Multi-thermoplastic shape memory polymer 4D printing method

A memory polymer, thermoplastic technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve problems such as structural deformation recovery, achieve recovery of organ function and rehabilitation, broad application prospects, and achieve personalized customization the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] First, two materials, MM4520 and MM5520 from SMP Technologies, Japan, were selected, and their phase transition temperatures were 45°C and 55°C respectively, and the two materials were put into a vacuum drying oven for 3 to 4 hours to obtain dried MM4520 and MM5520 particles;

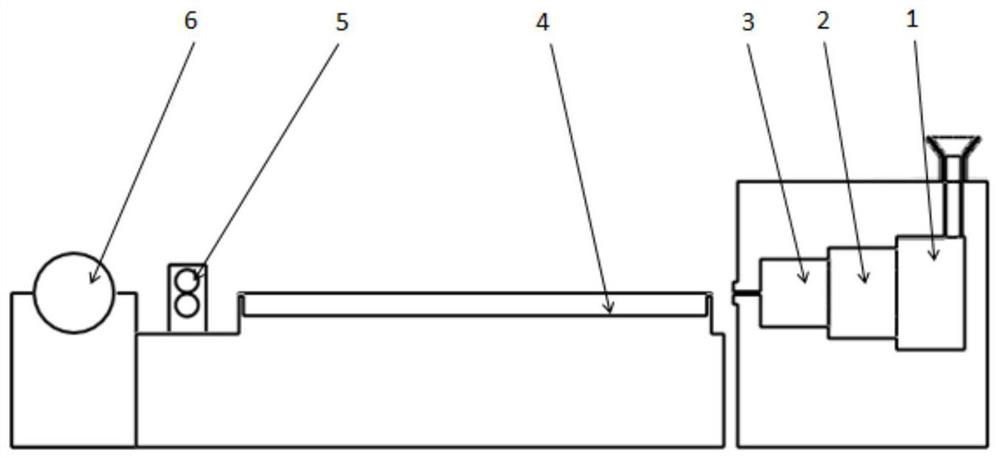

[0063] see figure 1 , respectively put MM4520 and MM5520 particles into a commercial wire drawing machine, set the corresponding preheating temperature zone 1 to 160-170°C, heating temperature zone 2 to 180-190°C, die opening temperature zone 3 to 185-195°C, and the traction mechanism The speed of 5 is 20-60 r / min, the screw speed of wire-receiving mechanism 6 is 100-250 r / min, and the MM4520 and MM5520 particles are respectively preheated, heated and melted, screw extruded, drawn and cooled, and wire-retracted to obtain MM4520 and MM5520 filaments available for fused deposition printing.

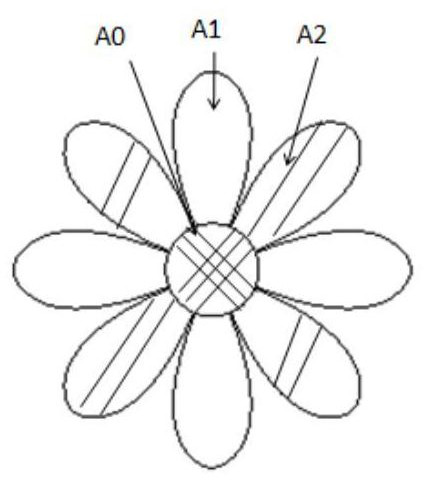

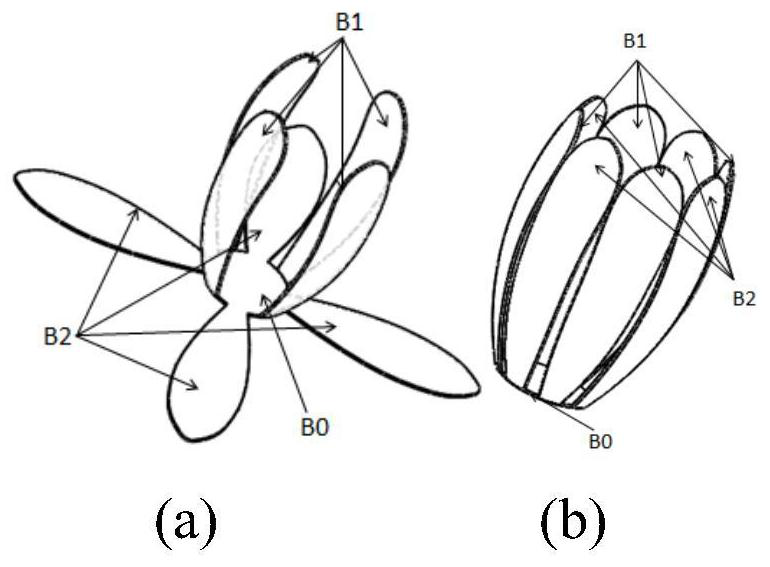

[0064] see figure 2 , use 3D CAD design software to design the structure in the figure from bottom to to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com