Preparation technology of high strength rare earth aluminum alloy

A preparation process and technology of aluminum alloy, applied in the field of aluminum alloy, can solve the problems of hindering dislocation movement and limited improvement, and achieve the effect of prolonging the service life, optimizing the grain structure, and broadening the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

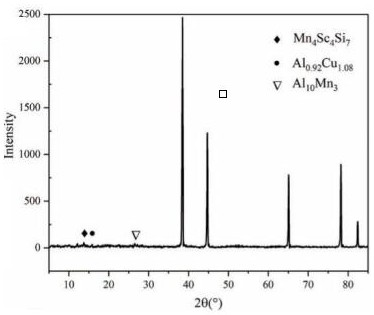

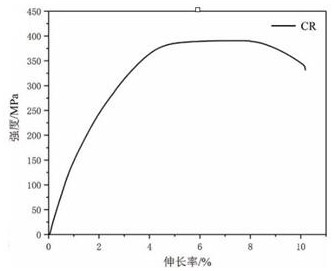

Image

Examples

Embodiment 1

[0028] The object of the present invention is to provide a preparation process of a high-strength rare earth aluminum alloy, which is characterized in that, in terms of mass percentage, the composition of main elements used for alloying is as follows. Magnesium (Mg) is 0.7% to 0.9%, silicon (Si) is 0.4% to 0.6%, scandium (Sc) is 0.2% to 0.3%, zirconium (Zr) is 0.15% to 0.2%, and the rest is Al. Specific steps are as follows:

[0029] A Casting: According to the composition of the alloy design, an alloy ingot with a mass of 2kg is melted. In order to avoid the influence of oxides and impurities on the surface of the material on the quality of the alloy, all materials are cleaned with NaOH solution, and then dried to remove the contained water. The prepared aluminum alloy raw materials are melted in a vacuum melting furnace. The casting process is as follows: the aluminum block is melted at a high temperature in the vacuum melting furnace, and the melting temperature is 700°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com