Spraying coating and preparation method and spraying method thereof

A paint and dry material technology, which is applied in the field of spray paint and its preparation, can solve problems that are easy to endanger people's health, affect the leveling of paint products, affect the use of paint, etc., and achieve good spray effect, low toxicity, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

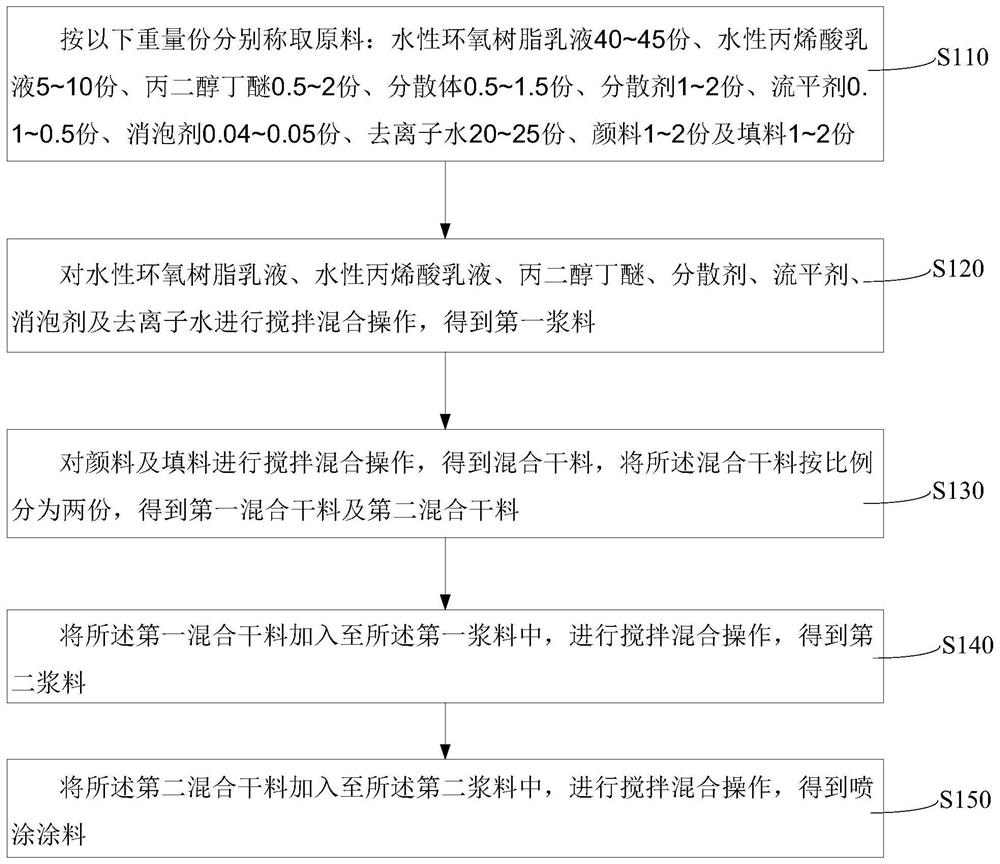

[0033] One embodiment, a spray paint, comprising the following raw materials in parts by mass: 40-45 parts of water-based epoxy resin emulsion, 5-10 parts of water-based acrylic emulsion, 0.5-2 parts of propylene glycol butyl ether, 0.5-1.5 parts of dispersion, 1-2 parts of dispersant, 0.1-0.5 parts of leveling agent, 0.04-0.05 parts of defoamer, 20-25 parts of deionized water, 1-2 parts of pigment and 1-2 parts of filler.

[0034] It should be noted that deionized water is used as the diluent, and deionized water refers to pure water after removing impurities in the form of ions, which can avoid the introduction of impurities and help improve the quality of finished spray coatings. By adding water-based acrylic emulsion, it can Cooperate with water-based epoxy resin emulsion to get easy to spray, good adhesion and good toughness spray coating, which can be sprayed faster and better, and then by adding propylene glycol butyl ether, it is beneficial to improve the coalescence pe...

Embodiment 1

[0062] Weigh 40 parts of water-based epoxy resin emulsion, 5 parts of water-based acrylic emulsion, 0.5 part of propylene glycol butyl ether, 0.5 part of graphene, 1 part of polyethylene glycol 200, 0.1 part of fluorocarbon surfactant, 0.04 part of polyether modified Silicone defoamer, 20 parts of deionized water, 1 part of pigment and 1 part of filler.

[0063] Stir and mix water-based epoxy resin emulsion, water-based acrylic emulsion, propylene glycol butyl ether, graphene, polyethylene glycol 200, fluorocarbon surfactant, polyether modified silicone defoamer and deionized water to obtain first slurry.

[0064] The pigment and the filler are stirred and mixed to obtain a mixed dry material, and the mixed dry material is divided into two parts according to the ratio of 60%:40%, to obtain a first mixed dry material and a second mixed dry material.

[0065] The first mixed dry material is added to the first slurry, and a stirring and mixing operation is performed to obtain a ...

Embodiment 2

[0070] Weigh 42.5 parts of water-based epoxy resin emulsion, 7.5 parts of water-based acrylic emulsion, 1.25 parts of propylene glycol butyl ether, 1 part of graphene, 1.5 parts of polyethylene glycol 200, 0.3 parts of fluorocarbon surfactant, and 0.045 parts of polyether modified Silicone defoamer, 22.5 parts of deionized water, 1.5 parts of pigment and 1.5 parts of filler.

[0071] Stir and mix water-based epoxy resin emulsion, water-based acrylic emulsion, propylene glycol butyl ether, graphene, polyethylene glycol 200, fluorocarbon surfactant, polyether modified silicone defoamer and deionized water to obtain first slurry.

[0072] The pigment and the filler are stirred and mixed to obtain a mixed dry material, and the mixed dry material is divided into two parts according to the ratio of 62.5%:37.5%, to obtain a first mixed dry material and a second mixed dry material.

[0073] The first mixed dry material is added to the first slurry, and a stirring and mixing operation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com