Semiconductor device and producing method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their manufacturing, can solve problems such as large resistance value, poor high-frequency characteristics, and no practical and effective manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

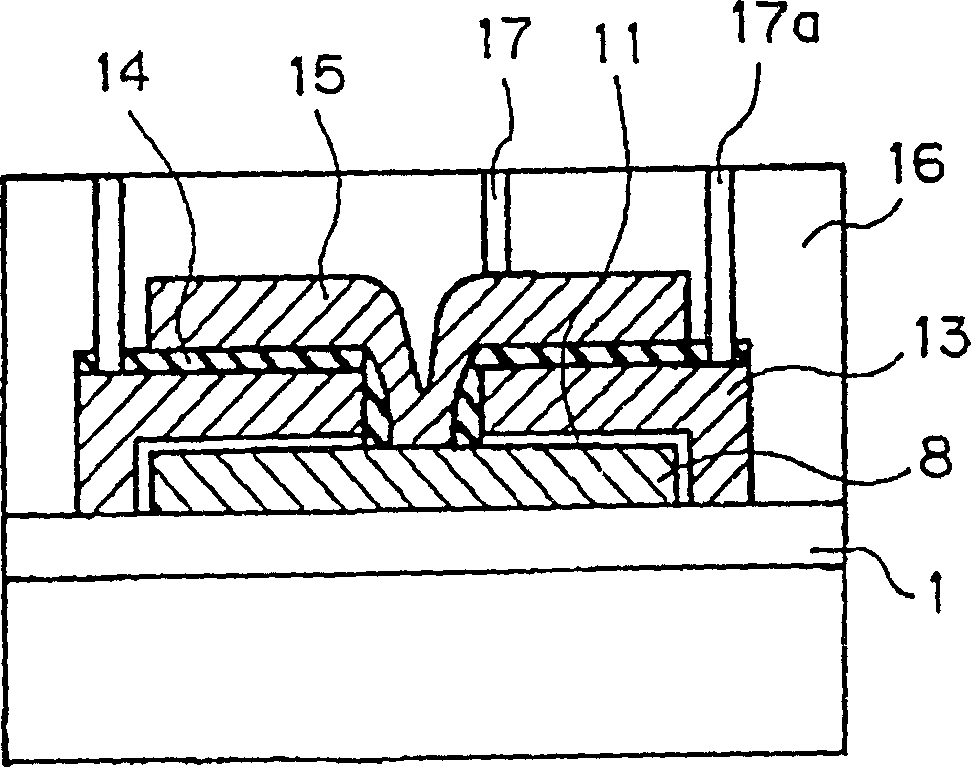

[0085] Referring to the accompanying drawings, the first manufacturing method of the present invention will be described in detail below.

[0086] First, refer to image 3 . On the silicon substrate 30, in the region intended to be the formation region 33 of the bipolar transistor, an n as a collector electrode is formed. + Buried layer 2, p + Buried layer 3. Next, an epitaxial layer 4 having a thickness of about 1 to 2 μm and a resistance of 0.5 to 2 Ω·cm is grown on the surface. Then a local oxidation of silicon (LOCOS) oxide film 1 (field oxide film) is formed with a thickness of 200-400 nm to isolate elements from each other. At this time, a LOCOS oxide film is formed to cover the entire surface of the capacitor formation region 32 . Next, an n well is formed in the p-MOS formation region 34, and next, a p well 5 is formed in the n-MOS formation region 34, thereby completing image 3 manufacturing steps.

[0087] Pass 1~5×10 13 cm -2 Phosphorus implanted with an a...

