Negative electrode lead plaster of storage battery with super-strong charging acceptance and preparation method thereof

A technology of acceptability and negative lead paste, applied in the direction of lead-acid battery electrodes, battery electrodes, negative electrodes, etc., can solve the problems such as the need to improve the charge acceptability, the unreasonable composition and proportion of lead paste, and improve the charging The effect of improved acceptance ability, charging acceptance ability and strong consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. The battery positive grid formula: tin Sn 1.2wt.%; calcium Ca 0.06wt.%, aluminum 0.02.0wt.%; the balance is lead.

[0059] Battery negative grid formula: tin Sn 1.2%; calcium Ca 0.03%, the balance is lead.

[0060] 2. Grid pretreatment

[0061] (1) The positive grid is hardened by normal age and operated according to the conventional method.

[0062] (2) Negative electrode grid pretreatment: After the grid is made, put the negative electrode grid in an aging hardening room for rapid aging, the aging temperature is 85°C, and the aging humidity is 70%. After ~9 hours, the hydrogen peroxide water vapor is made from a hydrogen peroxide aqueous solution with a content of 10-15%. After the time is over, it is naturally air-dried until there is no water vapor on the surface of the grid.

[0063] Use hydrogen peroxide water vapor to oxidize the surface of the grid at high temperature, increase the oxidation corrosion rate of the hydrogen peroxide on the plate, make the sur...

Embodiment 2

[0075] 1. The battery positive grid formula: tin Sn 1.2wt.%; calcium Ca 0.06wt.%, aluminum 0.02.0wt.%; the balance is lead.

[0076] Battery negative grid formula: tin Sn 1.2%; calcium Ca 0.03%, the balance is lead.

[0077] 2. Grid pretreatment

[0078] (1) The positive grid is hardened by normal age and operated according to the conventional method.

[0079] (2) Negative electrode grid pretreatment: same as embodiment 1.

