Self-healing porcelain insulator and manufacturing method thereof

A technology of insulators and calcium lactate, applied in the direction of insulators, insulators, clay products, etc., can solve problems such as repeated tripping of lines and affect power supply, achieve the effect of restoring insulation strength, improving power supply reliability, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

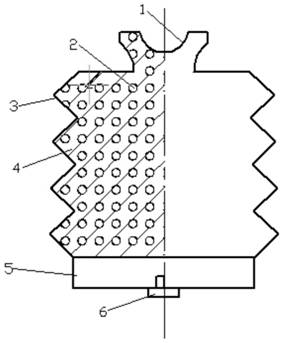

[0037] Such as figure 1 As shown, this embodiment provides a self-healing porcelain insulator, comprising: Bacillus capsules 2 and calcium lactate porcelain body 4; the Bacillus capsules 2 are evenly distributed inside the calcium lactate porcelain body 4;

[0038] The bacillus capsule 2 includes a capsule skin and a bacillus group, and the capsule skin wraps the bacillus group;

[0039] The calcium lactate porcelain body 4 is a structure in which calcium lactate and urea are distributed inside.

[0040] It should be noted that when the insulator is damaged, the bacillus capsule 2 is activated by the moisture in the air. After activation, the capsule skin decomposes, and the bacillus group in the capsule engulfs the calcium lactate and urea in the calcium lactate porcelain body 4 to rapidly multiply to produce filling material, so as to quickly repair the damaged part of the insulator and restore the insulation strength.

[0041] It should be noted that there is no differenc...

Embodiment 2

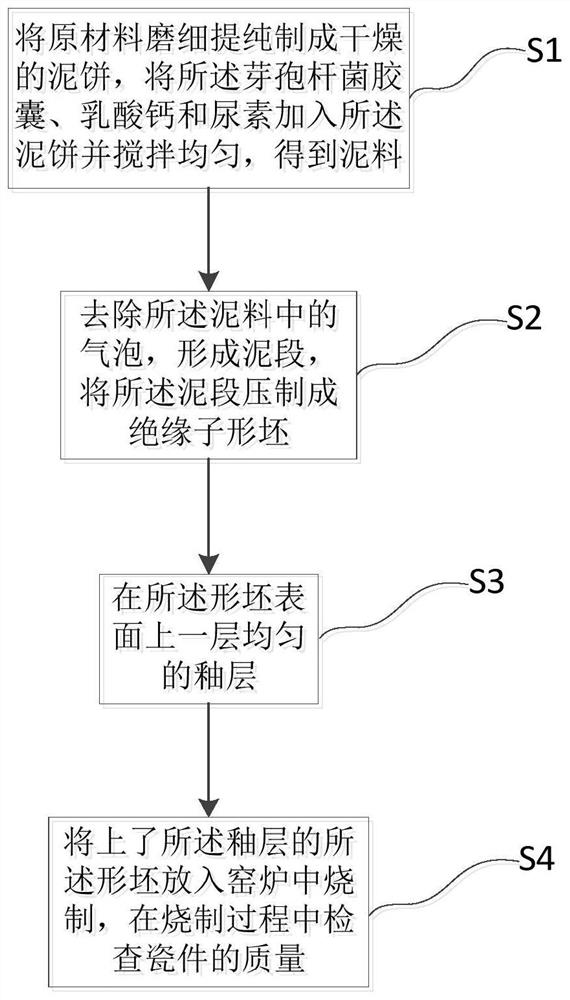

[0052] Such as figure 2 As shown, this embodiment provides a method for manufacturing the self-healing porcelain insulator in Embodiment 1, including the following steps:

[0053] S1: Grinding and purifying the raw materials to make a dry mud cake, adding the Bacillus capsule 2, calcium lactate and urea to the mud cake and stirring evenly to obtain a mud cake;

[0054] S2: removing air bubbles in the mud material to form a mud section, and pressing the mud section into an insulator blank;

[0055] S3: a uniform glaze layer on the surface of the shape;

[0056] S4: Put the shape body covered with the glaze layer into a kiln for firing, and check the quality of the porcelain piece during the firing process.

[0057] It should be noted that, adopting the manufacturing method of the present invention, first grind and purify pottery stone, feldspar, clay and alumina raw materials, use a ball mill to grind the raw materials with water, and mix them evenly; then remove large particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com