Solid electrolyte with self-supporting structure, preparation method and application

A technology of solid electrolyte and self-supporting structure, which is applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of being thick and brittle, unable to meet the requirements of forming thin flexible films, and poor interface contact, etc. The process method is simple, the effect of ensuring ionic conductivity and uniform product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

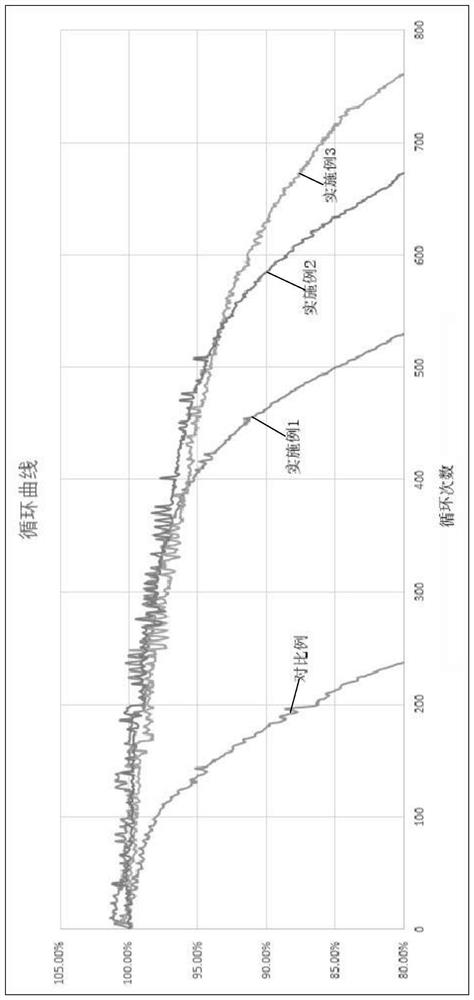

Embodiment 1

[0040] This embodiment discloses a solid electrolyte with a self-supporting structure, its preparation method and application. The preparation method of the solid electrolyte in this embodiment includes the following steps:

[0041] Step 1, preparing active ceramic powder-binder flexible body;

[0042] According to active ceramic powder Li 7 La 3 Zr 2 o 12 The stoichiometric ratio of raw materials LiOH, La(OH) 3 , ZrO 2 , add 10% more LiOH to make up for the lithium loss during the synthesis.

[0043] The raw material was ball milled for 12 h, then heated at 950° C. for 14 h.

[0044] After cooling, ball mill for 12h.

[0045] Get active ceramic powder Li 7 La 3 Zr 2 o 12 .

[0046] The active ceramic powder and the binder PVDF were mixed according to a mass ratio of 95:5, and ball milled for 60 minutes to obtain the active ceramic powder-binder flexible body;

[0047] Step 2. Place the 80-mesh nylon mesh in the middle of the active ceramic powder-binder flexible ...

Embodiment 2

[0054] This embodiment discloses a solid electrolyte with a self-supporting structure, its preparation method and application. The preparation method of the solid electrolyte in this embodiment includes the following steps:

[0055] Step 1, preparing active ceramic powder-binder flexible body;

[0056] According to active ceramic powder Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 The stoichiometric ratio of raw materials LiOH, La(OH) 3 , ZrO 2 、 Ta 2 o 5 , add 10% more LiOH to make up for the lithium loss during the synthesis.

[0057] The raw material was ball milled for 12 hours, and then heated at 900° C. for 12 hours.

[0058] After cooling, ball mill for 12h.

[0059] Get active ceramic powder Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 .

[0060] The above-mentioned active ceramic powder and binder PTFE were mixed according to the mass ratio of 94:6, and ball milled for 40 minutes to obtain the active ceramic powder-binder flexible body.

[0061] Step 2: Place a 100-mesh ny...

Embodiment 3

[0068] This embodiment discloses a solid electrolyte with a self-supporting structure, its preparation method and application. The preparation method of the solid electrolyte in this embodiment includes the following steps:

[0069] Step 1, preparing active ceramic powder-binder flexible body;

[0070] According to active ceramic powder Li 0.35 La 0.55 TiO 3 The stoichiometric ratio of raw materials LiOH, La(OH) 3 、TiO 2 , add 10% more LiOH to make up for the lithium loss during the synthesis.

[0071] The raw material was ball milled for 12 h, then heated at 1050° C. for 14 h.

[0072] After cooling, ball mill for 12h.

[0073] Get active ceramic powder Li 0.35 La 0.55 TiO 3 .

[0074] The above active ceramic powder and binder PVDF were mixed according to a mass ratio of 97:3, and ball milled for 40 minutes to obtain an active ceramic powder-binder flexible body.

[0075] Step 2: Place a 100-mesh nylon mesh in the middle of the active ceramic powder-binder flexibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com