Raw material cleaning equipment for cosmetic production

A technology for cleaning equipment and cosmetics, which is applied in the field of raw material cleaning equipment for cosmetics production. It can solve the problems of incomplete washing of sundries and stains, poor cleaning effect, and easy damage to plants, so as to facilitate collection and subsequent use, and facilitate Recycling and reuse, the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

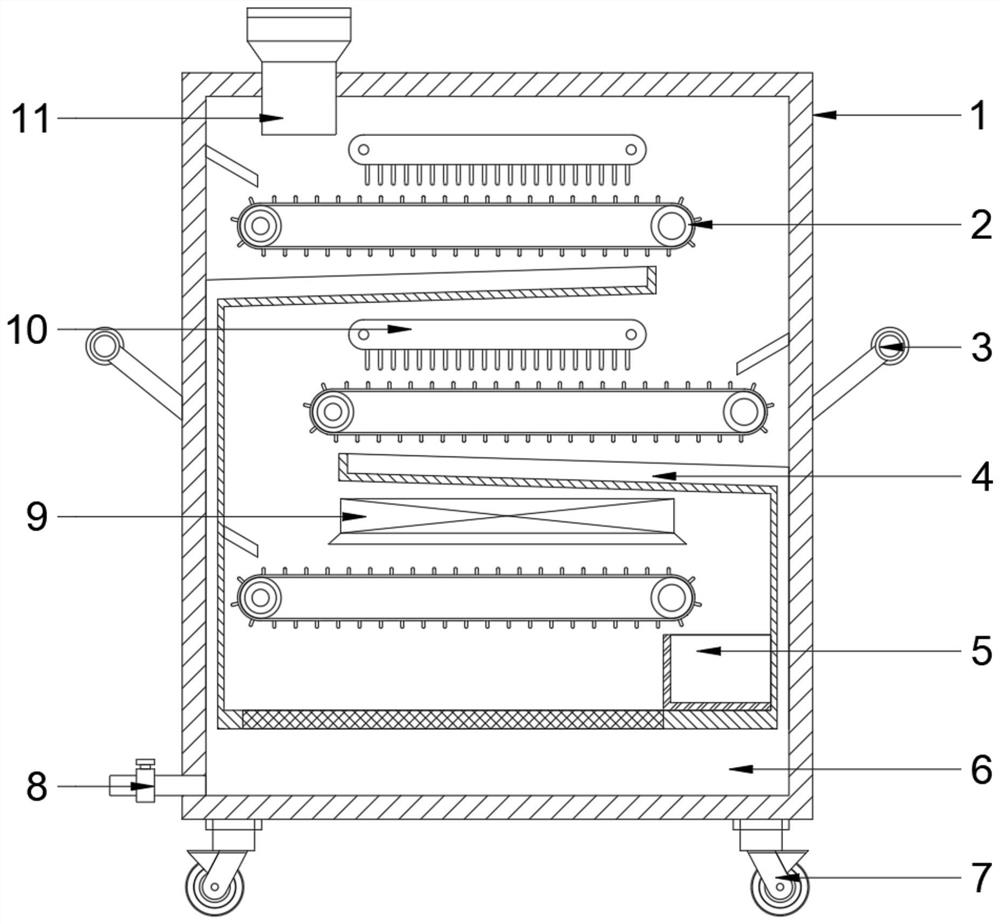

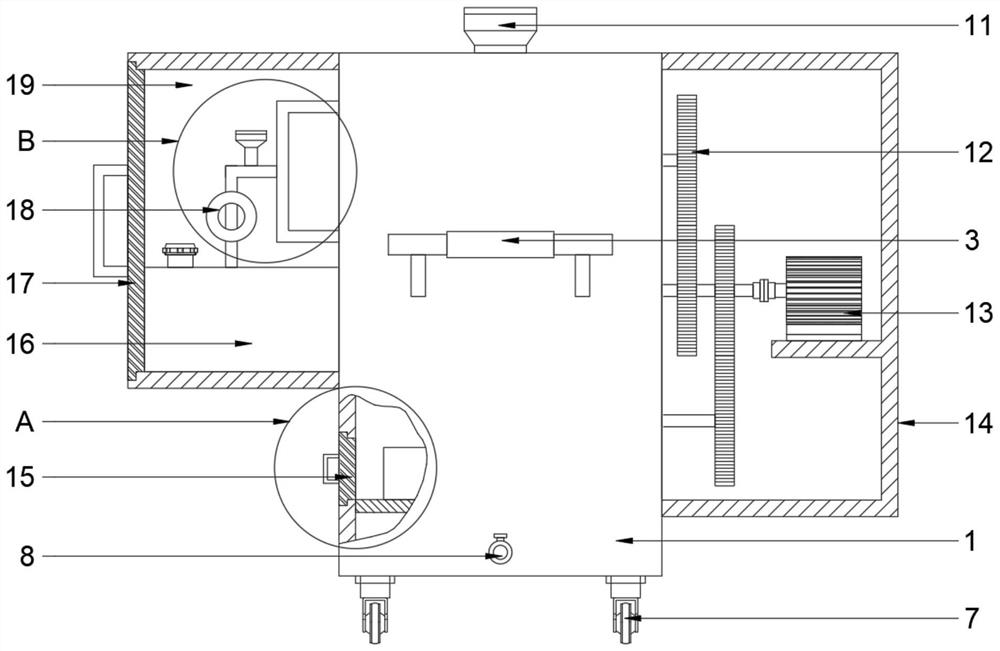

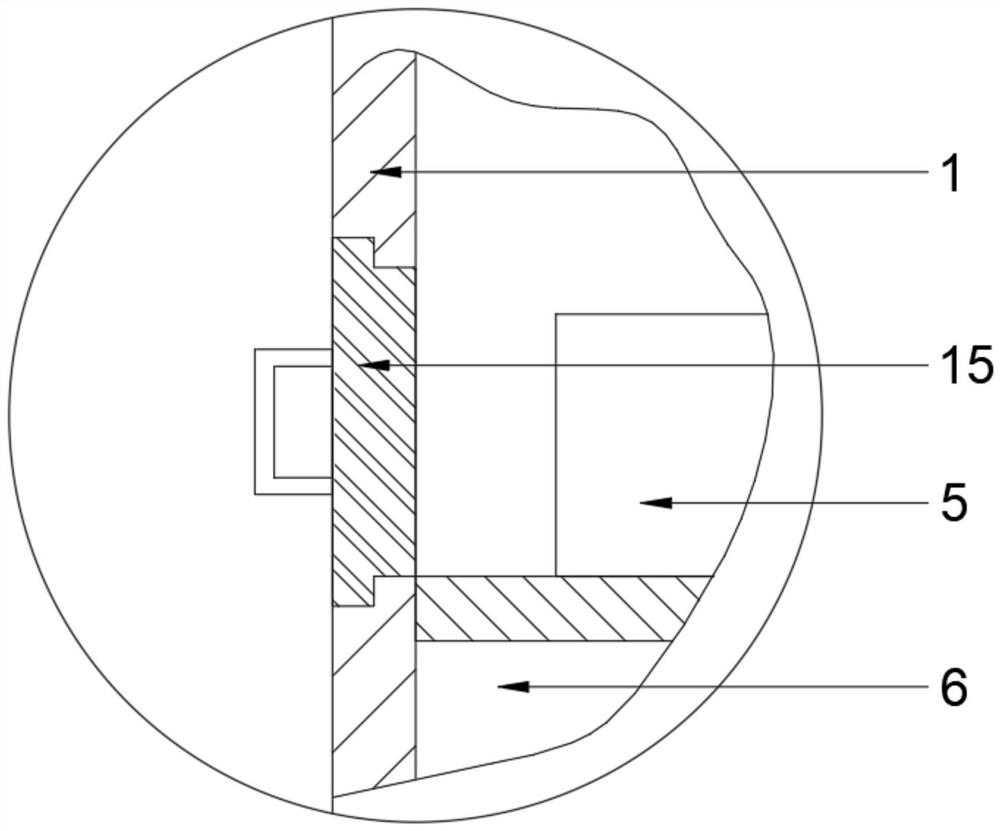

[0029] see Figure 1-7 , in an embodiment of the present invention, a raw material cleaning equipment for cosmetic production includes a cleaning box 1, a conveyor belt 2 and a cleaning assembly arranged inside the cleaning box 1, and the conveyor belt 2 includes a first conveyor belt, a second conveyor belt and a third conveyor belt. Conveyor belts are overlapped and arranged inside the cleaning box 1 along the vertical direction, and the first conveyor belt, the second conveyor belt and the third conveyor belt are respectively connected to the side wall of the cleaning box 1 in rotation and the feed end and the discharge end of the second conveyor belt are respectively connected to the cleaning box 1. The discharge end of the first conveyor belt corresponds to the feed end of the third conveyor belt; the cleaning assembly includes a brush plate 10, a water storage tank 16 and a water storage chamber 19, and the water storage chamber 19 is fixedly installed on the outer wall o...

Embodiment 2

[0039] see figure 1 , in the embodiment of the present invention, a raw material cleaning device for cosmetic production, in order to enhance the practicability of the device and facilitate the subsequent dehydration of the cleaned materials, on the basis of embodiment 1, the inside of the cleaning box 1 is also set A hot air blower 9 is arranged, and the hot air blower 9 is fixedly installed above the third conveyor belt, and the hot air blower 9 blows air to the materials on the third conveyer belt to help the materials dehydrate, which is convenient for collection and subsequent use.

[0040] The working principle of the present invention is:

[0041] When working, push the cleaning handrail 3, move the device to the material cleaning place through the walking wheel 7, fix the walking wheel 7 through the brake disc; open the feeding door, and deliver the material to the inside of the cleaning box 1 through the feeding hopper 11 And fall on the first conveyor belt, start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com