A flat profiling fabric and its forming process

A molding process and fabric technology, applied in fabrics, multi-strand fabrics, textiles, etc., can solve problems such as uneven addition and subtraction of warp yarns, improve designability, solve equipment capacity limitations, and realize fabric structure diversification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

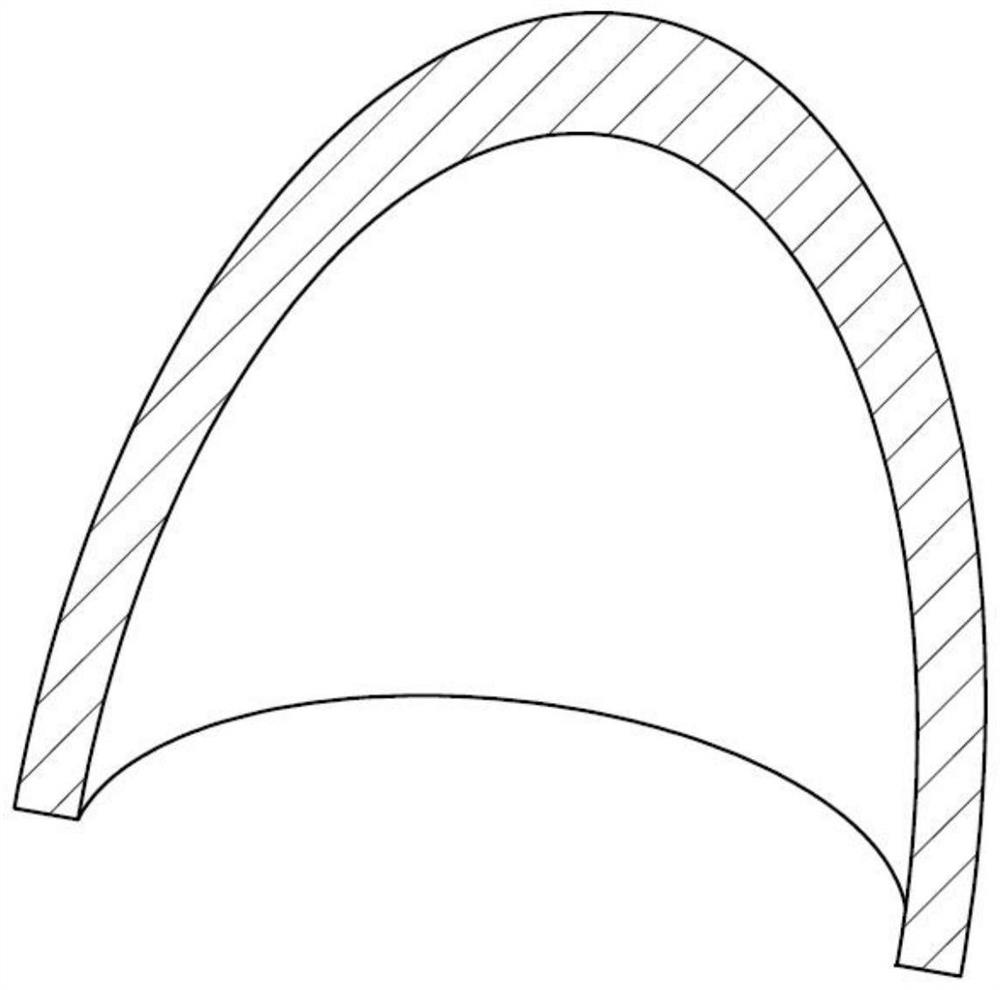

[0081] The developed planar profiling fabric is conical, with a half-cone angle of 12°, a fabric height of 50mm, an outer diameter of the big end of 500mm, and a fabric equal wall thickness of 10mm. The process parameter design is shown in Table 1.

[0082] Table 1 Fabric process parameter table

[0083]

[0084]

[0085] The specific operation steps are as follows:

[0086] (1) Select the quartz fiber whose specification is 190Tex according to Figure 6 Arranged in a matrix as shown, one end of the quartz fiber is connected to the length-fixing device of common three-dimensional weaving equipment, or stored in a yarn storage device or pan head commonly used in textile equipment; the other end of the quartz fiber is fixed to the yarn fixing device.

