Coating powder composition and method for preparing coating

A composition, powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as damage, decrease in fastener preload, and decrease in mechanical properties of fasteners at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] 1) formulate the coating powder composition shown in table 1, then put into container;

[0078] 2) adding anhydrous ethanol which is 1 times the volume of the above powder composition into the container as a carrier;

[0079] 3) Add 1.2wt% polyethylene glycol of the mass of the above-mentioned powder composition into the container as a binding agent;

[0080] 4) The above materials are made into slurry after high-speed ball milling, the ball milling speed is 150r / min, and the ball milling time is 10h;

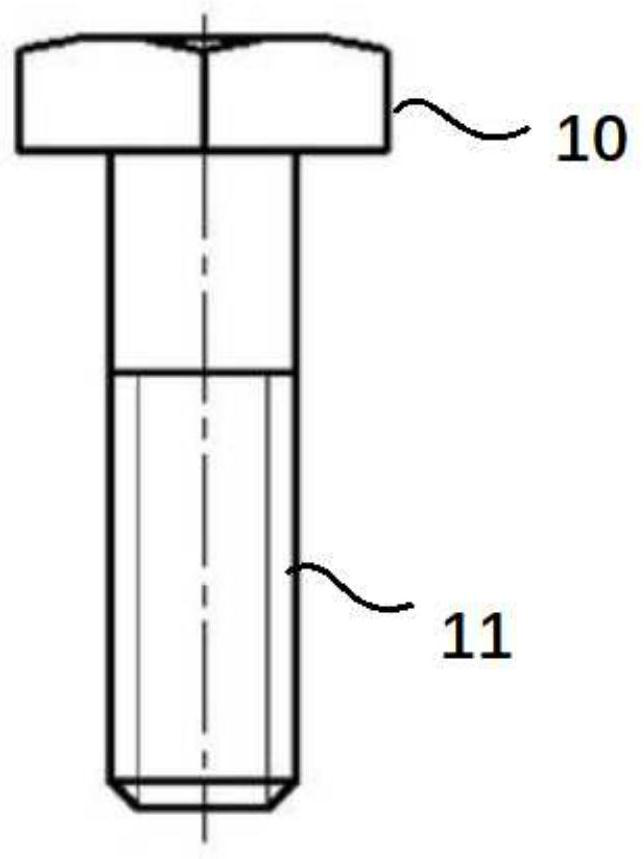

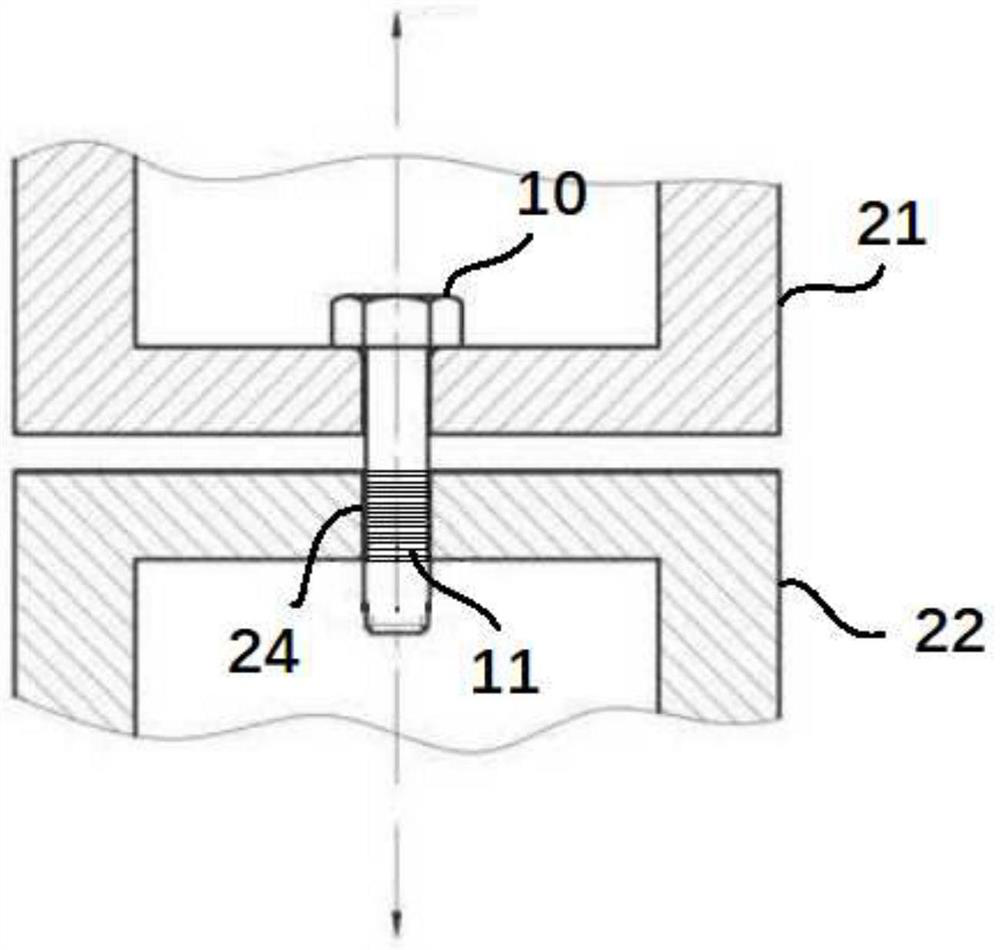

[0081] 5) The fastener (blank sample) made of the NbW5-1 alloy of Comparative Example 1 was completely immersed in the slurry for 5 seconds, then taken out, and dried in a ventilated environment for 10 minutes;

[0082] 6) Place the fasteners coated with the slurry on the surface in a vacuum resistance furnace for sintering at high temperature and in a vacuum environment (1550° C., below 0.1 Pa). After sintering, a high temperature resistant and oxidation resistant coat...

Embodiment 2

[0085] 1) formulate the coating powder composition shown in table 1, then put into container;

[0086] 2) adding anhydrous ethanol which is 1 times the volume of the above powder composition into the container as a carrier;

[0087] 3) Add polyethylene glycol (molecular weight 6000) of 5wt% of the mass of the above-mentioned powder composition into the container as a binding agent;

[0088] 4) The above materials are made into slurry after high-speed ball milling, the ball milling speed is 450r / min, and the ball milling time is 3.5h;

[0089] 5) The fastener (blank sample) made of the NbW5-1 alloy of Comparative Example 1 was completely immersed in the slurry for 10 seconds, then taken out, and dried in a ventilated environment for 45 minutes;

[0090] 6) Place the fasteners coated with the slurry on the surface in a vacuum resistance furnace for sintering at high temperature and in a vacuum environment (1550° C., below 0.1 Pa). After sintering, a high temperature resistant a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com