Water-soluble fertilizer filling equipment

A filling equipment and water-soluble fertilizer technology, applied in the field of water-soluble fertilizer filling equipment, can solve problems such as easy generation of large bubbles, product outer packaging pollution, and inaccurate packaging dosage, so as to avoid overflow and waste and improve the quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

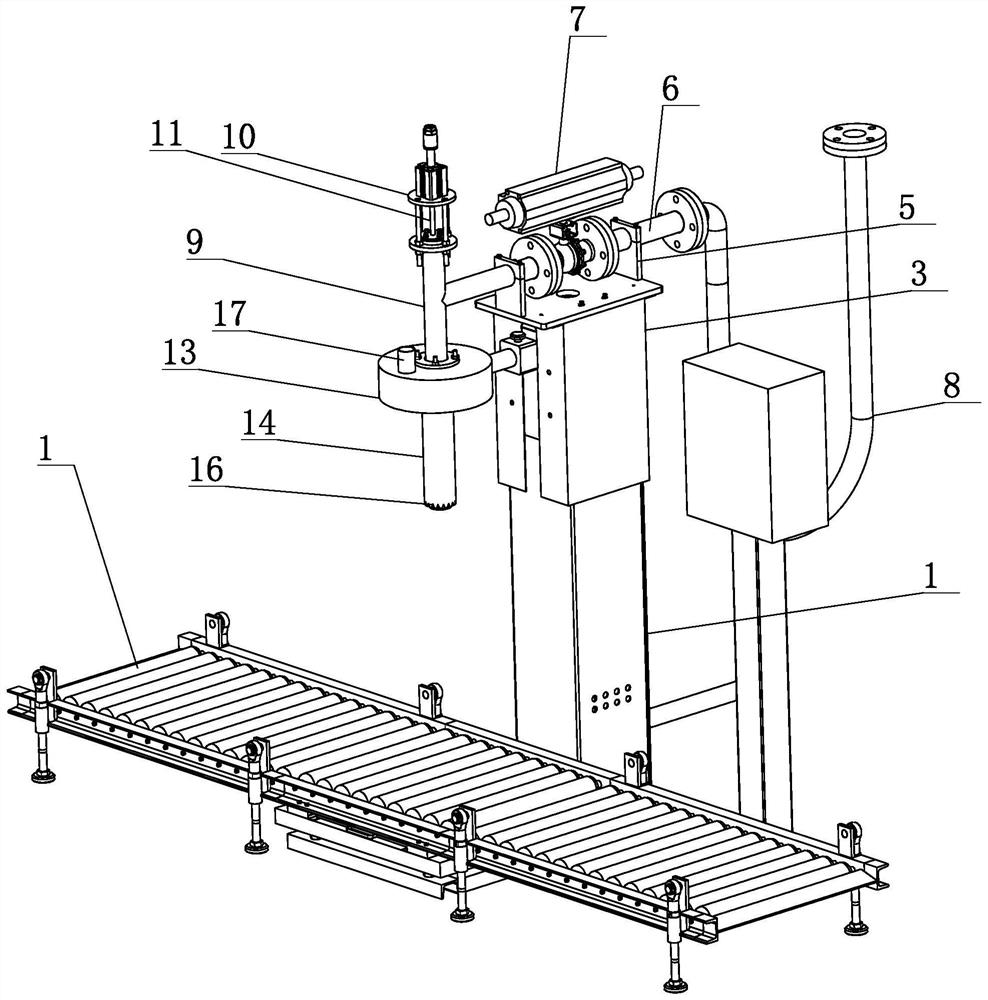

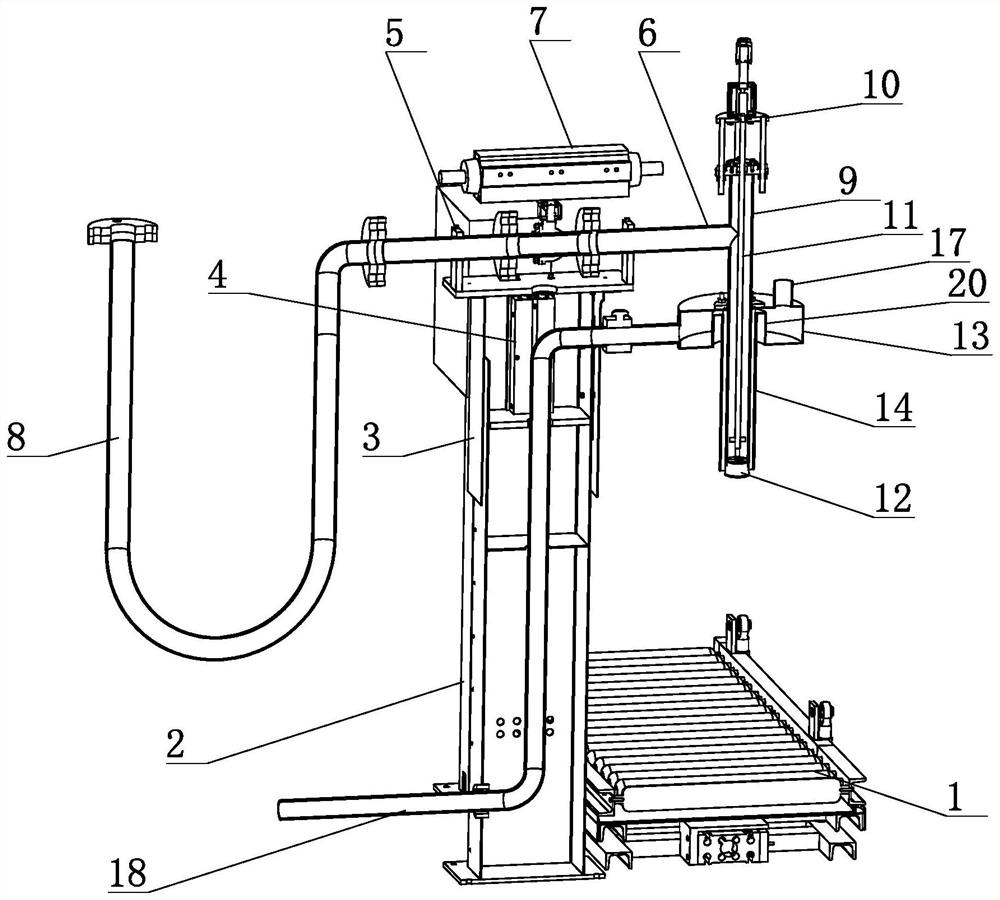

[0028] Embodiment 1: A kind of water-soluble fertilizer filling equipment

[0029] The filling machine includes conveying mechanism 1, liquid injection mechanism, control box

[0030] 1) Conveying mechanism 1

