CCS hot-pressing packaging type battery cell connecting assembly

A technology for connecting components and electrical connections, which is applied to battery pack components, electrical components, circuits, etc. It can solve the problems of exposed solder joints, long mold opening time, messy wires, etc., and achieves shortened mold opening cycle and fast mold opening Cost reduction and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

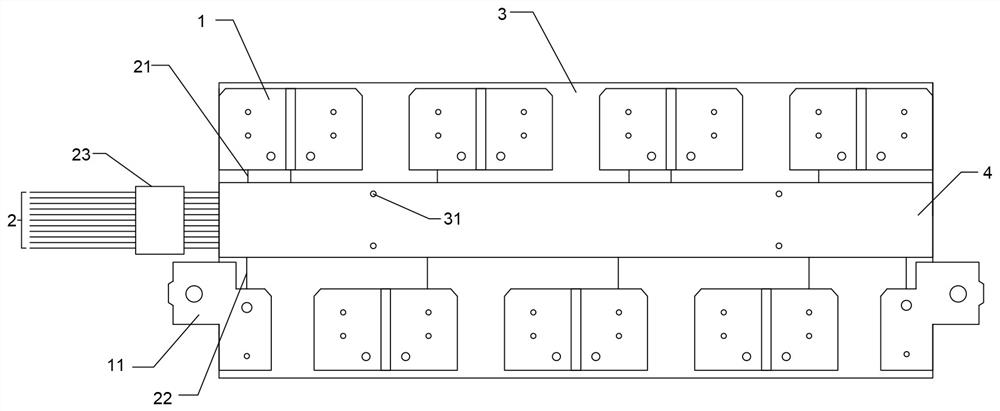

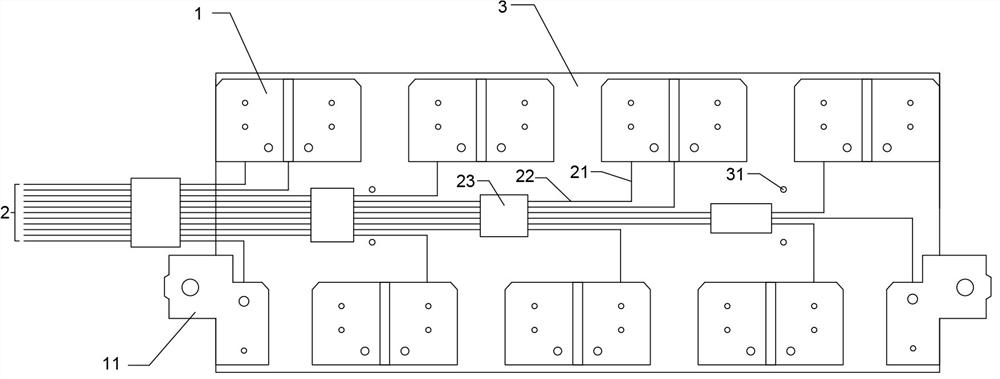

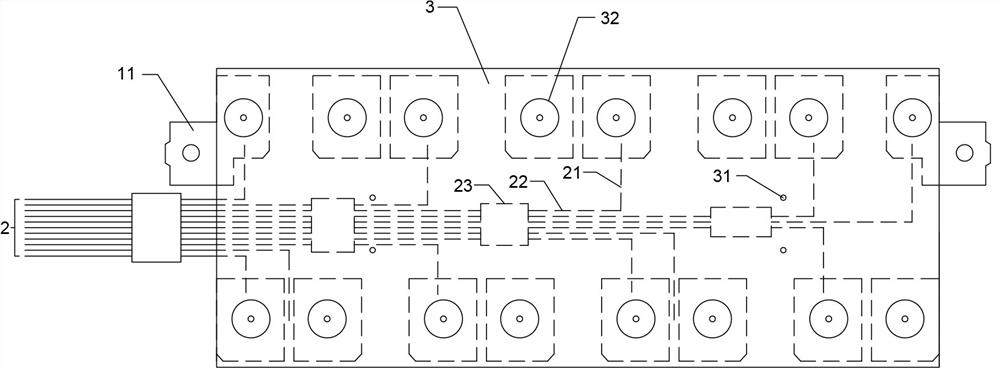

[0019] See figure 1 , figure 2 , image 3 ( image 3 The dotted part of the dotted line is actually the embossed outline of the aluminum bar 1 and the wire 2 seen from the back), an embodiment of a CCS thermocompression packaging type cell connection assembly, including multiple aluminum bars 1, correspondingly connected to The conductive circuit part 2 of the aluminum bar 1 and a heat-pressed film substrate 3, the conductive circuit part 2 in the figure is a wire. The aluminum bars 1 shown are arranged in two rows, and the aluminum bars are fixed on the hot-pressed film substrate 3 by hot pressing; in one row of aluminum bars 1, the two aluminum bars 1 at both ends are connected with external connection branches 11. It is used to connect and fix the output pole. On the external connection branch 11, a metal protection patch with a hardness high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com