A method for synchronously improving the density and elongation of powder metallurgy materials

A powder metallurgy and synchronous lifting technology, applied in the field of powder metallurgy preparation, can solve the problems of poor performance, only 5%-6%, low density of sintered aluminum alloy, etc., achieve short pressurization time, low equipment requirements, The effect of applying little pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This invention is mainly accomplished through the following steps

[0052] step one

[0053] Weigh 7g of 2024 aluminum alloy atomized alloy powder (appearance is nearly spherical, particle size Dv50=63μm, see Table 1 for composition), and put it into the inner diameter In the pressing mold, the inner wall of the mold is coated with zinc stearate. After the powder loading is completed, uniaxial pressing is carried out, the pressing pressure is 400 MPa, and the holding time is 3 s; the obtained compact has a diameter of 40 mm and a thickness of 2 mm.

[0054] Table 1 Chemical composition of 2024 atomized alloy powder (mass ratio wt.%)

[0055]

[0056] step two

[0057] Assemble the aluminum alloy compact obtained in step 1 into a high-strength graphite mold whose inner wall is sprayed with boron nitride, and then put them together into a vacuum hot-pressing furnace cavity for vacuuming, with a vacuum degree of ≤10 -3 Pa.

[0058] step three

[0059] When the vacu...

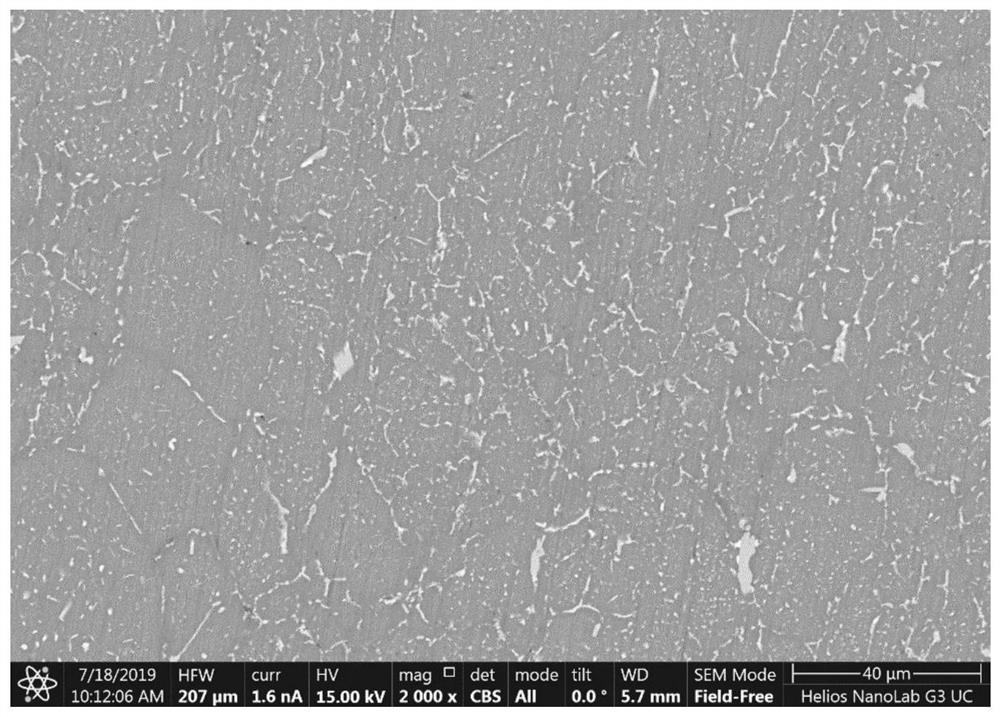

example 1

[0060] The sintered aluminum alloy obtained in Example 1 has a relative density of 99.3%, a main alloy element concentration of Cu: 3.3%, Mg: 1.2%, an average tensile strength of 233.8 MPa, and an average elongation of 9.2%.

Embodiment 2

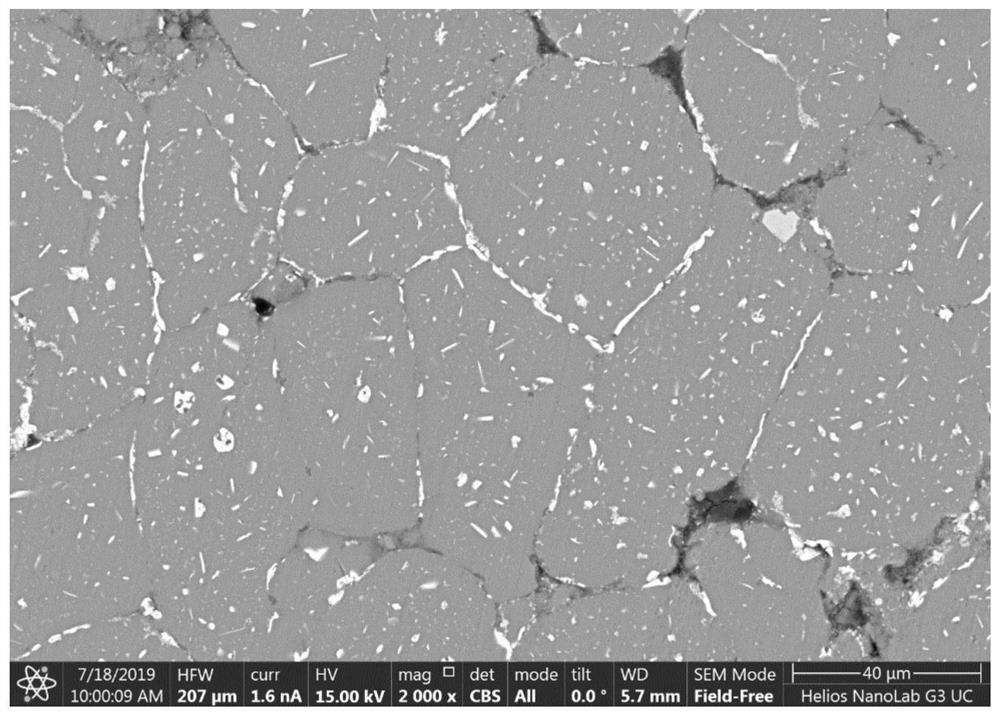

[0062] Step one to step two are consistent with embodiment 1; The difference is:

[0063] step three

[0064] When the vacuum degree of the furnace reaches the standard of step 2, the temperature starts to rise. In the first stage, the temperature is raised from room temperature to 500°C at a rate of 10°C / min, kept for 30 minutes, and a pressure of 15MPa is applied at the same time. Keep the pressure head tight against the body, continue to heat up to 580°C at 5°C / min, and keep warm for 2 hours; after the second stage is completed, cool down to room temperature at 10°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com