[0031] The conveying mechanism 1 is a linear conveying mechanism 1, and common conveying structures can be used, such as belts, rollers, etc.; There are flat rollers installed in the length direction, and the two ends of the flat rollers are rotatably matched with the frame frame. The two ends of the flat rollers are provided with sprockets, and all the sprockets are wound with a circle of chains. . A conveying motor is installed at the bottom of the frame, and the conveying motor conveys the parallel rollers through the chain to realize the conveying of packaging containers such as packaging drums and packaging cans.

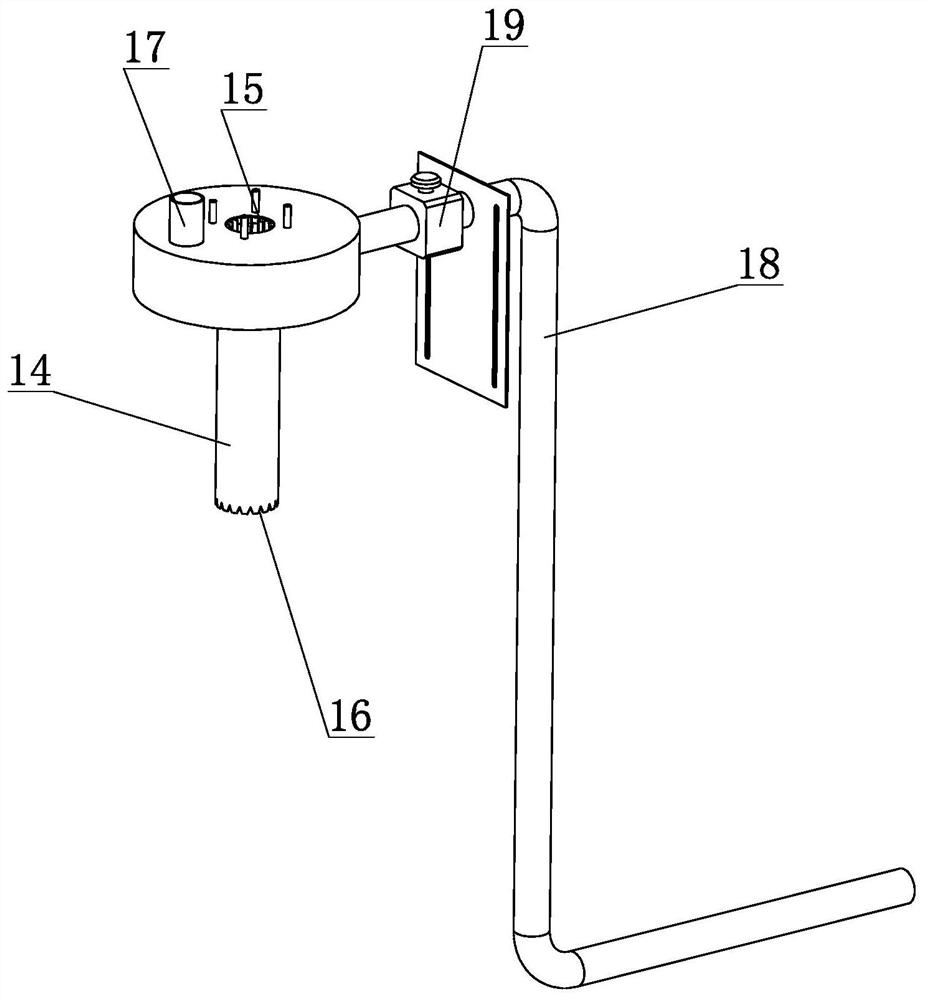

[0032] 2) Liquid injection mechanism

[0033] The liquid injection mechanism includes a vertically extending sliding seat 2, the sliding seat 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com