Core-shell structure nano composite particle system with gradient-changing shell-core ratio and preparation method thereof

A gradient change and nano-composite technology, applied in the core-shell structure nano-composite particle system and its preparation field, can solve the problems of complex synthesis process and difficulty in large-scale production, and achieve low cost, novel preparation method and short cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

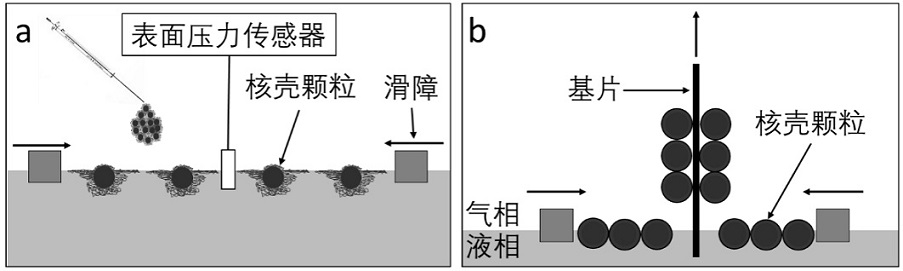

Method used

Image

Examples

Embodiment 1

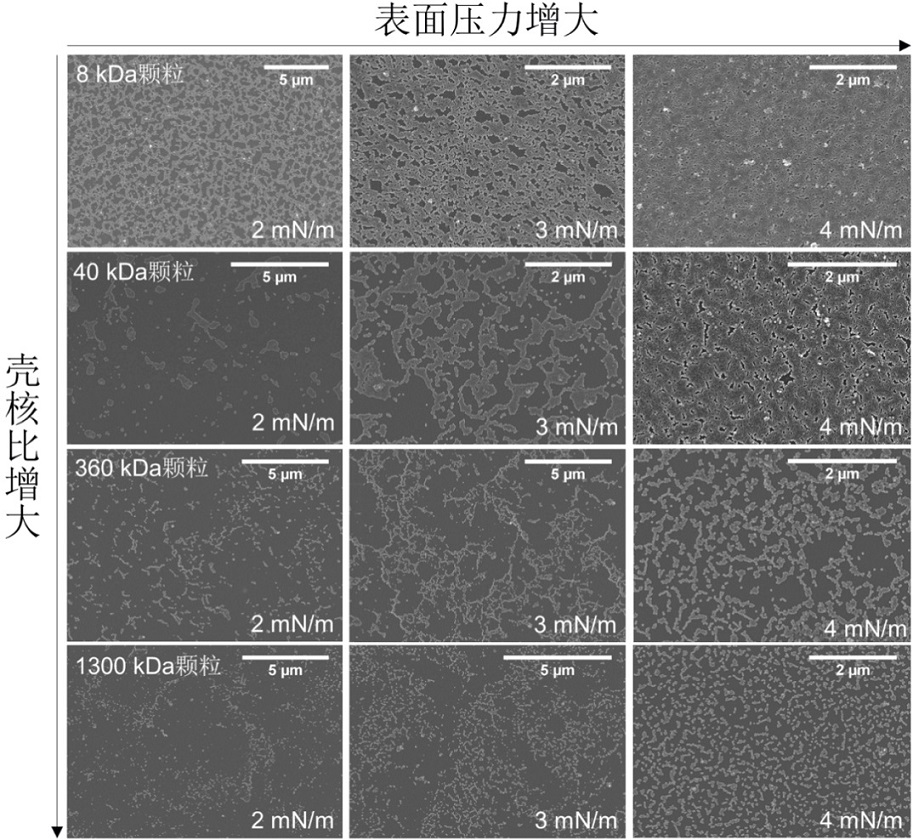

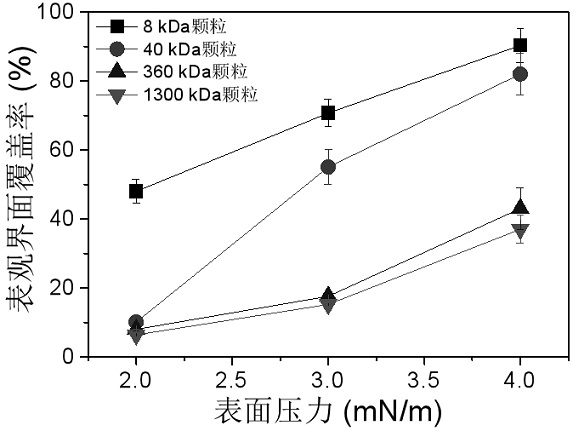

[0051] This implementation case shows a preparation method of a core-shell structure nanocomposite particle system with a gradient change in the core-shell ratio according to the following steps:

[0052] A PVP and Ludox AS40 SiO with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa 2 The steps of preparing a core-shell structure nanocomposite particle system with a gradient change in shell-core ratio as raw materials are as follows:

[0053] (1) Prepare four PVP solutions with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa respectively, with a volume of 200ml and a concentration of 0.1wt%.

[0054] (2) Prepare four 150 ml portions of SiO with a concentration of 0.2wt% 2 nanoparticle dispersion.

[0055] (3) The above four SiO 2 The nanoparticle dispersion was added dropwise into four vigorously stirred PVP solutions with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa, the stirring rate was 300 rpm, and the stirring was continued for 8 h to ensur...

Embodiment 2

[0062] This implementation case shows a preparation method of a core-shell structure nanocomposite particle system with a gradient change in the core-shell ratio according to the following steps:

[0063] A PVP and Ludox AS40 SiO with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa 2 The steps of preparing a core-shell structure nanocomposite particle system with a gradient change in shell-core ratio as raw materials are as follows:

[0064] (1) Prepare four PVP solutions with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa respectively, with a volume of 200ml and a concentration of 0.1wt%.

[0065] (2) Prepare four 150 ml portions of SiO with a concentration of 0.2wt% 2 nanoparticle dispersion.

[0066] (3) The above four SiO 2 The nanoparticle dispersion was added dropwise into four vigorously stirred PVP solutions with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa, the stirring rate was 800 rpm, and the stirring was continued for 5 h to ensur...

Embodiment 3

[0072] A PVP and Ludox AS40 SiO with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa 2 The steps of preparing a core-shell structure nanocomposite particle system with a gradient change in shell-core ratio as raw materials are as follows:

[0073] (1) Prepare four PVP solutions with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa respectively, with a volume of 200ml and a concentration of 0.1wt%.

[0074] (2) Prepare four 150 ml portions of SiO with a concentration of 0.2wt% 2 nanoparticle dispersion.

[0075] (3) The above four SiO 2 The nanoparticle dispersion was added dropwise into four vigorously stirred PVP solutions with molecular weights of 8 kDa, 40 kDa, 360 kDa and 1300 kDa, the stirring rate was 500 rpm, and the stirring was continued for 1 h to ensure that the SiO 2 The surface of the nanoparticles is completely adsorbed by PVP. After the adsorption is completed, the four PVP-SiO 2 The nanoparticle dispersion was centrifuged for 4 hours, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com