

Image

Examples

Embodiment 1

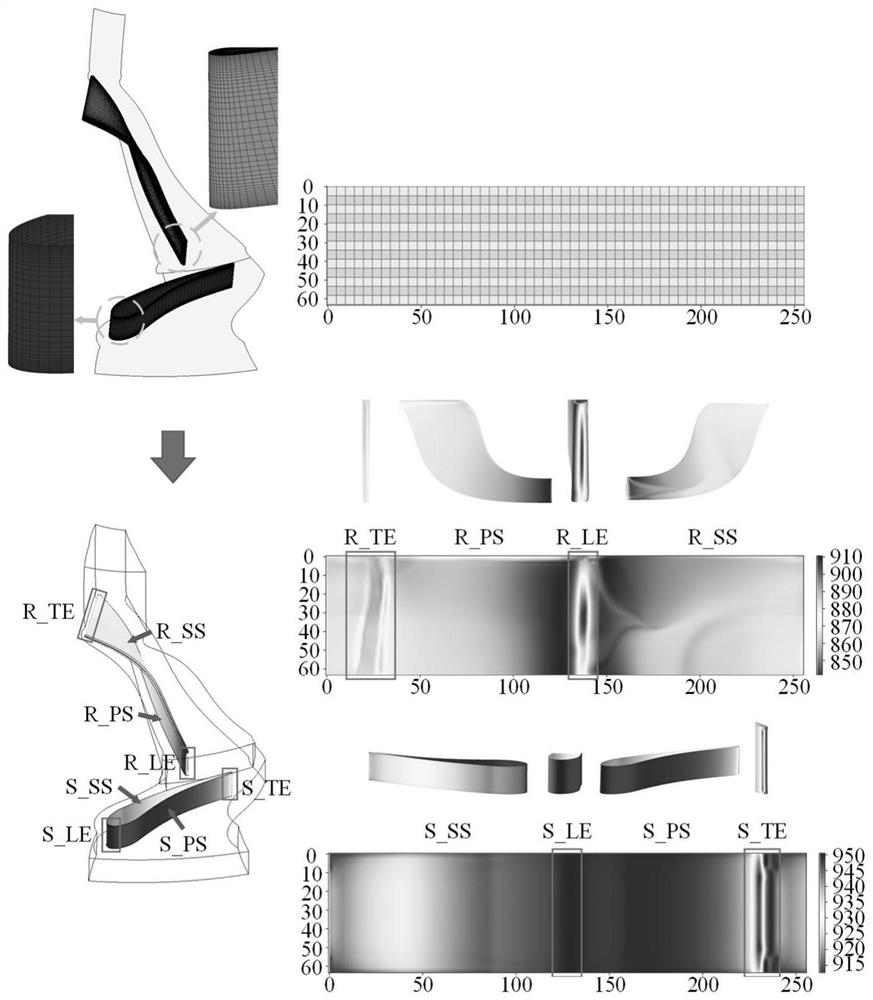

[0133] refer to Figure 3 to Figure 9 , using a method for predicting performance of turbomachinery under variable operating conditions based on flow field reconstruction of the present invention, a supercritical carbon dioxide centripetal turbine is predicted for variable operating conditions, as follows:

[0134] a) CFD variable working condition pre-analysis

[0135] First, based on the design experience, the aerodynamic design-optimization of a 60,000rpm supercritical carbon dioxide centripetal turbine was carried out. The key thermal parameters and geometric parameters are shown in Table 1.

[0136] Table 1 Thermal design parameters and geometric parameters

[0137]

[0138]

[0139] In order to calculate the variable operating condition performance of supercritical carbon dioxide centripetal turbine, the inlet temperature T in , inlet pressure P in , Inlet airflow angle α 1 ,Mass Flow and the turbomachinery speed ω R As an input variable, and make it change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com