Superlattice material embedded with quantum wires, preparation method of superlattice material, infrared band luminescent material and detector

A technology of infrared bands and luminescent materials, which is applied in nanotechnology for materials and surface science, semiconductor devices, and final product manufacturing. It can solve problems such as easy discovery, and achieve the effect of simple operation and obvious structural advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

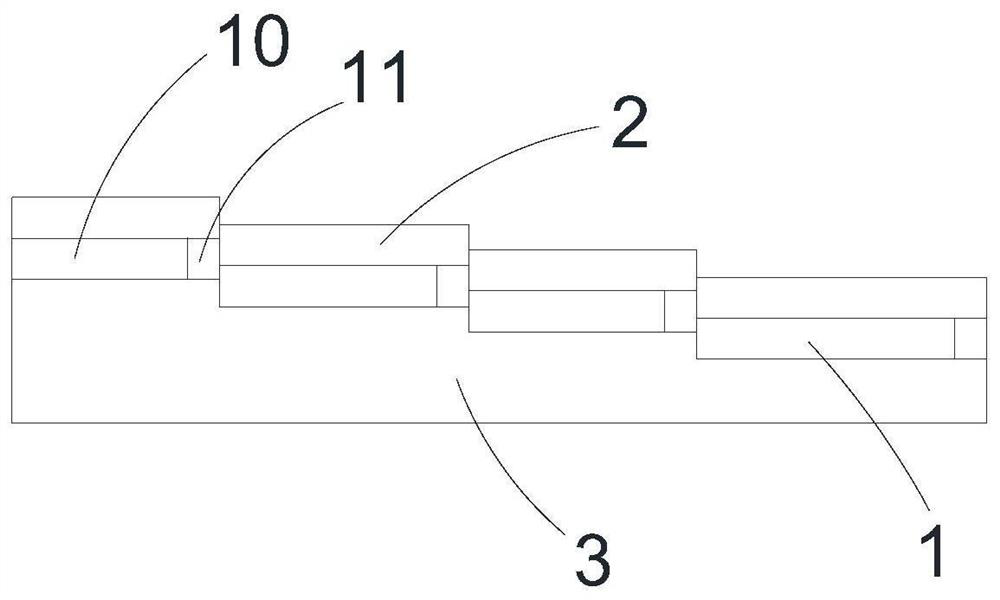

[0063] Such as figure 1 As shown, this embodiment provides a superlattice structure embedded with InAs quantum wires. The superlattice structure embedded with InAs quantum wires includes an InAs / GaSb layer 1 and a single substance layer 2. In the InAs / GaSb layer 1, the GaSb portion 10 accounts for 80%, the InAs portion 11 accounts for 20%, and the single substance layer 2 For GaSb.

[0064] The thickness of the InAs / GaSb layer 1 and the single substance layer 2 are both 10ML.

[0065] The preparation method is as follows:

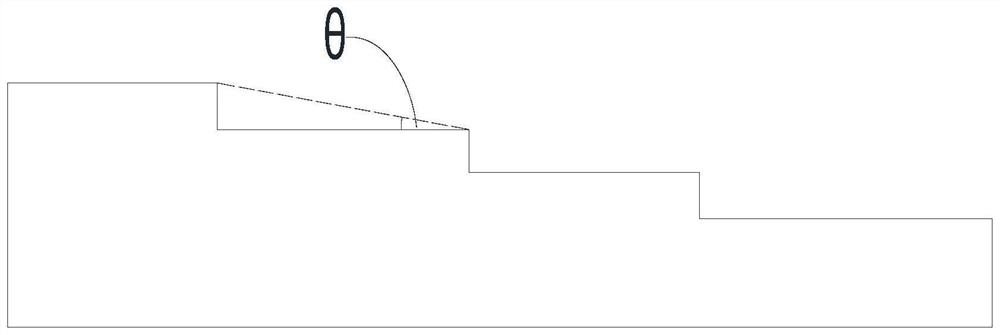

[0066] The substrate 3 is a GaSb substrate with an inclination angle, the inclination angle is 2.86°, and the step width is about 6 nm. The growth parameters include: the substrate temperature is 350°C, and the III / V beam ratio is 1:1.

