Butt-joint structure and butt-joint method for two plates with different thicknesses

A technology of plates with different thicknesses, applied in building construction, construction, etc., can solve the problems of large consumables, weak welding, stress concentration, etc., achieve the effects of less material loss, ensure docking stability, and reduce stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

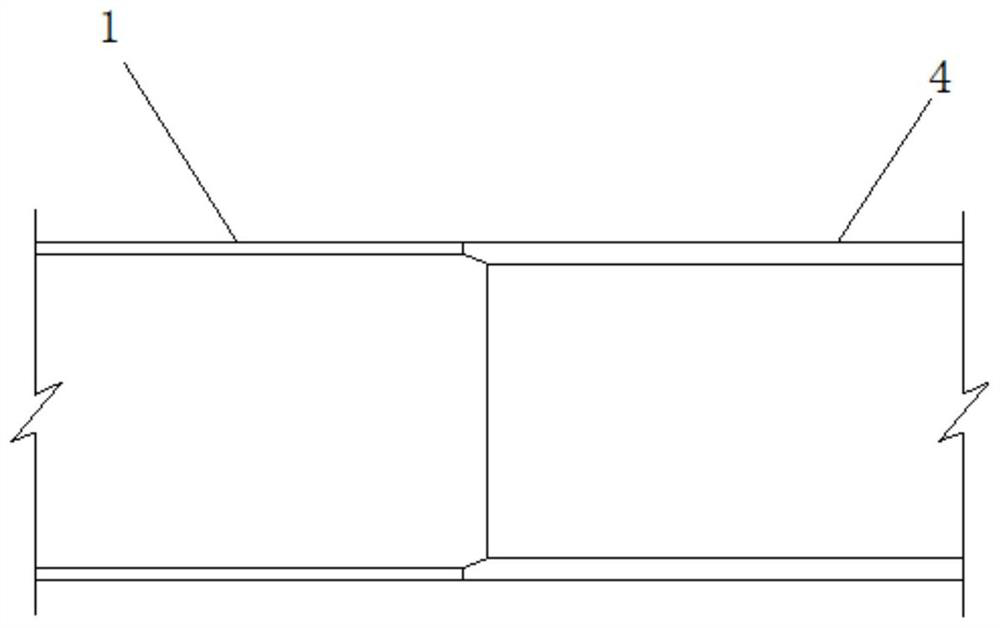

[0047] Such as Figures 1 to 4 A specific implementation of the method for joining two plates with different thicknesses shown includes the following steps: setting the cutting speed to 200mm / min, the height of the cutting torch to 100mm, and the pressure of oxygen to 0.9Mpa.

