Cross-flow air cooling rotor and high-speed motor

An air-cooled, high-speed motor technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of uneven cooling and poor cooling effect, and achieve good energy saving effect, enhanced heat dissipation effect, and improved cooling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

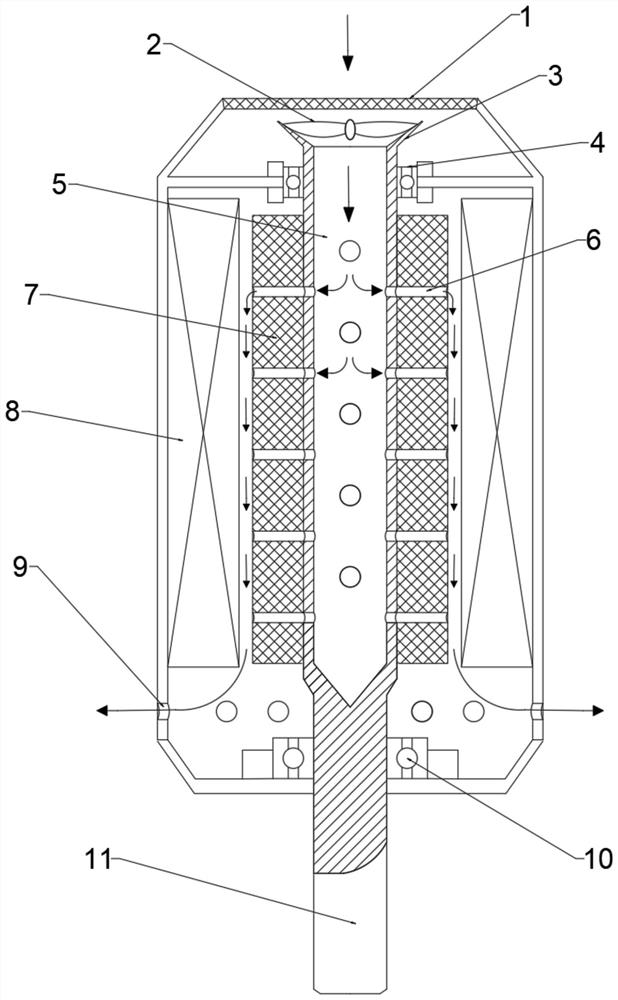

[0038] see figure 1 As shown, this embodiment provides a cross-flow air-cooled rotor, including a hollow shaft 5 with a hollow interior, and a permanent magnet rotor 7 sleeved on the hollow shaft 5. One end of the hollow shaft 5 is open, and the other end is The output shaft 11 of the high-speed motor is fixedly connected, and the permanent magnet rotor 7 is also provided with several cooling centrifuge tubes connected to the inner cavity of the hollow shaft 5 .

[0039] In this embodiment, the cooling air centrifuge tubes 6 are arranged in a staggered axial direction along the hollow shaft 5 . A staggered parallel arrangement is preferred. This setting can make full use of the centrifugal force brought by the rotation to drive the cooling air flow to achieve the cooling effect; the heat dissipation effect is more uniform and local overheating is avoided. The opening position of the hollow shaft 5 is also provided with a compressor turbine 2 , and when the compressor turbine...

Embodiment 2

[0041] Such as figure 1 As shown, the present embodiment provides a high-speed motor with rotor cross-flow air cooling, including a casing, a hollow shaft 5, a permanent magnet rotor and a stator 8. The hollow shaft 5 is hollow inside, and its two ends pass through bearings respectively (that is, corresponding to the front and rear respectively) The end is the front bearing 4 and the rear bearing 10) supported in the housing, and one end of the hollow shaft 5 is open, and the other end is fixedly connected to the output shaft 11 of the high-speed motor. The permanent magnet rotor is sleeved on the hollow shaft 5 and fixed on the hollow shaft 5. The stator 8 on the inside of the casing is installed on the coaxial center line, and the permanent magnet rotor 7 is also provided with a plurality of cooling gas centrifuge tubes 6 that penetrate radially, leaving a gap between the permanent magnet rotor 7 and the stator 8 .

[0042] In this embodiment, the cooling air centrifugal tubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com