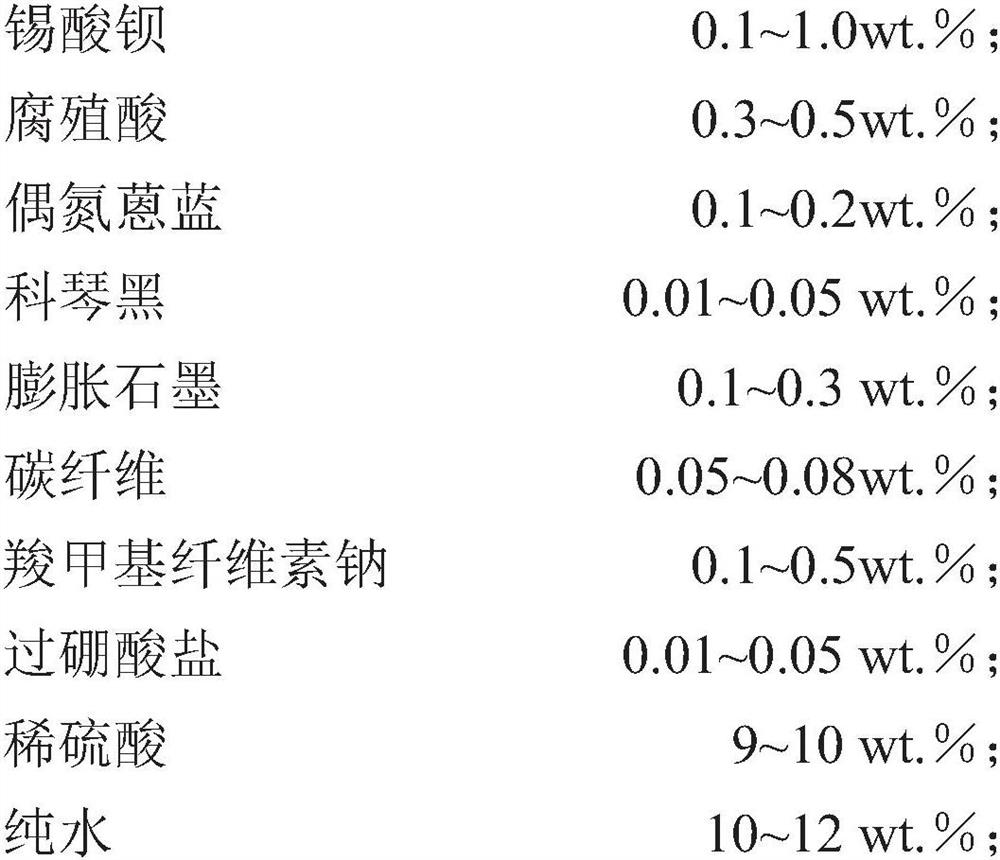

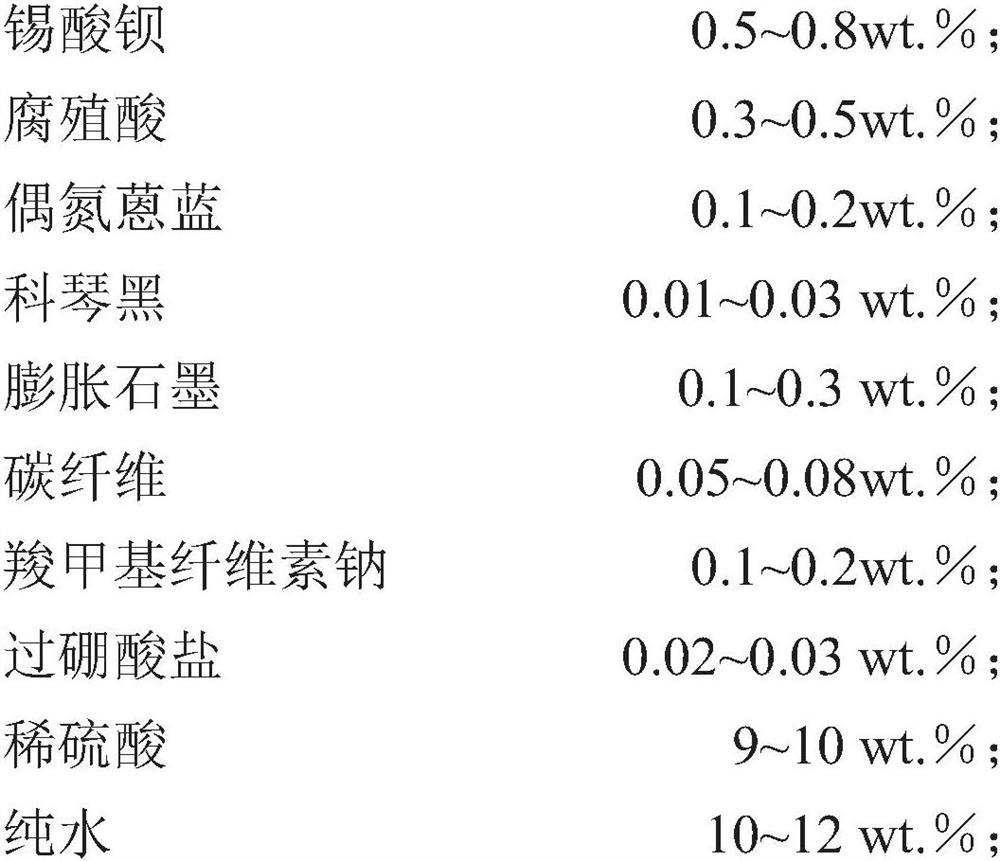

[0080] 3. Paste formula

[0081] Positive lead paste: its components and paste method are the same as in Comparative Example 1.

[0082] Negative lead paste: based on 100kg of raw materials, its components are: barium stannate 0.5kg; humic acid 0.5kg; azoanthracene blue 0.1kg; Ketjen black 0.01kg; expanded graphite 0.3kg; carbon fiber 0.08kg; Sodium methylcellulose (CMC) 0.2kg; Sodium perborate 0.03kg; Dilute sulfuric acid 9kg (density 1.4g / cm 3 ); 10kg of pure water; the balance is lead powder with an oxidation degree of 71% to 73%.