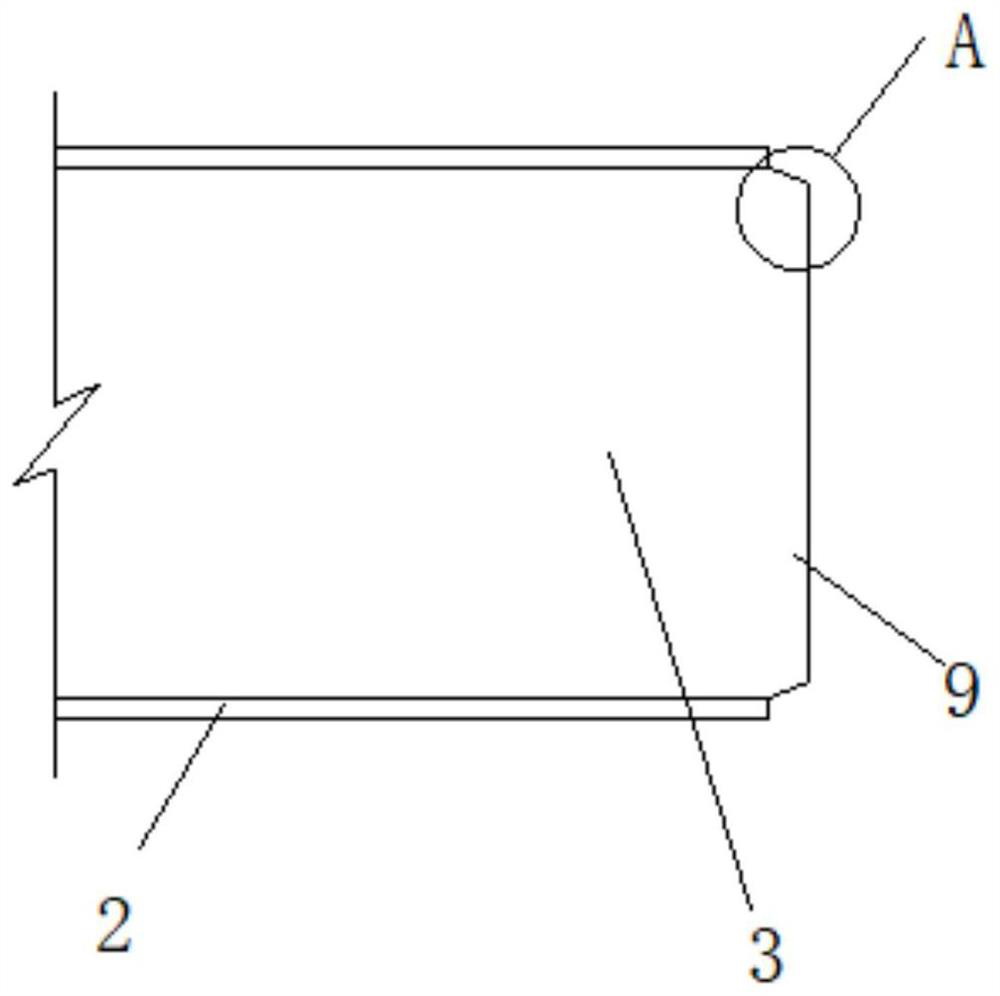

[0048] The two adjacent corners of the prefabricated board are cut according to the preset size to form the first web 3 with the first splicing surface and two first transition slopes, the length of the first web 3 is longer than the first The length of the wing plate 2, a pair of prefabricated first wing plates 2 are vertically welded on the opposite sides of the first web 3 respectively to form the first plate 1 of the "I" shape structure, and the first web 3 protrudes Parts of a pair of first wing plates 2 form a first connecting portion 9;

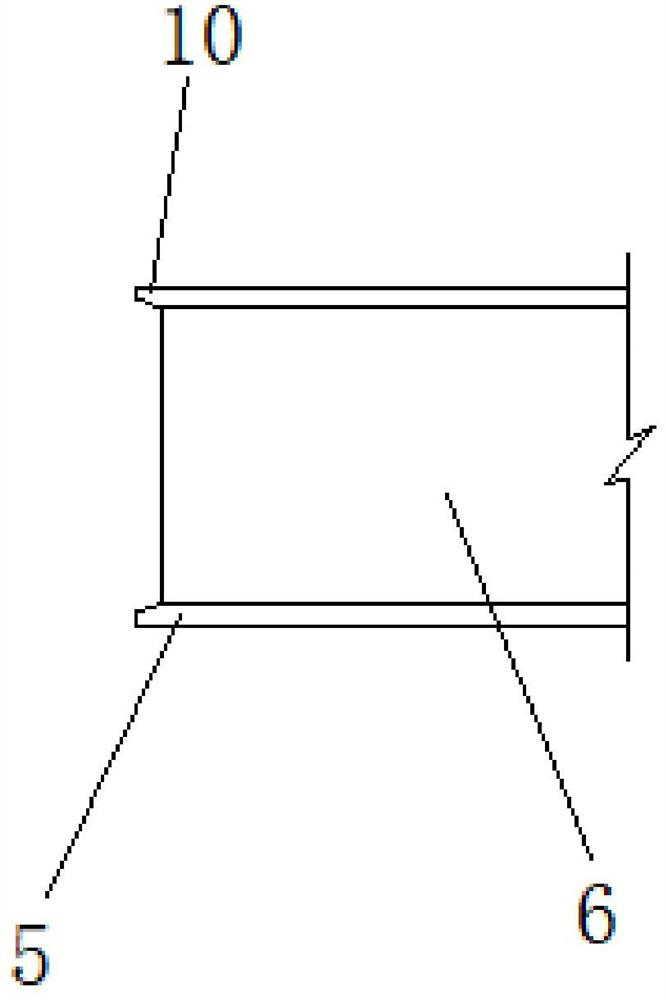

[0049] A corner of the prefabricated plate is cut according to a preset size to form a second wing plate 5 having a second splicing surface and a second transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com