Deep hole drilling and boring machine variable-position cutter supporting module

A technology of deep hole drilling and boring machine and support module, which is applied in the direction of boring/drilling, drilling/drilling equipment, support, etc. rust function, no tool cleaning function, etc., to achieve good fixing stability, easy installation and fixing work, and improve tool utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

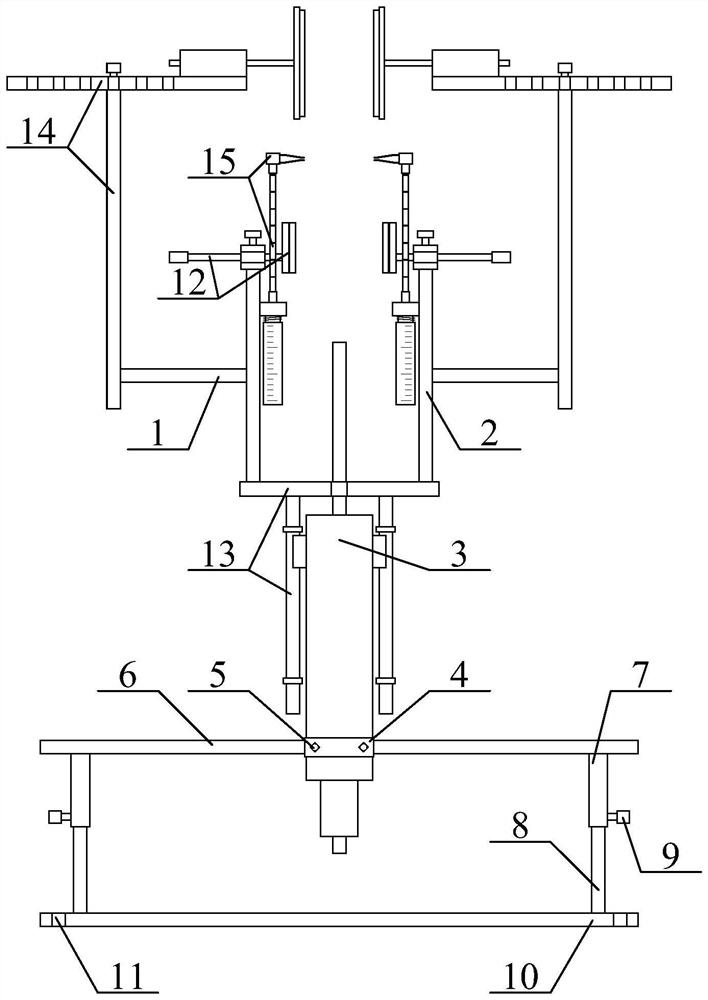

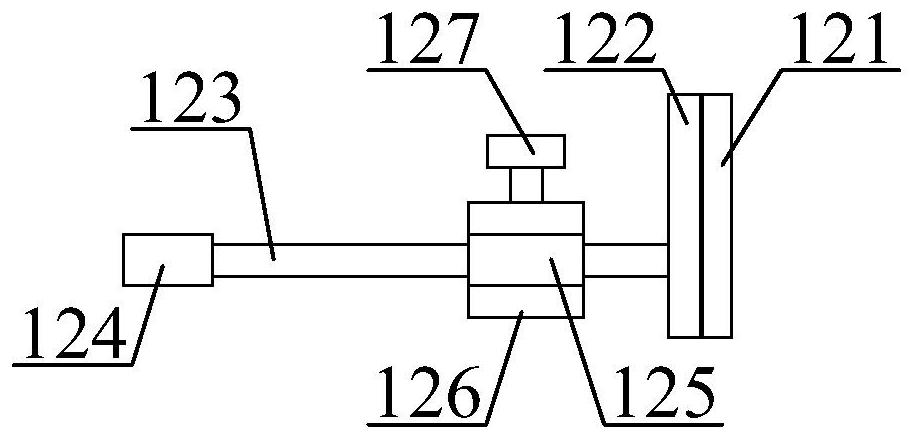

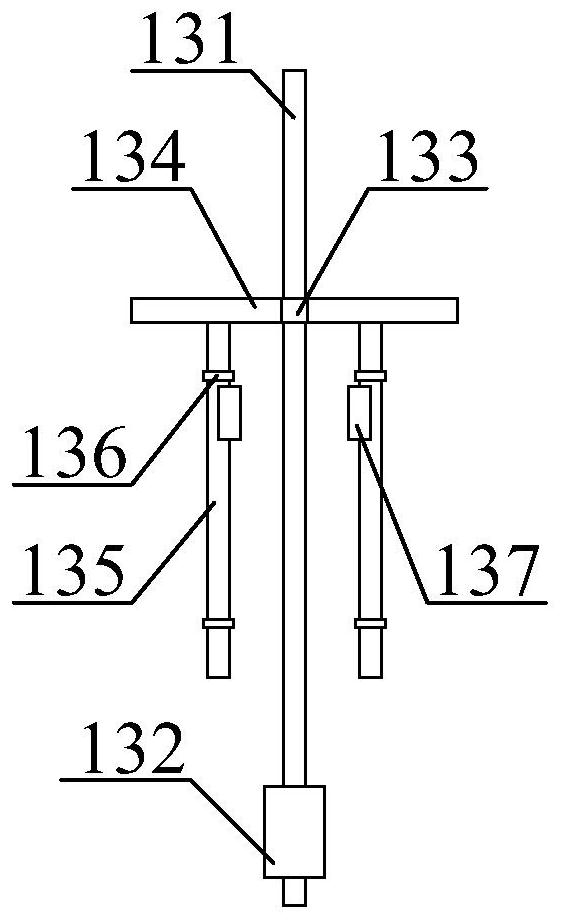

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a variable position tool support module for a deep hole drilling and boring machine includes a connecting seat 1, a support stand 2, a hollow frame 3, a support sleeve 4, lag bolts 5, a beam 6, an adjustment tube 7, and a support rod 8. Adjusting bolt 9, mounting seat 10, mounting hole 11, adjustable tool support clamp structure 12, adjustable sliding rail structure 13, adjustable tool cleaning wheel structure 14 and tool antirust surface oil spray tank structure 15. The horizontal inner end of the connection seat 1 is bolted to the outer middle part of the support stand 2; the longitudinal lower part of the hollow frame 3 is plugged into the support sleeve 4 and fastened by lag bolts 5 Connection arrangement; the left and right ends of the support sleeve 4 are connected with crossbeams 6 by horizontal bolts; the four corners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com