Radial drilling machine for high-precision stamping die processing

A technology for stamping dies and radial drilling machines, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of waste of coolant, inability to re-use, increase in mold processing costs, etc., to reduce waste and prolong Service life, the effect of reducing excessive waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

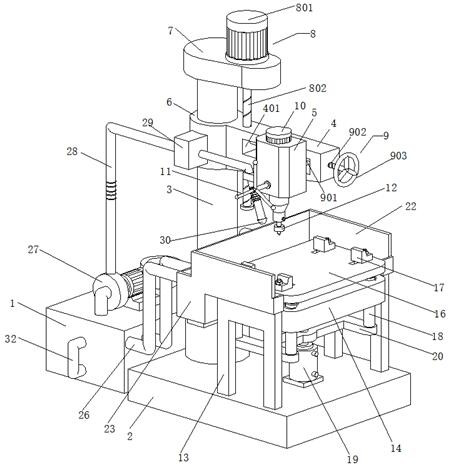

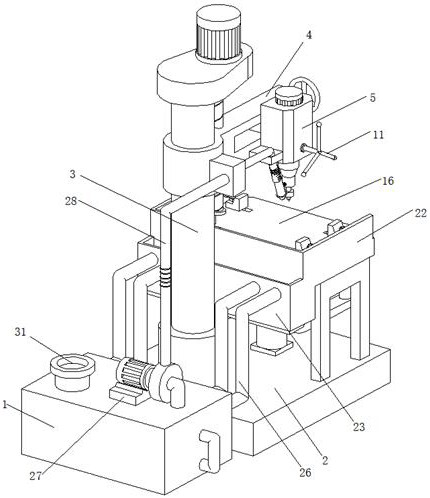

[0037] Embodiment 1 introduces a radial drilling machine for high-precision stamping die processing. The main body includes a drilling machine body and a liquid storage tank 1, and the liquid storage tank 1 is arranged on the rear side of the drilling machine body. Wherein the drilling machine body comprises a base 2, a column 3, a rocker arm 4 and a drilling box 5, and the column 3 is fixedly welded on the upper surface of the base 1, and the rear end of the rocker arm 4 is provided with a sliding cylinder 6 which is socketed with the column 3, And the upper end of column 3 is rotated to be provided with a top block 7, and the rocker lifting mechanism 8 that is connected with rocking arm 4 is provided with on top block 7. Specifically, its rocker arm lifting mechanism 8 includes a rotating motor 801 and a first lead screw 802, and the rotating motor 801 can be a low-speed motor whose signal is YDS112. The rotating motor 801 is fixed on the front end of the upper surface of th...

Embodiment 2

[0044] Embodiment 2 is a further improvement made on the basis of embodiment 1, and another kind of better replacement to permanent magnet, specifically described as follows:

[0045] The overall part of embodiment 2 is the same as the embodiment, and the same part will not be described again. The difference is that at first the permanent magnet 25 on the bottom wall of the cooling liquid recovery tank 23 is replaced by an electromagnet group composed of a plurality of electromagnets. And the electromagnet group is arranged on the lower surface of the coolant recovery tank 23 . By replacing the permanent magnet 25 with an electromagnet group, when the iron filings on the bottom wall of the coolant recovery tank 23 need to be cleaned after the machining is completed, it is only necessary to disconnect the electromagnet switch, and then the internal iron filings can be cleaned conveniently.

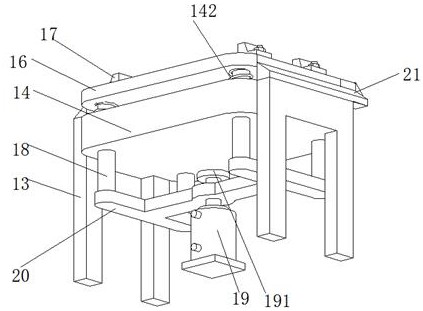

[0046] In addition, a guide slope 161 is also provided on the rear side of the mold pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com