A cement batching system

A batching system and cement clinker technology, applied in mixer accessories, transportation and packaging, packaging, etc., can solve problems affecting cement production quality, blockage of hopper outlet, inaccurate proportioning, etc., to save manufacturing costs, reduce Stable and smooth effect of dust and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

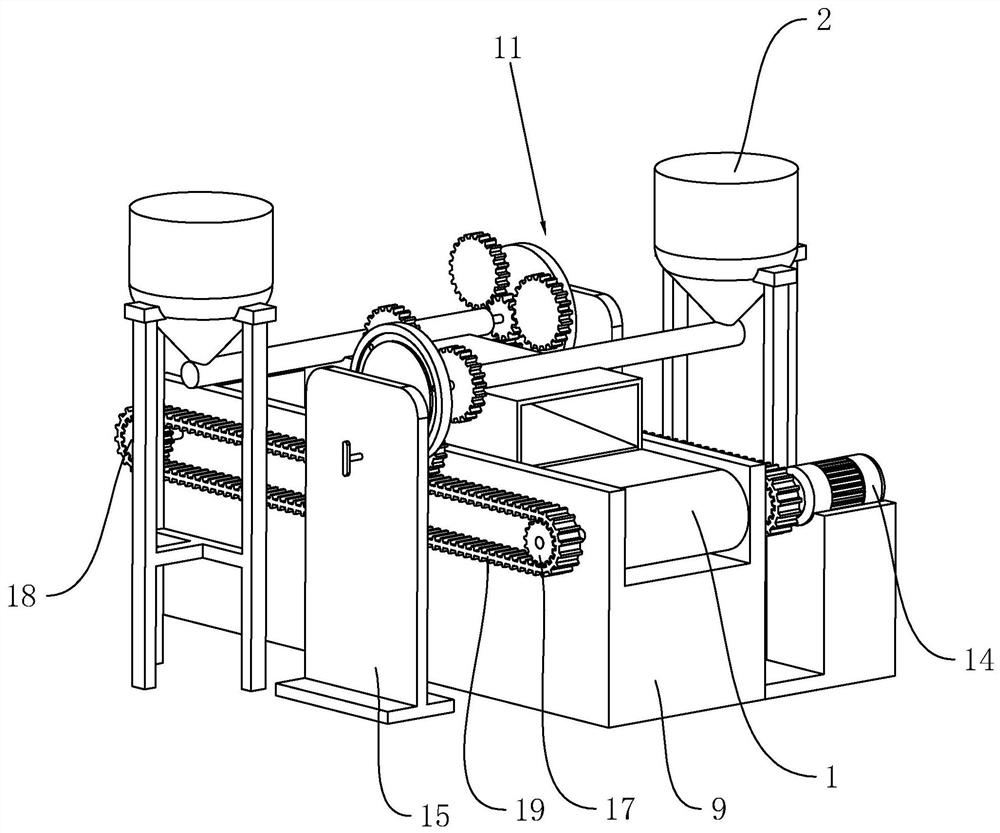

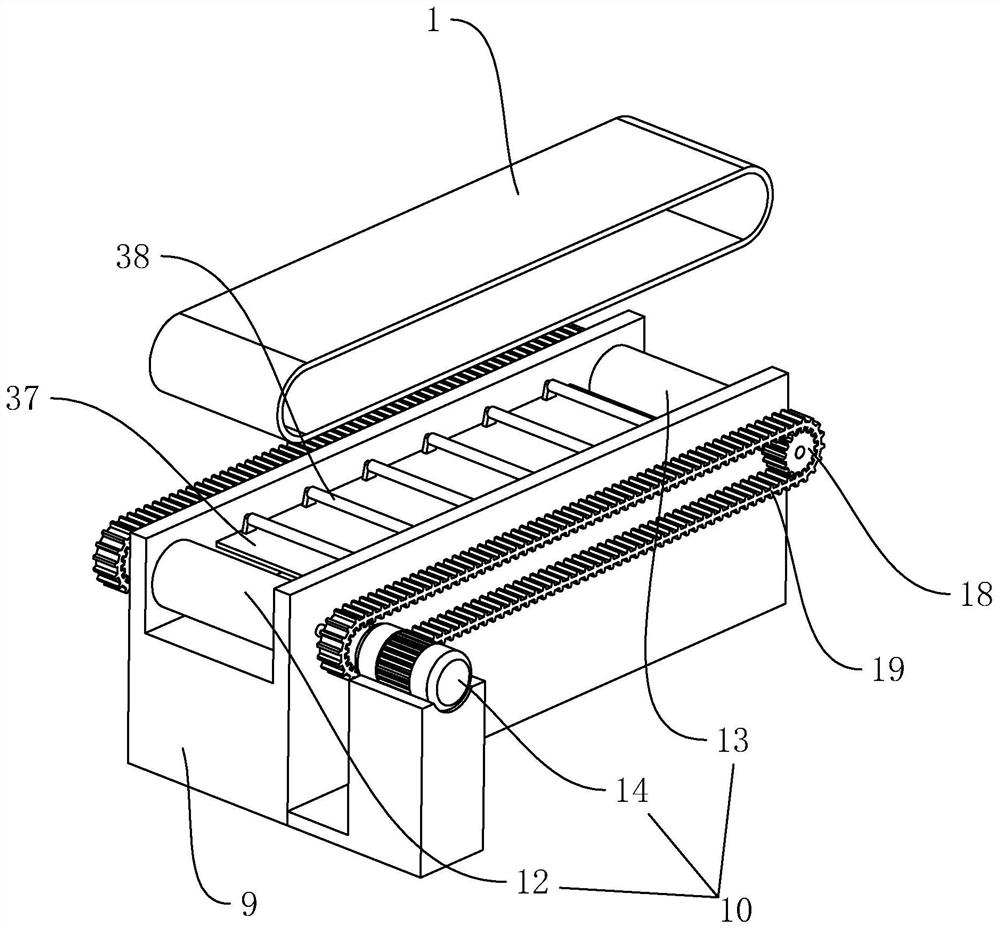

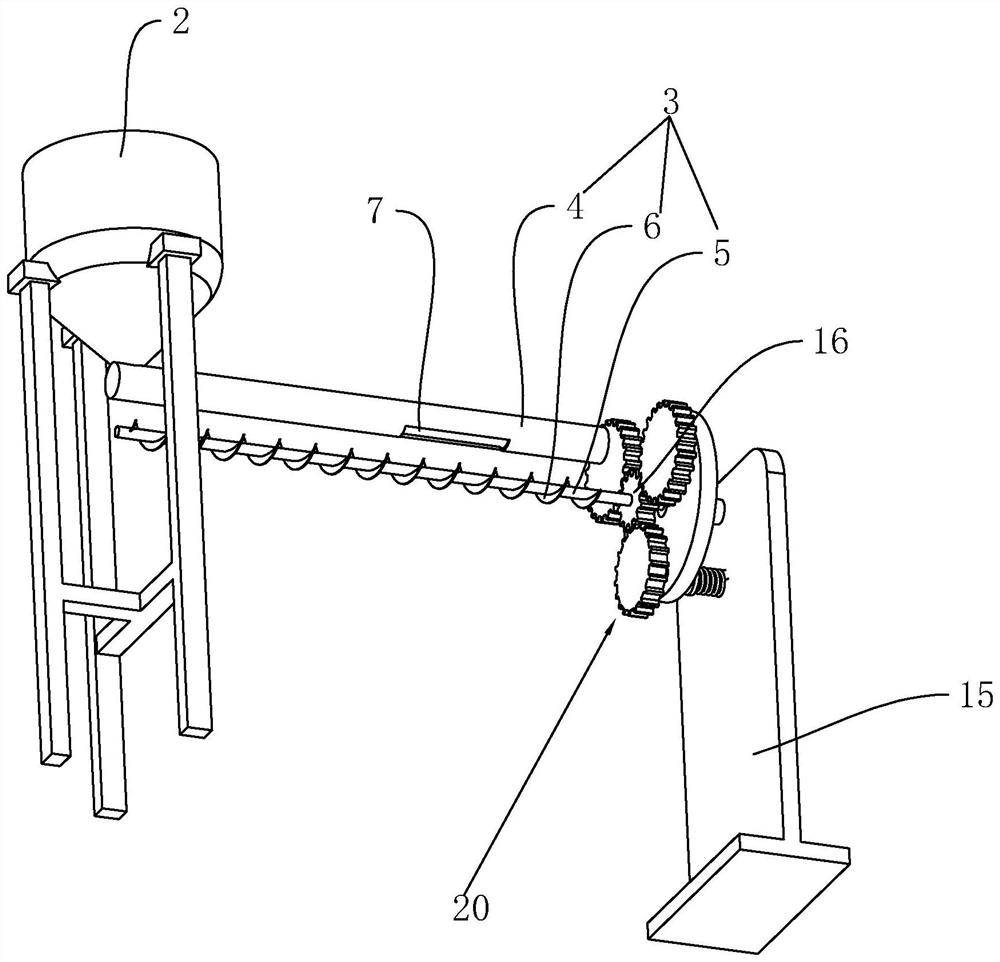

[0032] Such as figure 1 As shown, it is a cement batching system disclosed by the present invention, which includes a conveyor belt 1. A base 9 is arranged below the conveyor belt 1. The cross section of the base 9 is U-shaped. The conveyor belt 1 is located between the inner walls on both sides of the upper end of the base 9. The base Both sides of 9 are also provided with hoppers 2, and the two hoppers 2 are all located at the initial end of the conveyor belt 1, one hopper 2 is used for installing blast furnace slag, and the other hopper 2 is used for installing gypsum powder. When carrying out proportioning and mixing, First place the cement clinker on the initial end of the conveyor belt 1, and the hoppers 2 on both sides of the base 9 also supply materials to the conveyor belt 1 at the same time. Fine grinding can form a complete cement.

[0033] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com