Self-settling desorption type oil-containing industrial waste gas treatment equipment

A technology for industrial waste gas and treatment equipment, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve respiratory diseases, difficult to clean, easy to adhere and other problems, to extend the friction area, improve the effect and efficiency of blocking , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

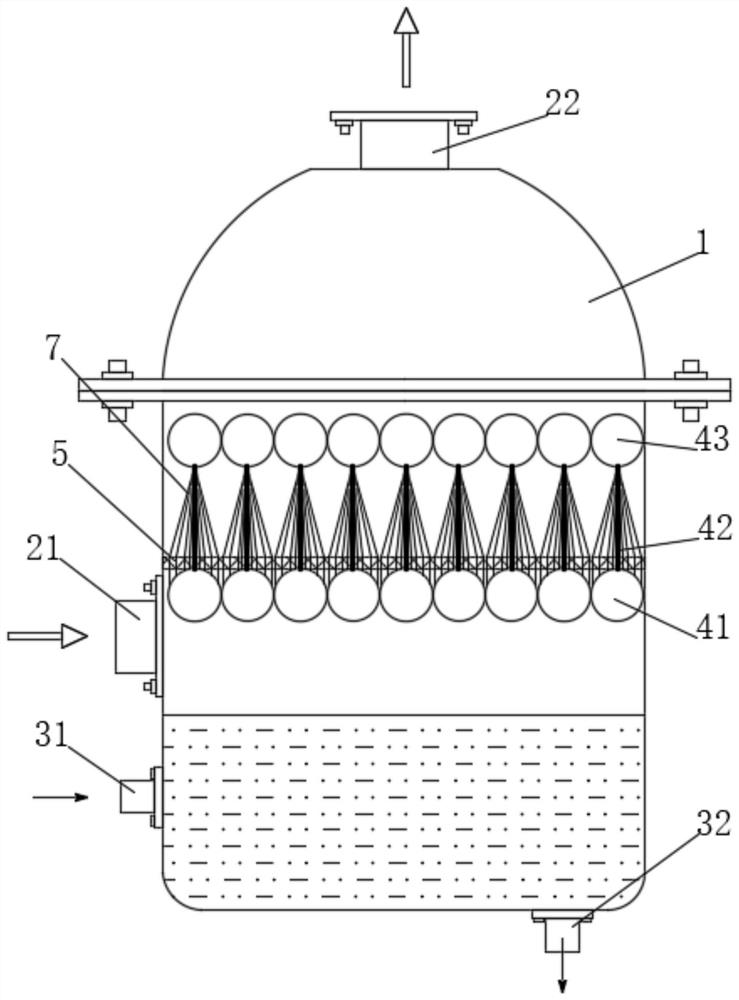

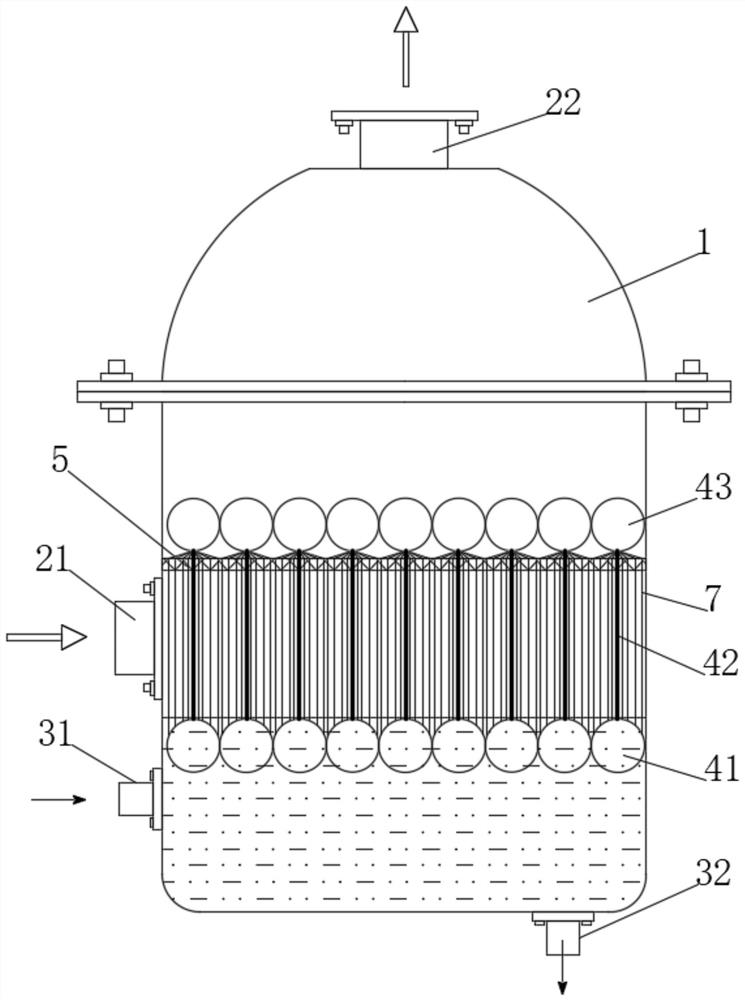

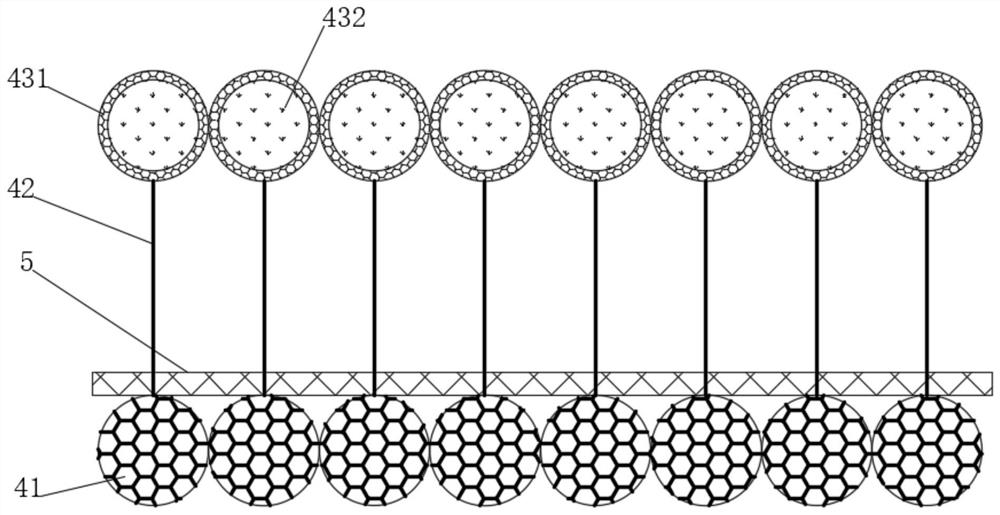

[0040] see figure 1 , the solid arrows in the figure indicate the flow direction of the oil decomposing agent, and the hollow arrows indicate the flow direction of the waste gas. A self-settling and desorption type oily industrial waste gas treatment equipment includes a device body 1, and the left and upper ends of the device body 1 are respectively fixedly connected with inlet The air port 21 and the air outlet 22, the air inlet 21 and the air outlet 22 are all communicated with the device body 1, and the left end of the device body 1 and the lower right end of the device body 1 are respectively fixedly connected with a liquid inlet 31 and a liquid outlet 32 with valves , the liquid inlet 31 is located below the air inlet 21, and both the liquid inlet 31 and the liquid outlet 32 are in communication with the device body 1, the inner bottom of the device body 1 is filled with an oil decomposing agent through the liquid inlet 31, and the inner wall of the device body 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com