Manufacturing method of high-temperature large embossed porcelain plate

A production method and embossing technology, applied to clay products, applications, household appliances, etc., can solve the problems that the shrinkage rate of embossed products cannot be controlled under processing conditions, the flatness requirements of assembly operations cannot be guaranteed, and embossed products do not have large-scale specifications, etc. Achieve realistic three-dimensional effect, enhance toughness and avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

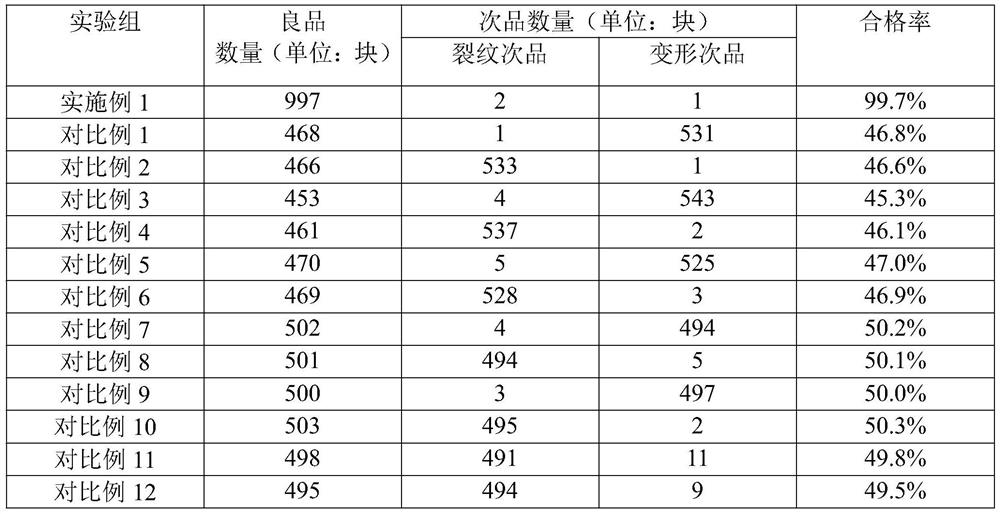

Examples

Embodiment 1

[0045] A method for manufacturing a large high-temperature embossed porcelain plate, comprising the following steps:

[0046] The first step, making relief mud and glaze, specifically: the relief mud consists of 30-40% of large ball clay, 20%-25% of kaolin, 5%-20% of potassium feldspar, quartz 5%-20% and 10%-25% of porcelain powder are made of mud; the glaze includes 42%-60% of feldspar, 10%-15% of talc, 20%-30% of quartz and Clay 5%-8%;

[0047] The second step is to create relief works and turn them into relief plaster molds or relief silicone molds;

[0048] The 3rd step, make relief gypsum mold or relief silica gel mold into the working model of relief works, described working model comprises upper mold and lower mold;

[0049] Step 4: Put the relief mud in the working mold and adjust the gap between the upper mold and the lower mold to 3cm, and use the grouting equipment to inject high pressure into the gap along four different directions of the working mold Glaze, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com