A kind of anti-aging PC sunshine board and preparation method thereof

A technology of sunlight board and aging resistance, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of short service life, yellowing and aging of sunlight boards, etc. The effect of aging resistance, enhanced UV resistance, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

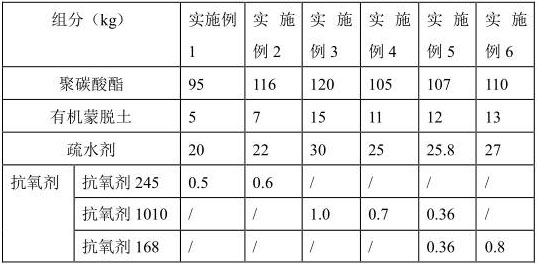

Examples

Embodiment 1- Embodiment 6

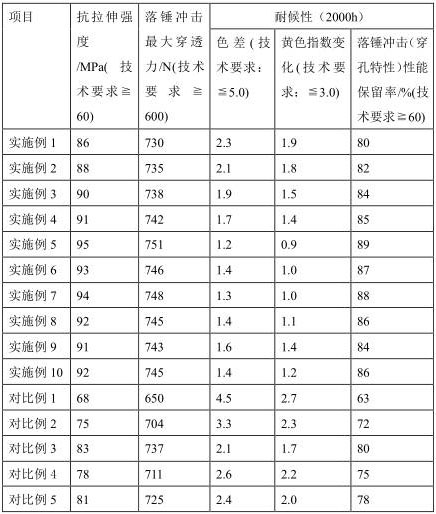

[0053] The preparation methods of the PC solar panels in Example 1-Example 6 are all the same, the only difference is that the types and dosages of the raw material components in the main material layer are different, see Table 2 for details:

[0054] Table 2, the type and dosage of raw material components in the main material layer

[0055]

[0056] The hydrophobic agent in Example 1-Example 6 includes polyvinyl fluoride and ethylene-tetrafluoroethylene copolymer in a weight ratio of 1.3:2.5.

[0057] The thickness of anti-ultraviolet layer in embodiment 1-embodiment 6 is 50 μ m, the raw material of anti-ultraviolet layer in embodiment 1-embodiment 3 is phenyl o-hydroxybenzoate, the thickness of anti-ultraviolet layer in embodiment 4-embodiment 6 The starting material is 2-hydroxy-4-n-octyloxybenzophenone.

[0058]Taking Example 5 as an example to illustrate the preparation method of PC solar panels, it may further comprise the steps:

[0059] S1. According to the propor...

Embodiment 7

[0062] The difference between this embodiment and embodiment 5 is that the hydrophobic agent includes polyvinyl fluoride and ethylene-tetrafluoroethylene copolymer in a weight ratio of 1:2.

Embodiment 8

[0064] The difference between this embodiment and embodiment 5 is that the hydrophobic agent includes polyvinyl fluoride and ethylene-tetrafluoroethylene copolymer in a weight ratio of 1.5:2.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com