A kind of composite concrete admixture and its preparation method and use

A concrete admixture and composite technology, which is applied in the field of cement products and concrete, can solve the problems of construction quality defects, waste, waste concrete, etc., and achieve good economic benefits, reduced solid content, and short setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 6 parts of polycarboxylate superplasticizer and 8 parts of slow-release polycarboxylate superplasticizer according to the proportion, mix them evenly, add water to dilute at a ratio of 1:5, and then add 3 parts of sodium gluconate, 0.5 parts of sucrose, 0.5 parts of sodium hexametaphosphate, mixed and stirred evenly, the temperature of the solution during the preparation process does not exceed 35°C, and finally forms a composite concrete admixture, the dosage is 0.95% of the total amount of cementitious materials, and the water-binder ratio is 0.43. out the concrete.

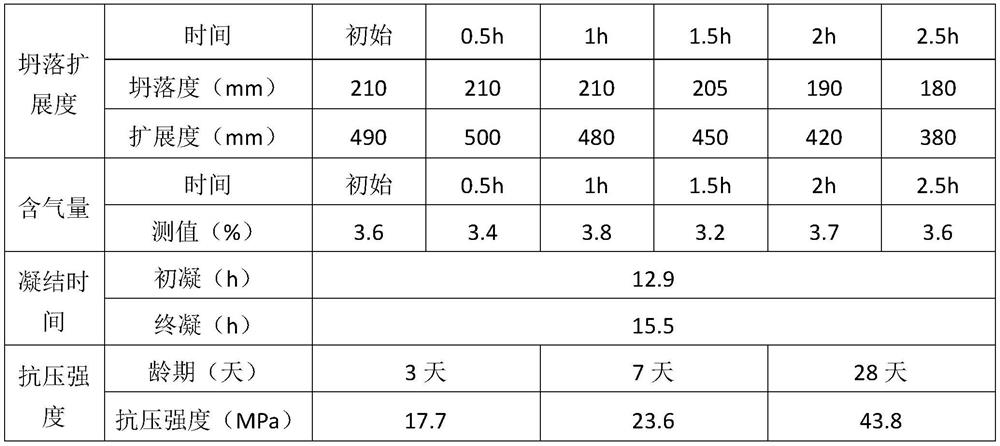

[0030] The performance results of the concrete mixed with the composite concrete admixture in Example 1 are shown in Table 1:

[0031] Table 1 adopts the concrete test result that the compound type admixture of embodiment 1 is mixed

[0032]

[0033]For the concrete in Example 1, the slump is kept within the range of 180mm to 210mm within 2.5 hours after the self-mixing machine, the expansion i...

Embodiment 2

[0035] Weigh 6.5 parts of polycarboxylate superplasticizer and 8 parts of slow-release polycarboxylate superplasticizer according to the proportion, mix them evenly, add water to dilute at a ratio of 1:6, and then add 2 parts of sodium gluconate, 1.5 parts of sucrose, 0.5 parts of sodium hexametaphosphate, 0.5 parts of sodium citrate, mixed and stirred evenly, the temperature of the solution during the preparation process does not exceed 35 ° C, and finally a composite concrete admixture is formed. The dosage is 0.9% of the total amount of cementitious materials, and 0.43 The water-binder ratio is mixed to produce concrete.

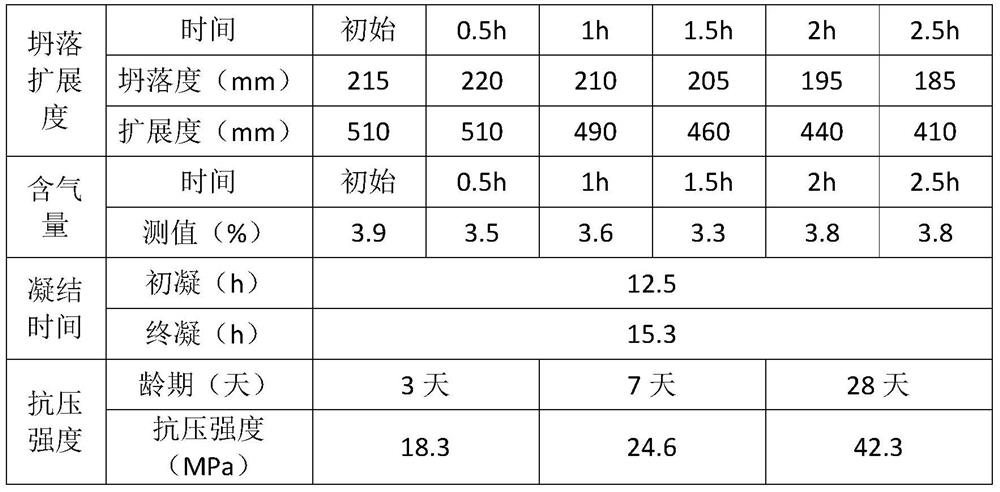

[0036] The performance results of the concrete mixed with the composite concrete admixture in Example 2 are shown in Table 2:

[0037] The concrete test result that table 2 adopts the composite type admixture of embodiment 2 to mix

[0038]

[0039] For the concrete in Example 2, the slump is maintained within the range of 180mm to 220mm within 2.5 ho...

Embodiment 3

[0041] Weigh 5.5 parts of polycarboxylate superplasticizer and 13.3 parts of slow-release polycarboxylate superplasticizer according to the ratio, mix and stir evenly, add water to dilute at a ratio of 1:7, then add 2.5 parts of sodium gluconate and 1 part of sucrose , 0.5 parts of sodium dihydrogen phosphate, 0.5 parts of tartaric acid, mixed and stirred evenly, the temperature of the solution during the configuration process does not exceed 35 ° C, and finally a composite concrete admixture is formed. The dosage is 1.0% of the total amount of cementitious materials, and 0.43 Water-binder ratio mixes concrete.

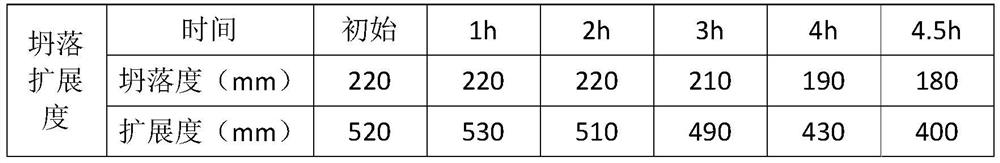

[0042] The performance results of the concrete mixed with the composite concrete admixture in Example 3 are shown in Table 3:

[0043] Table 3 adopts the concrete test result that the compound type admixture of embodiment 3 is mixed

[0044]

[0045]

[0046] For the concrete in Example 3, within 4.5 hours after the concrete was mixed out of the machine, the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com