Dye blending device for textile production

A technology for textiles and dyes, which is applied in the field of dye leveling devices for textile production, which can solve the problems of reduced dye blending efficiency and increased dye dissolution, and achieve the effects of improving dye blending efficiency, improving efficiency and quality, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

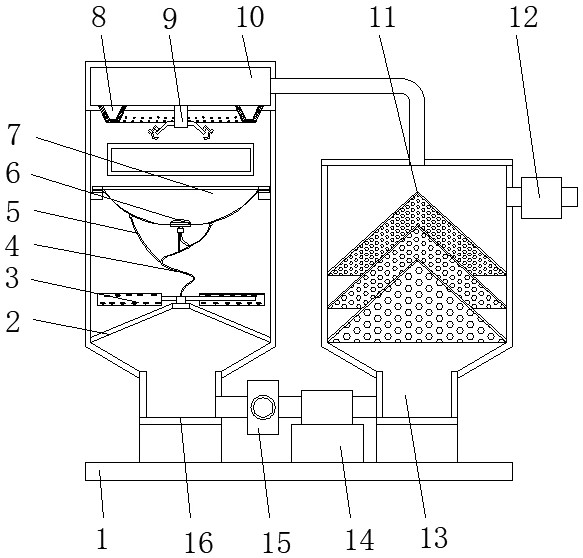

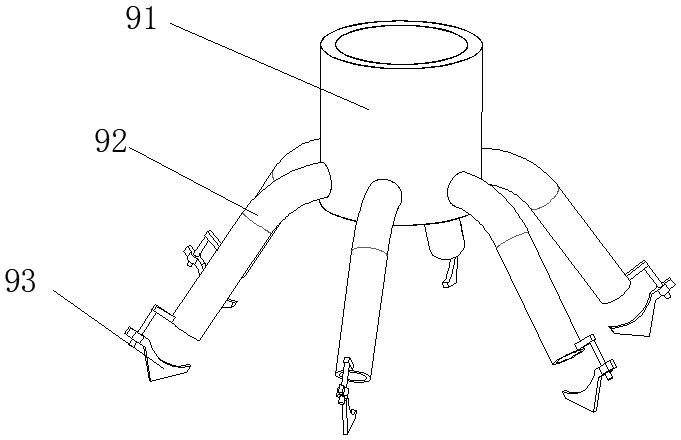

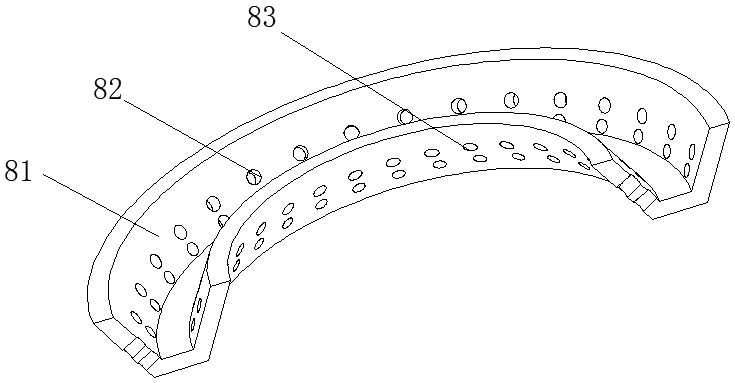

[0027] refer to Figure 1-5 , a dye mixing device for textile production, comprising a base 1, a mixing tank 16 and a discharge tank 13 are fixedly installed on the top of the base 1, and a discharge valve 12 is fixedly installed on the side of the discharge tank 13, and the mixing tank 16 A transparent feed sealing plate is installed at the end of the tank through a hasp lock and a hinge, and a three-way valve 15 and a delivery pump 14 are installed through a pipeline between the mixing tank 16 and the discharge tank 13, and one end of the three-way valve 15 is fixedly installed There is a liquid injection pipe, the top of the mixing tank 16 is fixedly equipped with a liquid inlet housing 10, and the top of the discharge tank 13 is connected with the side of the liquid inlet housing 10 through a pipeline, and the bottom of the liquid inlet housing 10 is fixedly installed with a spray Drenching mechanism 9, the internal bottom of mixing tank 16 is fixedly installed with suppor...

Embodiment 2

[0037] refer to Figure 1-5 , a dye leveling device for textile production. Compared with Embodiment 1 in this embodiment, a plurality of annularly distributed support rods are fixedly installed on the outer side of the lower cylinder of the elastic body 4, and an arc-shaped structure is fixedly installed on the side of the support rods. The scour plate 3, the surface of the scour plate 3 is provided with a plurality of through holes.

[0038] When this embodiment is in use, the surface of the scouring plate 3 is impacted during the solution’s falling process, and the elastic body 4 is driven to rotate by the scouring plate 3, further aggravating the shaking degree of the elastic body 4, and the scouring plate 3 can shake the bottom layer during the rotation process. The solution is stirred to improve the absorption efficiency of the dye powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com