Preparation method of liquid-state base film high in biomass content

A high-capacity, biomass technology, applied in the fields of botanical equipment and methods, plant protection, plant protection cover, etc., can solve the problems of a large number of manual operations and consumption of large energy, and achieve the effect of improving particle structure and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

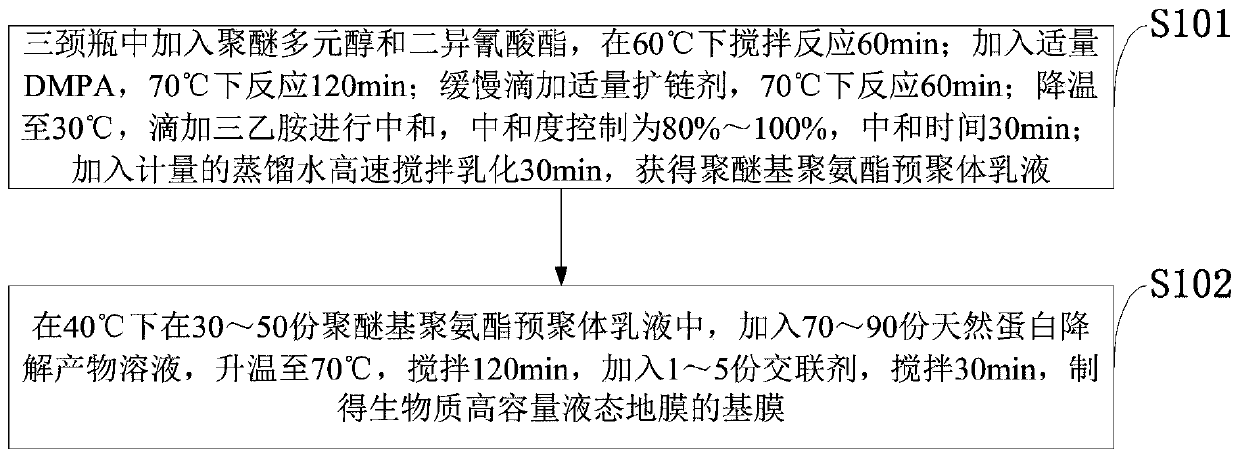

[0022] Such as figure 1 As shown, the preparation method of the biomass high-capacity liquid basement membrane provided by the embodiment of the present invention comprises the following steps:

[0023] S101: Add polyether polyol and diisocyanate to the reaction kettle, stir and react at 60°C for 60 minutes; add appropriate amount of DMPA, react at 70°C for 120 minutes; slowly add appropriate amount of chain extender, react at 70°C for 60 minutes; cool down to 30°C, Add triethylamine dropwise for neutralization, the neutralization degree is controlled at 80% to 100%, and the neutralization time is 30 minutes; add metered distilled water and stir and emulsify at high speed for 30 minutes to obtain a polyether-based polyurethane prepolymer emulsion;

[0024] S102: Add 70-90 parts of natural protein degradation product solution to 30-50 parts of polyether-based polyurethane prepolymer emulsion at 40°C, raise the temperature to 70°C, stir for 120 minutes, add 1-5 parts of cross-li...

Embodiment 1

[0033] The preparation method of the biomass high-capacity liquid basement membrane provided by the embodiment of the present invention comprises the following steps:

[0034] 1) Add a certain amount of polypropylene glycol and hexamethylene diisocyanate into the reaction kettle, stir and react at 60°C for 60 minutes; add an appropriate amount of DMPA, and react for 120 minutes at 70°C; slowly add an appropriate amount of 1,4-butanediol dropwise, React at 70°C for 60 minutes; cool down to 30°C, drop triethylamine for neutralization, control the degree of neutralization to 100%, and neutralize for 30 minutes; add metered distilled water and stir and emulsify at high speed for 30 minutes to obtain a water-based polyurethane emulsion (solid content ~30%).

[0035] 2) Add 30 parts of polyurethane emulsion at 40°C, add 70 parts of collagen degradation products and 500g of water, stir to fully dissolve the protein degradation products, raise the temperature to 70°C, continue stirrin...

Embodiment 2

[0038] The preparation method of the biomass high-capacity liquid basement membrane provided by the embodiment of the present invention comprises the following steps:

[0039] 1) Add a certain amount of polyethylene glycol and toluene diisocyanate into the reaction kettle, stir and react at 60°C for 60 minutes; then add an appropriate amount of DMPA, and react for 120 minutes at 70°C; slowly add appropriate amount of ethylene glycol dropwise, and react for 60 minutes at 70°C Cool down to 30°C, add triethylamine dropwise for neutralization, control the degree of neutralization to 80%, and control the neutralization time to 30 minutes; add metered distilled water and stir and emulsify at high speed for 30 minutes to obtain a water-based polyurethane emulsion (solid content ~ 30% ).

[0040] 2) Add 40 parts of polyurethane emulsion at 40°C, add 80 parts of collagen degradation product and 600 parts, stir with water to fully dissolve the protein degradation product, raise the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com