Ceramic steam cavity radiator

A vapor cavity and radiator technology, which is applied to electric solid state devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problems of increasing the difficulty of heat dissipation, the limitations of the use of devices, the long heat transfer path, and the large thermal resistance, etc. To achieve the effect of shortening the heat transfer path, short heat transfer path, and strong heat spreading ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

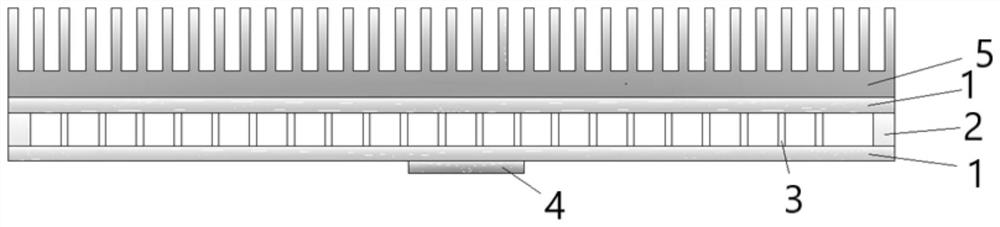

[0024] Such as figure 1 As shown, the ceramic steam chamber radiator of the present invention includes two substrates 1 and side walls 2, one of the two substrates 1 is used as the top wall of the housing, and the other is used as the bottom wall of the housing;

[0025] The two base plates 1 and the side wall 2 are integrally welded to form a shell structure containing a closed cavity, and the inside of the shell is filled with liquid working fluid;

[0026] The substrate 1 is made of ceramic material;

[0027] The side wall 2 is made of metal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com