Plastic tray material and preparation method thereof

A plastic tray and resin technology, applied in the field of plastic products, can solve problems such as weak anti-static performance and damage, achieve good electrical conductivity, improve anti-static performance, and improve poor heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

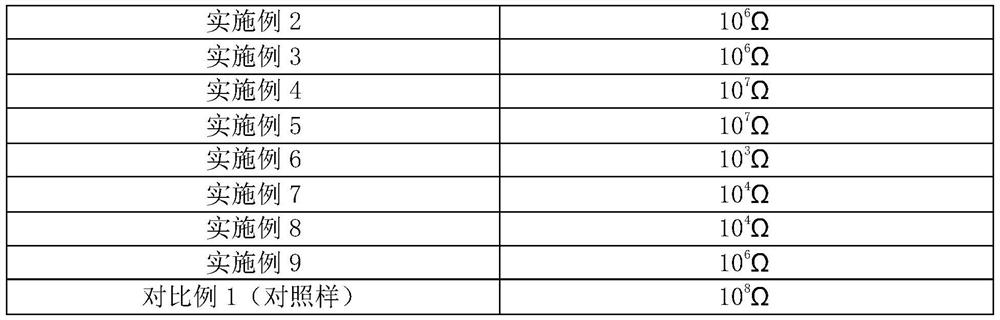

Embodiment 1

[0042] The plastic tray material includes the following components in mass percentage: conductive fiber modified PS resin 54.28%, ordinary PS resin 27.14%, carbon black 18.5%, antioxidant 1010 0.04% and antioxidant 168 0.04%;

[0043] The preparation method of conductive fiber modified PS resin is:

[0044] 1) Weigh 10 parts of PS resin and 3 parts of conductive fiber by weight, and the conductive fiber is made of polyester yarn and polyphenylene sulfide yarn interwoven and compounded at 1:1;

[0045] 2) soaking and softening the conductive fibers first, and then performing wet slitting to obtain chopped conductive fibers with a length of 3 mm;

[0046] 3) Disperse the chopped conductive fibers into the molten PS resin, send the blend into the screw extruder, stir and press the screw to make the two evenly blended;

[0047] 4) extruding, cooling, granulating and sieving the blend to obtain conductive fiber modified PS resin;

[0048] The preparation method of plastic tray mate...

Embodiment 2

[0055] The plastic tray material includes the following components in mass percentage: conductive fiber modified PS resin 50%, ordinary PS resin 29.9%, carbon black 20%, antioxidant 1010 0.05% and antioxidant 168 0.05%;

[0056] The preparation method of conductive fiber modified PS resin is the same as embodiment 1;

[0057] The preparation method of plastic tray material specifically comprises the following steps:

[0058] S1. Carbon black pre-treatment: crushing the carbon black and then grinding it into powder, and drying the carbon black powder after grinding;

[0059] S2. Premixing: premixing the carbon black powder, antioxidant 1010 and antioxidant 168 to obtain a premix;

[0060] S3. Add the conductive fiber modified PS resin, ordinary PS resin and premix into the mixing tank and mix for 10 minutes. The initial stirring speed is 400rpm, and the stirring speed is gradually increased at a speed of 200r / min to prepare the blend;

[0061] S4. Send the blend in S3 to the ...

Embodiment 3

[0064] The plastic tray material includes the following components in mass percentage: conductive fiber modified PS resin 59.94%, ordinary PS resin 25%, carbon black 15%, antioxidant 1010 0.03% and antioxidant 168 0.03%;

[0065] The preparation method of conductive fiber modified PS resin is the same as embodiment 1;

[0066] The preparation method of plastic tray material specifically comprises the following steps:

[0067] S1. Carbon black pre-treatment: crushing the carbon black and then grinding it into powder, and drying the carbon black powder after grinding;

[0068] S2. Premixing: premixing the carbon black powder, antioxidant 1010 and antioxidant 168 to obtain a premix;

[0069] S3. Add the conductive fiber modified PS resin, ordinary PS resin and premix into the mixing tank and mix for 10 minutes. The initial stirring speed is 400rpm, and the stirring speed is gradually increased at a speed of 200r / min to prepare the blend;

[0070] S4. Send the blended material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com