no. 2 example

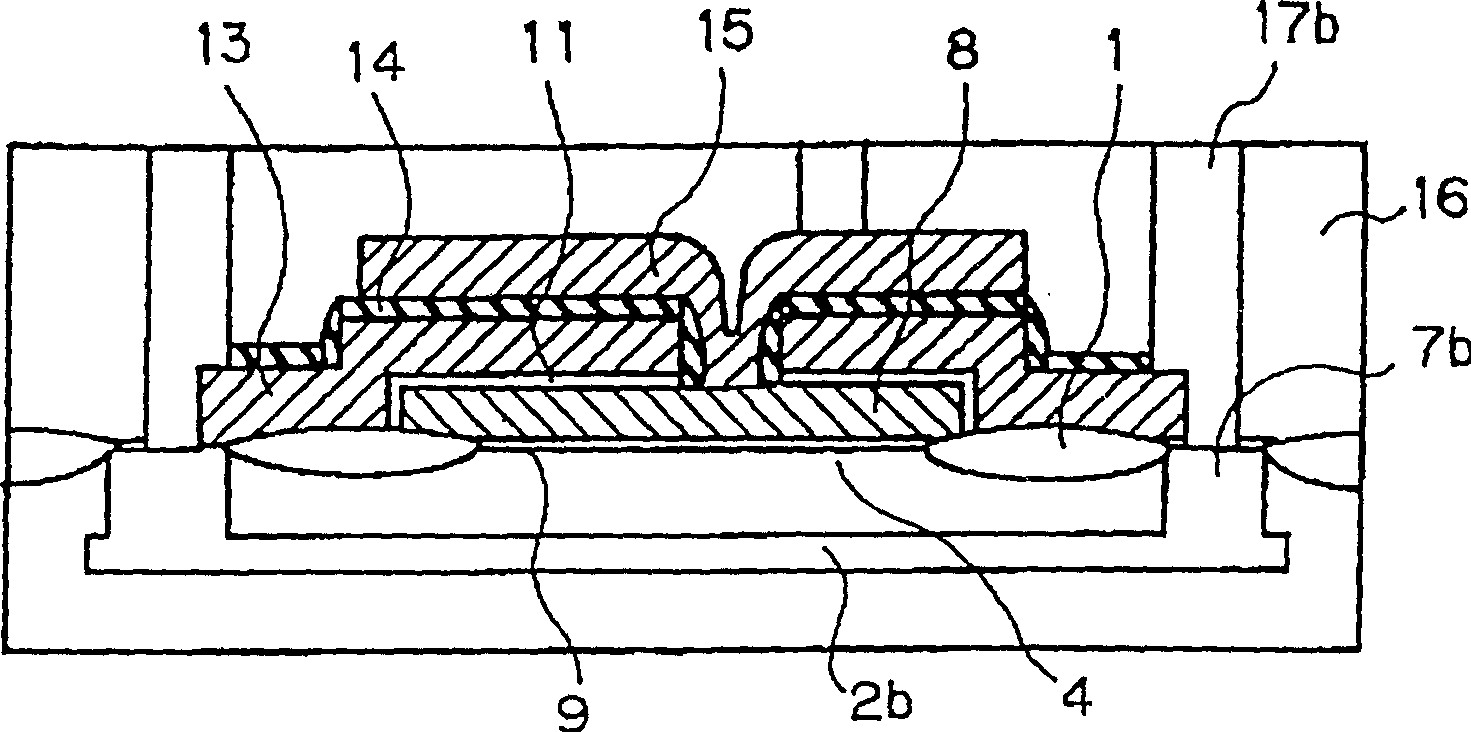

[0099] Referring to the accompanying drawings, the second manufacturing method of the present invention will be described in detail.

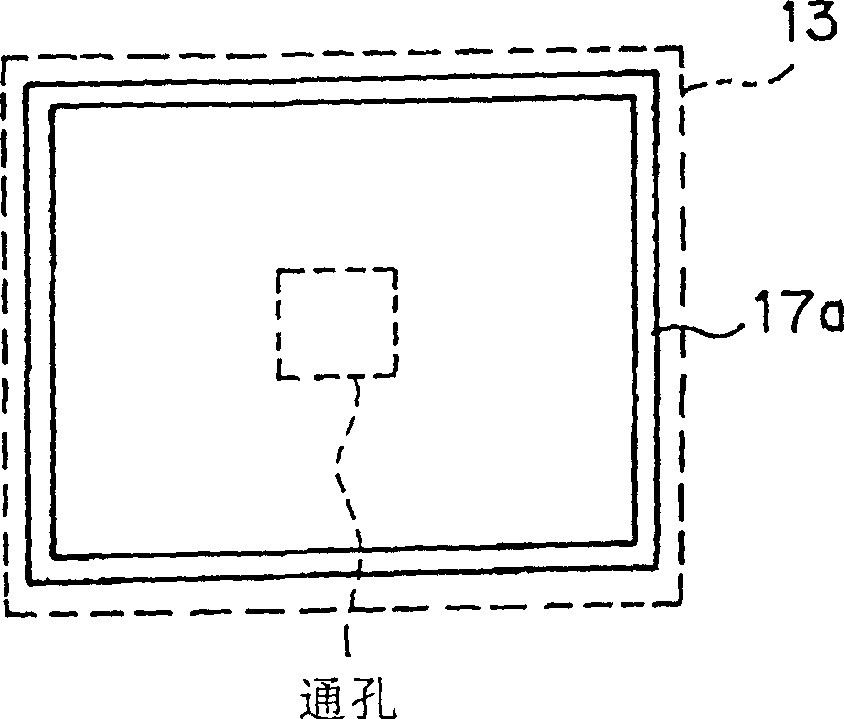

[0100] First, as in the first embodiment, n + buried layers 2 and p + Buried layer 3. After growing epitaxial layer 4 on the surface, LOCOS oxide film 1 (field oxide film) is formed, after which n well 6 and p well 5 are formed by ion implantation. Also, in this example, n + The buried layer 2b is provided under the capacitor forming region 32 as Figure 11 shown. the n + The buried layer 2b functions as the fourth electrode of the capacitor. Considering the LOCOS oxide film 1 in the capacitor formation region 32, it can be set as Figure 11 In the label 1b, set aside the central part as a window. Or in the capacitor forming region, the LOCOS oxide film represented by numeral 1b is not formed at all.

[0101] Next, to form n + The contact of the buried layer 2 is formed under similar conditions to the first embodiment n + Collector g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com