Heat treatment process for anti-rust and anti-corrosion steel

A technology for anti-rust, anti-corrosion, and steel, which is applied in the coating process of metal materials, devices for coating liquid on the surface, and coatings, etc. problems, achieve good structural stability and structural strength, increase cooling rate, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

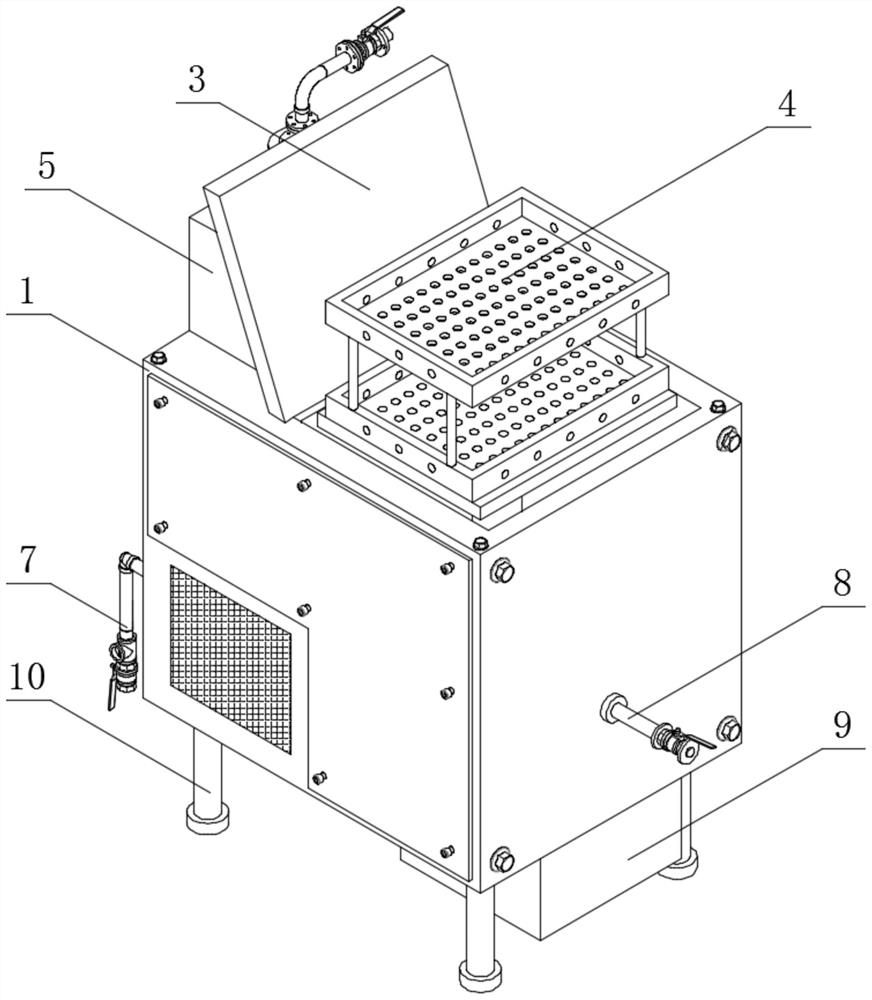

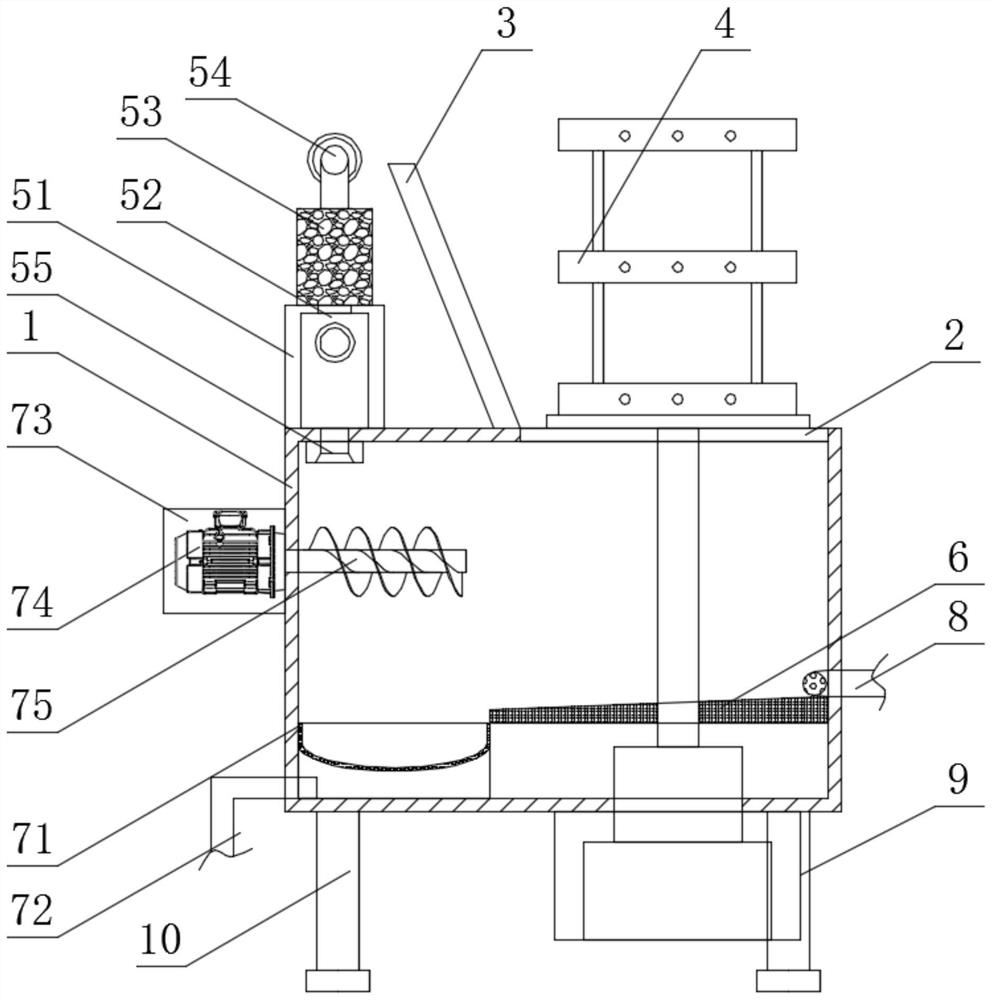

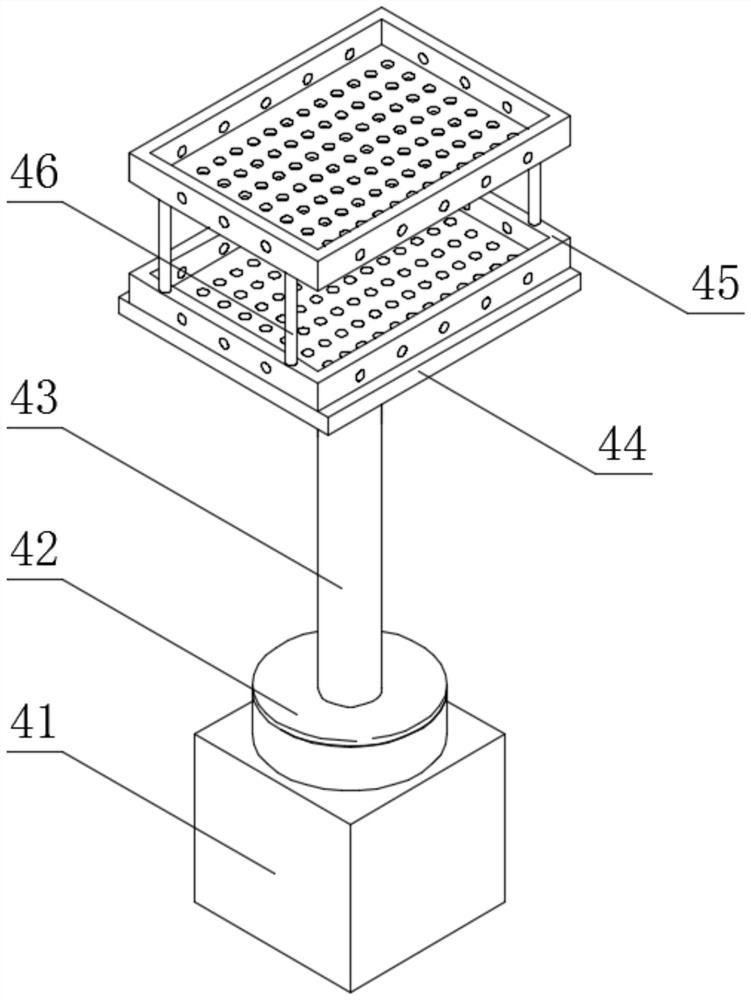

[0029] Such as Figure 1-3 Shown, a kind of heat treatment process of anti-rust and anti-corrosion steel, comprises the following steps:

[0030] S1: Select the appropriate steel and clean the steel. Steel wire should be used to wipe the rust spots for hard steel; steel with low hardness should be wiped with cotton cloth; after the surface of the steel is cleaned quickly, the steel should be tempered deal with;

[0031] S2: Pass the steel through a box-type resistance furnace for quenching treatment, select a suitable que...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com