Assembly type casing pipe, monitoring system applying casping pipe and sewage leakage monitoring method

A monitoring system and assembled technology, which is applied in the field of pipeline surveying and mapping, can solve problems such as incompetence, and achieve the effects of convenient and fast assembly, strong operability, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

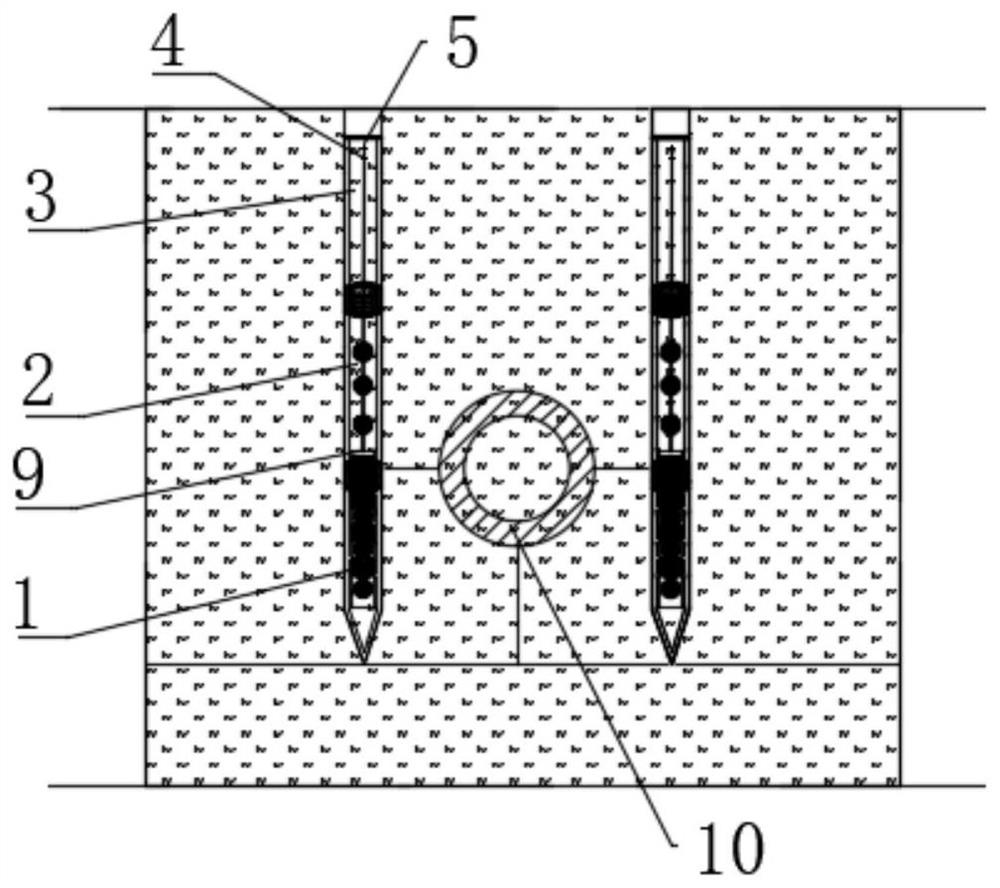

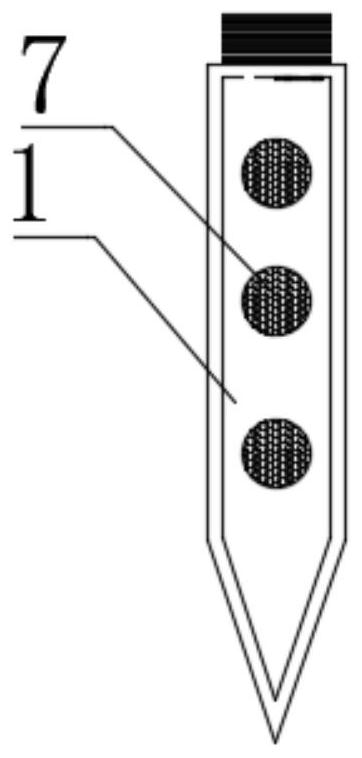

[0027] A fabricated casing such as figure 1 As shown in FIG. 3 , it includes a cone head, an extension tube is threaded on the top of the cone head, and a top sealing pipe is threaded on the end of the extension tube away from the cone head. In this embodiment, all the detachable components are screwed. When in use, the cone head is used to insert into the ground, and the tip of the cone head faces the ground; the cavity of the cone head, the cavity of the extension tube and the cavity of the top sealing tube are all connected, and the cone head, the extension tube, and the top sealing tube are installed to form a hollow tube body; and The outer wall of the assembled casing is provided with permeable holes that allow water seepage;

[0028] A sensor is provided in the casing, and the sensor is used for measuring the height of the water level penetrating into the assembled casing. There is a power line connector, an information transmission line connector and a suction pipe o...