[0067] Such as figure 2 As shown, the inclination angle θ represents the ratio of the height to the width of the step surface.

[0068] Growth of InAs / GaSb layer 1:

[0069] First turn on the Ga source and Sb source, observe the c...

Embodiment 2

[0083] Reference figure 1 As shown, this embodiment provides a superlattice structure embedded with InAs quantum wires. The superlattice structure embedded in the InAs quantum wire includes an InAs / GaSb layer 1 and a single substance layer 2. In the InAs / GaSb layer 1, the GaSb portion 10 accounts for 90%, the InAs portion 11 accounts for 10%, and the single substance layer 2 For GaSb.

[0084] The thickness of the InAs / GaSb layer 1 and the single substance layer 2 are both 20ML.

[0085] The preparation method is as follows:

[0086] The substrate 3 is a GaSb substrate with an inclination angle, the inclination angle is 2.86°, and the step width is about 6 nm. The growth parameters include: the substrate temperature is 550°C, and the III / V beam ratio is 1:5.

[0087] In other embodiments, the inclination angle of the substrate can be between 1°, 2°, 3°, 4°, 5°, 6°, 7°, 8°, 9°, 10°, etc. Any value.

[0088] Growth of InAs / GaSb layer 1:

[0089] First turn on the Ga source and Sb sourc...

Embodiment 3

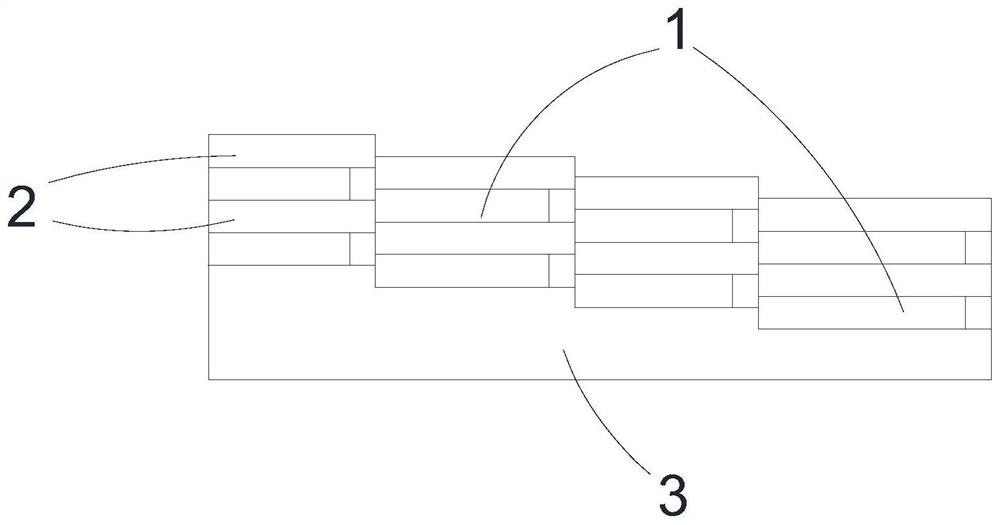

[0097] Such as Picture 11 As shown, this embodiment provides a superlattice structure embedded with GaSb quantum wires. The superlattice structure embedded in the GaSb quantum wire includes an InAs / GaSb layer 1 and a single material layer 2. InAs / GaSb layer 1 InAs part 11 accounts for 90%, GaSb part 10 accounts for 10%, and single material layer 2 For InAs.

[0098] The thickness of the InAs / GaSb layer 1 and the single substance layer 2 are both 10ML.

[0099] The preparation method is as follows:

[0100] The substrate 3 is a GaSb substrate with an inclination angle, the inclination angle is 2.86°, and the step width is about 6 nm. The growth parameters include: the substrate temperature is 150°C, and the III / V beam ratio is 1:3.

[0101] In other embodiments, the substrate 3 may be any one of a GaAs substrate, an InAs substrate, an InP substrate, and a Si substrate.

[0102] Growth of InAs / GaSb layer 1:

[0103] First turn on the In source and As source, observe the coverage of InA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com