Compressor, control method and air conditioner

A compressor and control valve technology, applied in the field of compressors, can solve the problem that the bearing temperature cannot be guaranteed at the same time, and will not be too high, and achieve the effect of avoiding excessive suction superheat and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

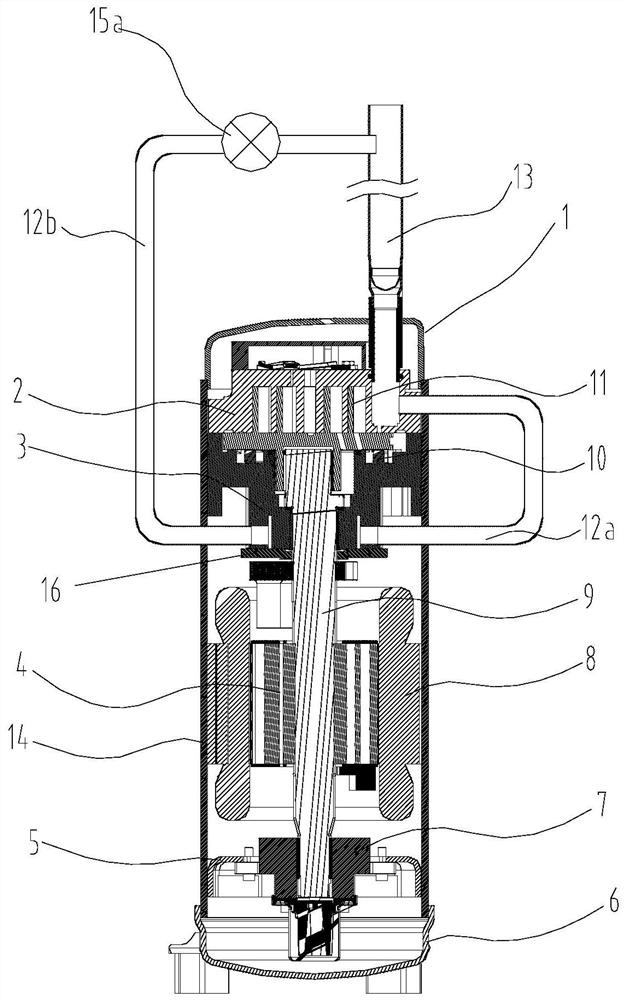

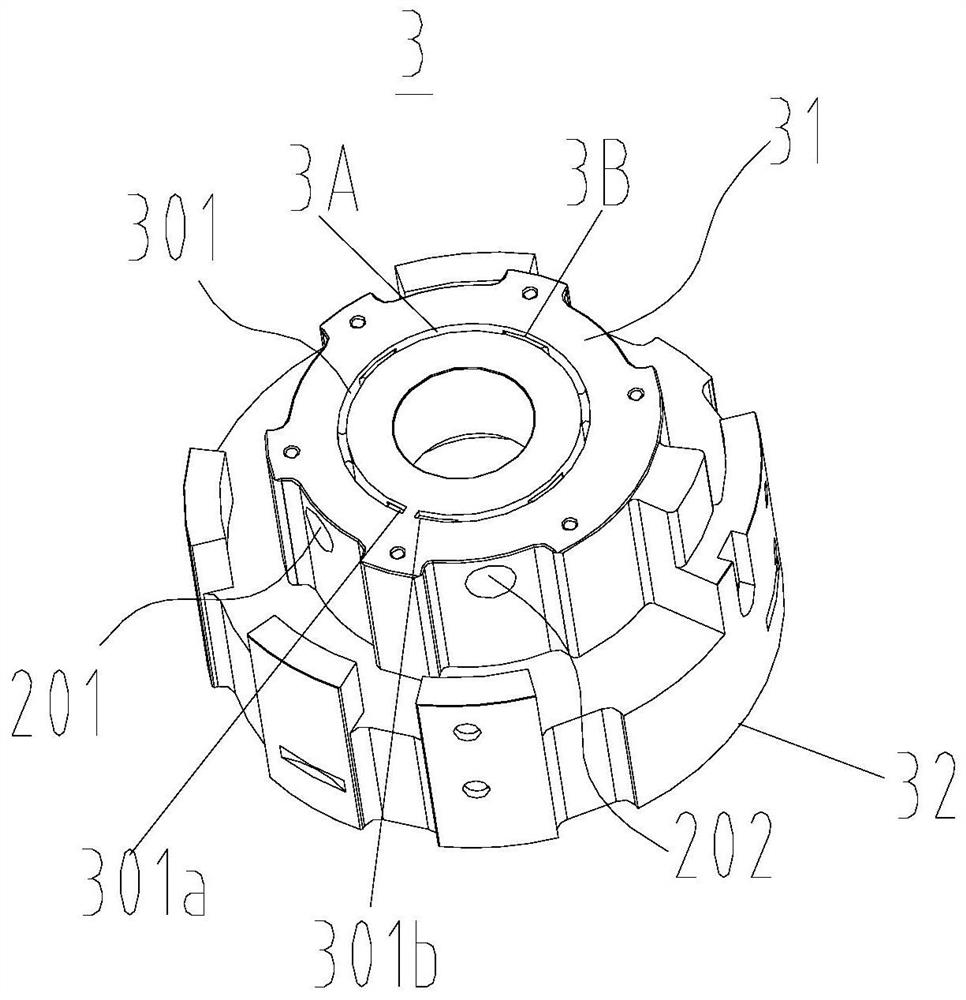

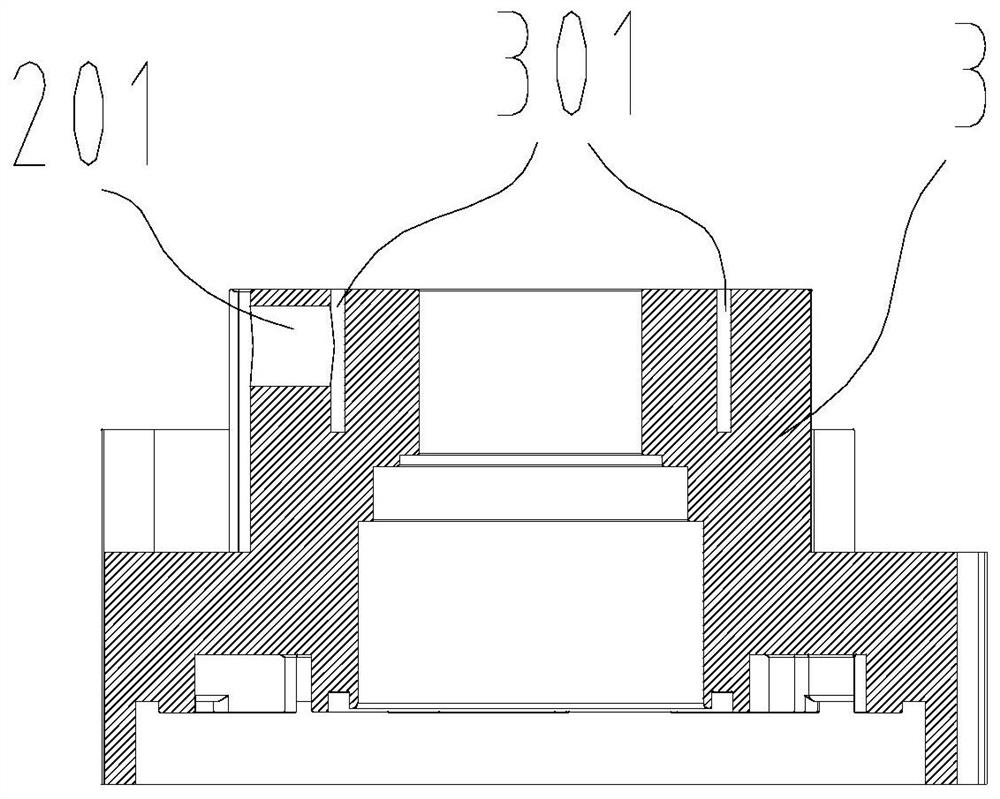

[0045] Embodiment one, in figure 1 Here, the present invention sets a first bypass pipeline 12a and a second bypass pipeline 12b outside the compressor. The side through hole 401 of the fixed scroll 2 communicates with the suction port 501 above the fixed scroll 2 (such as Figure 4 and Figure 5 ). Air inlet 201 and air outlet 202 are provided on the side of upper support 3, and a cooling chamber (inner channel 301) coaxial with the bearing hole is set on upper support 3, and air inlet 201 and air outlet 202 communicate with the cooling chamber ( Such as image 3 ), the cooling chamber is not connected at the gas inlet 201 and the gas outlet 202 where the gas travel arc is small (that is, the internal channel is not fully connected, and the cross section is a superior arc structure), after the gas enters the cooling chamber through the inlet 201 , it is necessary to go through a larger arc to leave the cooling chamber from the air outlet 202. The cooling chamber is divide...

Embodiment 2

[0046] Embodiment two, Figure 7 It is a schematic diagram of the overall structure of an alternative embodiment, and a second control valve 15b (preferably a one-way valve) is provided on the first bypass line 12a. Figure 8 It is a schematic diagram of the second implementation case of the bearing cooling chamber of the upper bracket, which communicates with the air inlet 201 and the air outlet 202 of the upper bracket 3 respectively, and the cooling chamber is located at the place where the air inlet 201 and the air outlet 202 have a smaller gas travel arc. If it is not connected, after the gas enters the cooling chamber through the air inlet 201, it needs to go through a large arc to leave the cooling chamber from the air outlet 202. The cooling chamber is a circular groove, Figure 9 It is a system schematic diagram of an alternative embodiment. The specific working principle is that after the refrigerant flows out of the evaporator, part of the refrigerant directly enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com