Embodiment 2

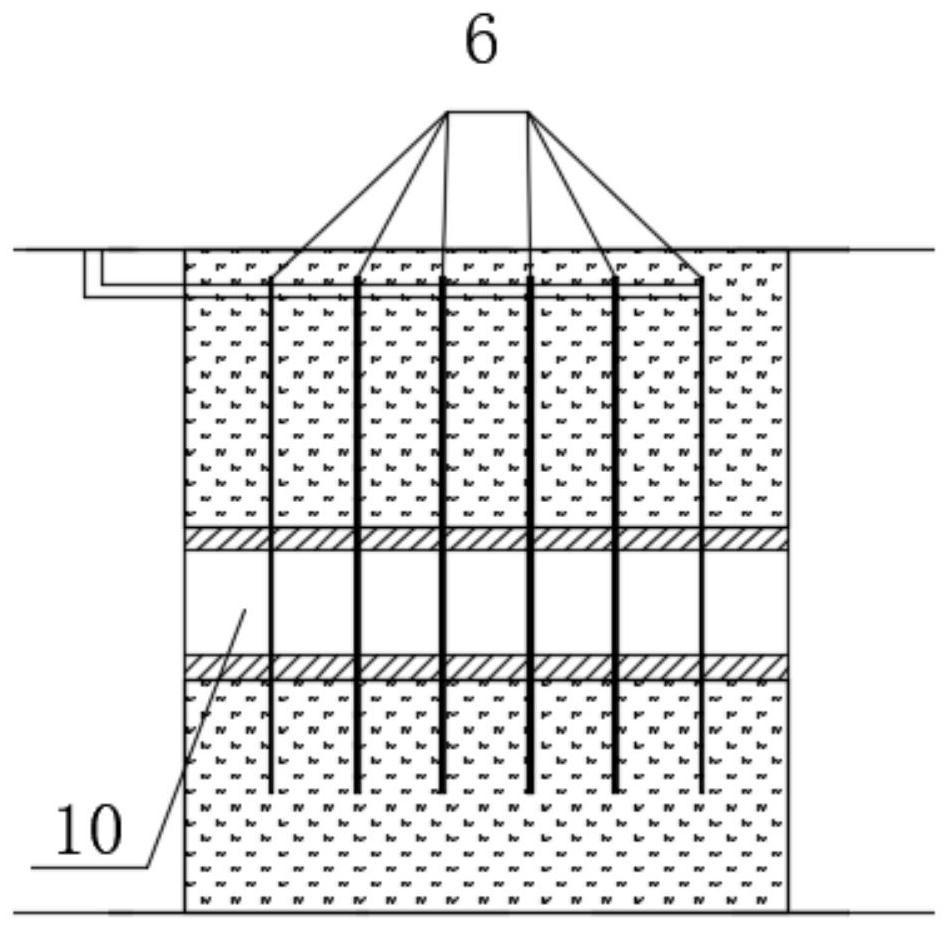

[0032] A kind of monitoring system is applied with several assembled casing pipes in embodiment 1, such as figure 1 and 2 As shown, the monitoring structure includes a number of monitoring points, each monitoring point is provided with a detection hole, and the assembled casing is inserted into the detection hole, and the assembled casing is assembled according to the depth of the hole drilled at the detection point. The axial depth depends on the sinking depth of the sewage pipe at the point to be monitored, and the bottom end of the assembled casing is at least one meter deeper than the bottom of the sewage pipe.

[0033] In this embodiment, monitoring points are arranged on both sides at intervals of 100 meters along the direction of the sewage pipeline, and monitoring points must be arranged at the welded joints of the pipe joints. The plane position of the monitoring point is no more than 0.5 meters away from the sewage pipe, and the depth exceeds the buried depth of the...

Embodiment 3

[0037] A monitoring method, which uses the assembled casing of embodiment 1 and the monitoring system of embodiment 2, comprising the following steps: along the direction of the sewage pipeline, monitoring points are set on both sides of the sewage pipeline; drilling and placement at each monitoring point At least one assembled casing; after connecting the sensor and the counterweight, put them into the assembled casing, and close the top sealing tube of the assembled casing; number the installed monitoring holes, use GNSS to collect the plane and Elevation information, generate drainage facility monitoring system hole layout map, store in the computer terminal for real-time monitoring. Record the liquid level height measured by each sensor as: (h, n), wherein, h is the liquid level height measured by the sensor, and n is the serial number of the sensor; (h, n) is transmitted to the computer terminal, And it corresponds to the position of each monitoring point on the hole layo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com