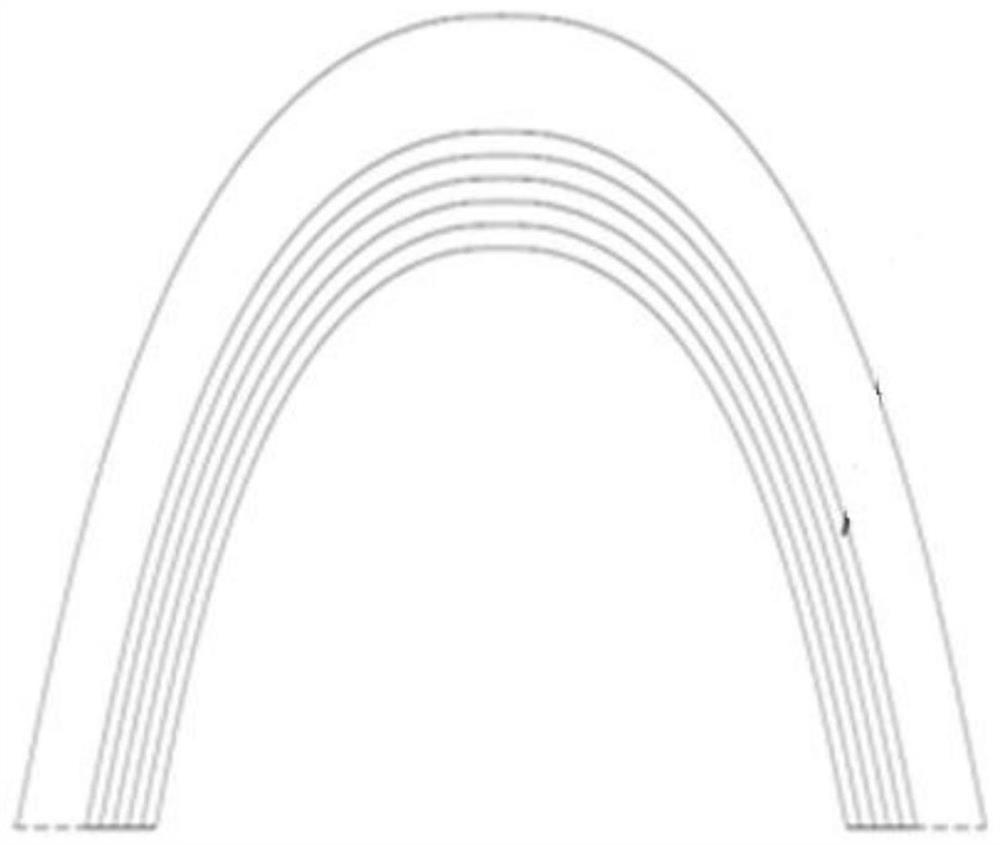

[0087] (2) According to Figure 6 As shown, the warp yarns are arranged in 4 groups, respectively Z 1 ,Z 2 ,Z 3 ,Z 4 , each group of warp columns is 394 columns.

[0088] (3) After completing step (2), adjust the pos...

Embodiment 2

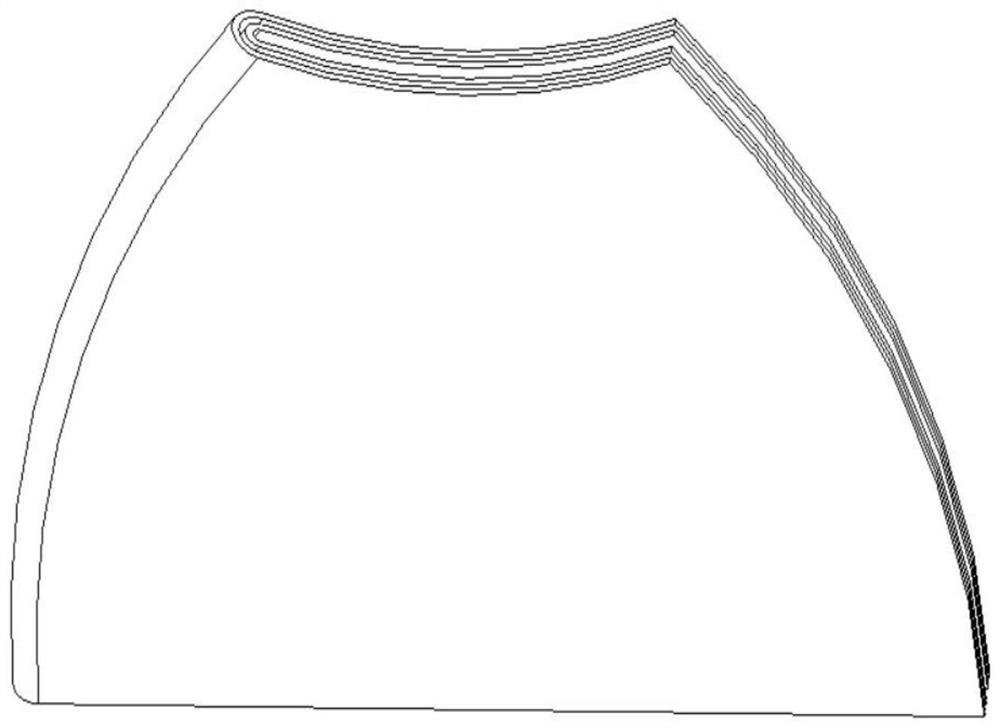

[0096] The developed planar profiling fabric is cylindrical, the fabric height is 100mm, the fabric outer diameter is 300mm, and the fabric equal wall thickness is 6mm. The process parameter design is shown in Table 2.

[0097] Table 2 fabric process parameter list

[0098]

[0099] The specific operation steps are as follows:

[0100] (1) Select carbon fiber with a specification of 198Tex according to Figure 8 Arranged in a matrix as shown, one end of the carbon fiber is connected to the length-fixing device of common three-dimensional weaving equipment, or stored in a yarn storage device or pan head commonly used in textile equipment; the other end of the quartz fiber is fixed to the yarn fixing device.

[0101] (2) According to Figure 8 As shown, the warp yarns are arranged in 4 groups, respectively Z 1 ,Z 2 ,Z 3 ,Z 4 .

[0102] (3) After completing step (2), adjust the position of the warp shedding device as follows: Figure 8 As shown, the odd column is 2 po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com