[0083] The pre...

Embodiment 3

[0085] 1. The battery positive grid formula: tin Sn 1.2wt.%; calcium Ca 0.06wt.%, aluminum 0.02.0wt.%; the balance is lead.

[0086] Battery negative grid formula: tin Sn 1.2%; calcium Ca 0.03%, the balance is lead.

[0087] 2. Grid pretreatment

[0088] (1) The positive grid is hardened by normal age and operated according to the conventional method.

[0089] (2) Negative electrode grid pretreatment: same as embodiment 1.

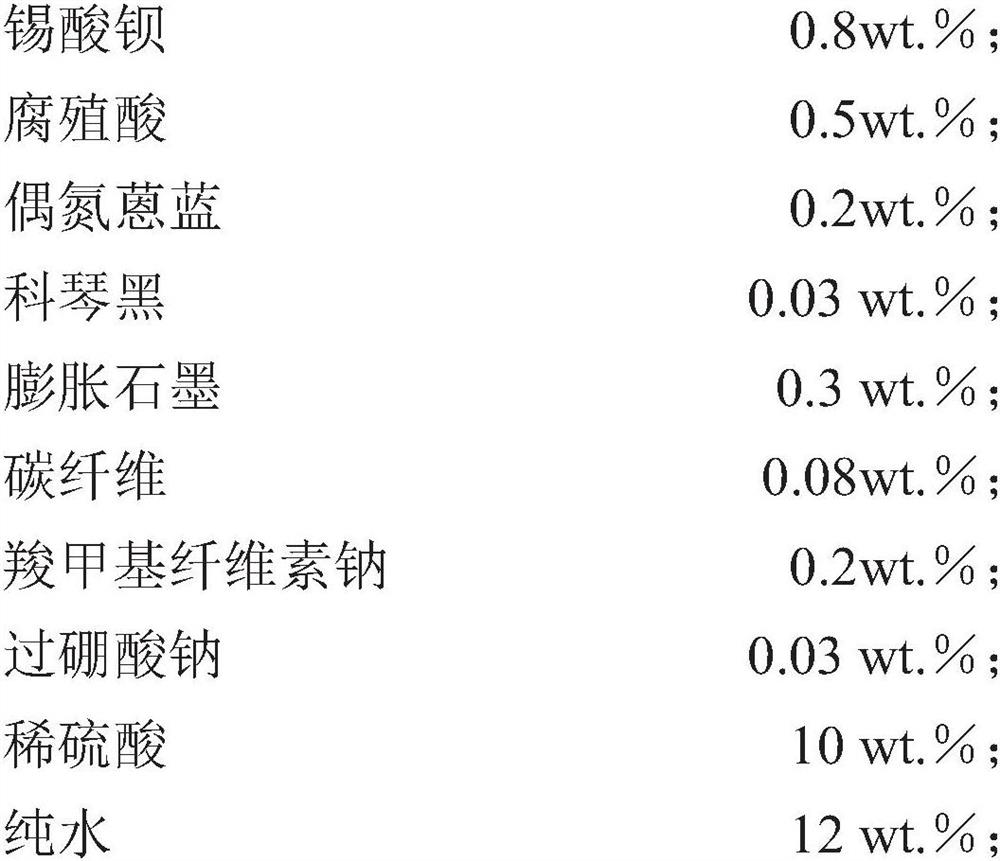

[0090] 3. Paste formula

[0091] Positive lead paste: its components and paste method are the same as in Comparative Example 1.

[0092] Negative lead paste: based on 100kg of raw materials, its components are: barium stannate 0.8kg; humic acid 0.5kg; azoanthracene blue 0.2kg; Ketjen black 0.03kg; expanded graphite 0.3kg; carbon fiber 0.08kg; Sodium methylcellulose (CMC) 0.2kg; Sodium perborate 0.03kg; Dilute sulfuric acid 10kg (density 1.4g / cm 3 ); 12kg of pure water; the balance is lead powder with an oxidation degree of 71 to 73%.

[0093] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com