Screen sounding structure, front cover plate, rear cover plate and electronic equipment

A technology of screen sound and front cover, which is applied in the field of rear cover and electronic equipment, front cover, and screen sound structure, and can solve the problem of dual MIC noise reduction performance degradation, Echo processing performance degradation, and poor audio and video playback effects, etc. problem, to achieve the effect of full screen sound, simple structure, and normal display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

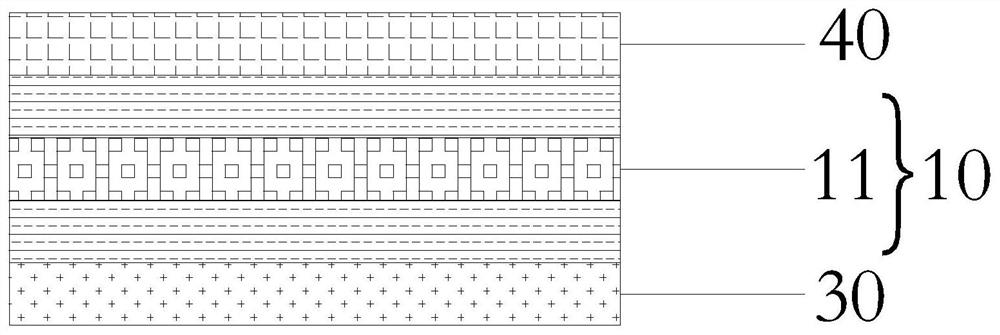

[0031] Such as figure 1 As shown, in order to solve the above problems, this embodiment proposes a screen sound structure, which includes the internal drive circuit of the mobile terminal, and also includes a sequential and stacked front cover support structure 40, ITO piezoelectric film 10 and back cover support Structure 30; conductive lines are formed on both ends of the ITO piezoelectric film 10, and the conductive lines are electrically connected to the internal drive circuit; the ITO piezoelectric film 10 vibrates under the drive of the internal drive circuit, and drives the front cover support structure 40 Or the rear cover support structure 30 resonates and sounds.

[0032] In this embodiment, the ITO piezoelectric film 10 is a film structure, relatively soft, so the front cover support structure 40 or the rear cover support structure 30 mainly provides support for the ITO piezoelectric film 10, and under the premise of ITO vibration , the front cover support structur...

Embodiment 2

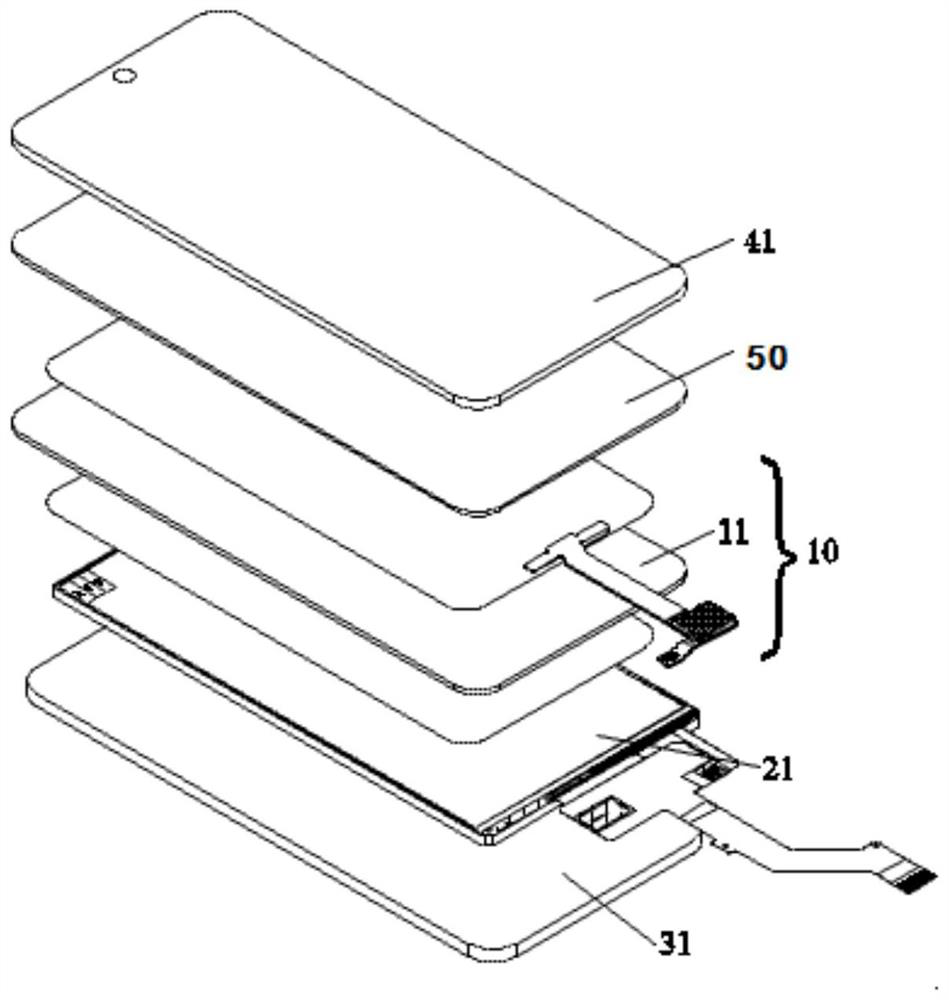

[0036] Such as Figure 2 to Figure 4 As shown, this embodiment proposes a front cover, which includes the internal drive circuit of the mobile terminal, and also includes a front cover support structure 40, an ITO piezoelectric film 10, and a rear cover support structure 30 that are sequentially and stacked; The electrical film 10 is a polyvinylidene fluoride film 11 (hereinafter referred to as PVDF film 11 ) with ITO coating on both sides. The above structure is consistent with that of Embodiment 1, and will be repeated here.

[0037] In this embodiment, the front cover support structure 40 includes a front cover protective glass, and the rear cover support structure 30 includes a complete machine assembly module 30 .

[0038] In this embodiment, the front cover protective glass and the ITO piezoelectric film 10 are bonded by optical glue 50 to ensure the tightness of the bonding between the ITO piezoelectric film 10 and the front cover protective glass, thereby ensuring the...

Embodiment 3

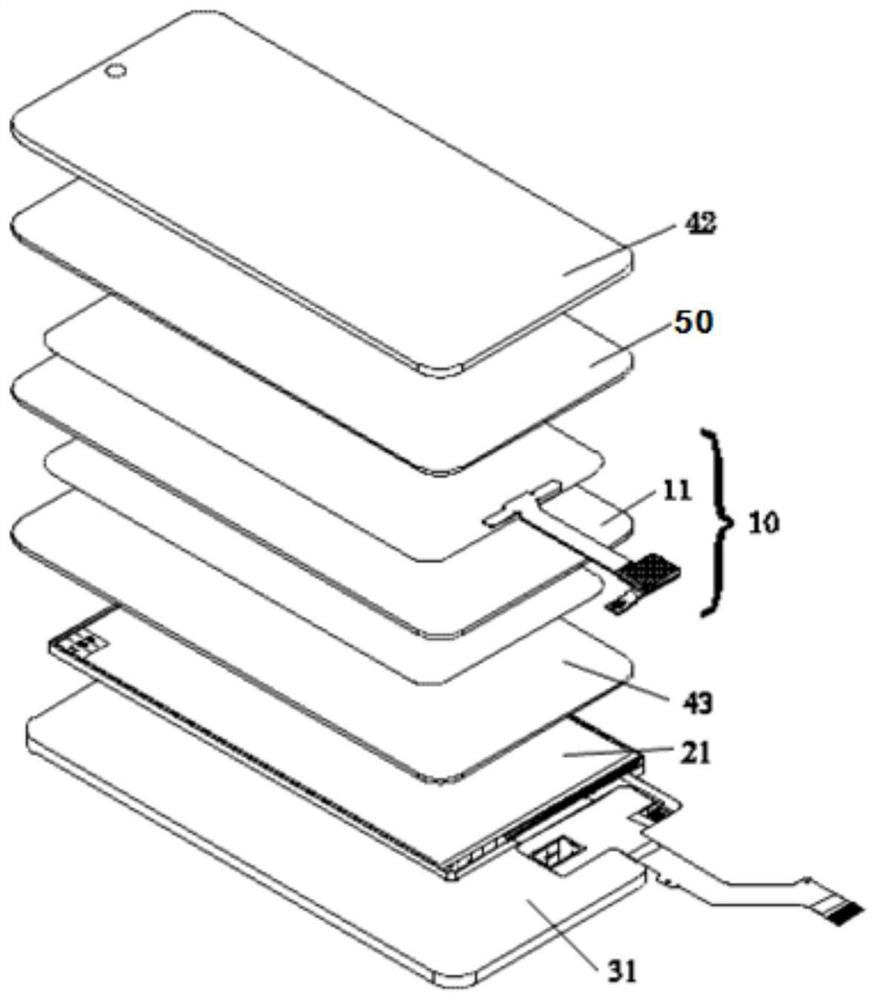

[0043] Such as Figure 5 to Figure 7 As shown, in order to solve the aforementioned problems, this embodiment proposes a rear cover, including an internal drive circuit, a front cover support structure 40, an ITO piezoelectric film 10 and a rear cover support structure 30, and the ITO piezoelectric film 10 is a double For the polyvinylidene fluoride film (hereinafter referred to as PVDF film 11 ) with an ITO coating on its surface, the positional relationship between the above structures is the same as that of Embodiment 1, and will not be repeated here.

[0044] In this embodiment, the front cover support structure 40 is a glass panel, and the rear cover support structure 30 is a rear decorative glass 32 .

[0045] In this embodiment, the ITO piezoelectric film 10 is attached to the rear decorative glass 32 through optical glue 50 . Among them, OCA optical glue 50 is preferably used between the ITO piezoelectric film 10 and the rear decorative glass 32 .

[0046] More speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com