A preparation method of Cu-doped hollow hexagonal ZIF-8 material for zinc-air batteries

A ZIF-8, zinc-air battery technology, applied in the direction of fuel cell-type half-cell and primary cell-type half-cell, battery electrodes, circuits, etc., can solve the problem of increasing mass transfer capacity, low ORR activity, zinc-air battery, etc. problem, to achieve the effect of increasing catalytic activity, wide application and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1: put dimethylimidazole and zinc nitrate hexahydrate into methanol solution at a ratio of 4:1 and stir for 24 hours to obtain ZIF-8, centrifuge and dry;

[0044] Step 2: put ZIF-8 into water, put tannic acid solution into the above solution, stir to obtain hollow ZIF-8, centrifuge and dry;

[0045] Step 3: Put dicyandiamide in a muffle furnace and calcinate to obtain g-C 3 N 4 ;

[0046] Step 4: Put the hollow ZIF-8 into the methanol solution and put the methanol solution in which copper nitrate is dissolved into the above solution and stir to obtain the precursor CuHZ-8, centrifuge and dry;

[0047] Step 5: Combine CuHZ-8 and g-C 3 N 4 Mix and grind evenly in a mortar and then put it into a tube furnace for calcination at 800°C to obtain C-CuHZ-8;

[0048] Step 6: Wash C-CuHZ-8 with 0.5M sulfuric acid, filter and dry.

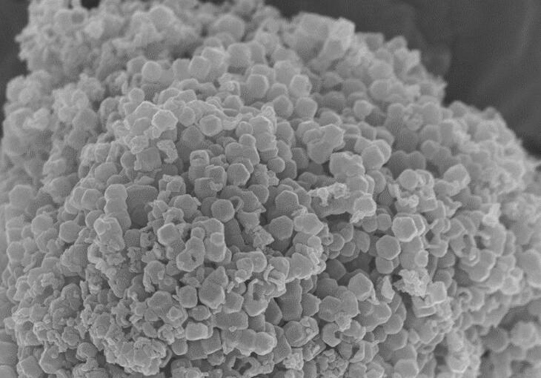

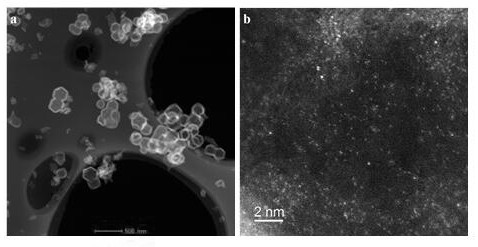

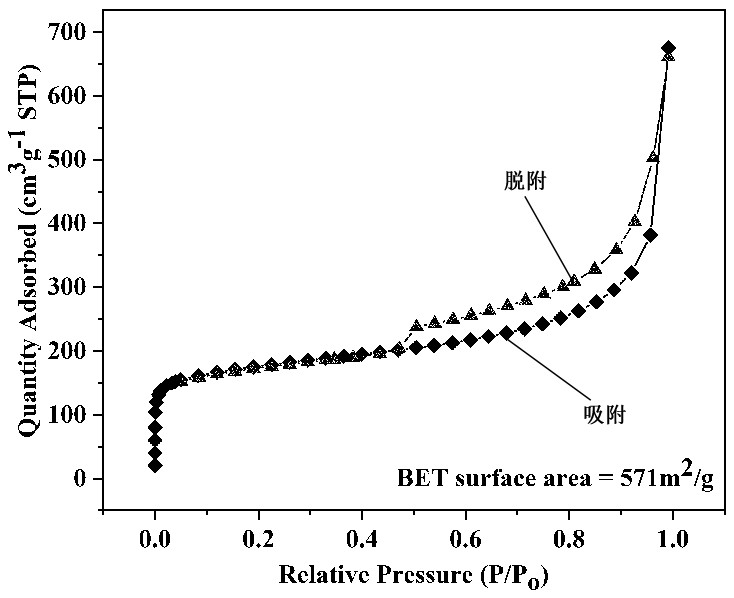

[0049] The copper-doped hollow ZIF-8 material prepared by the above method was characterized by scanning electron microscopy. In the experi...

Embodiment 2

[0058] Step 1: put dimethylimidazole and zinc nitrate hexahydrate into methanol solution at a ratio of 4:1 and stir for 24 hours to obtain ZIF-8, centrifuge and dry;

[0059] Step 2: Put ZIF-8 into water, put 8 mg / mL tannic acid solution into the above solution, stir to obtain hollow ZIF-8, centrifuge and dry;

[0060] Step 3: Put dicyandiamide into a muffle furnace and calcinate at 550°C for 4 hours to obtain g-C 3 N 4 ;

[0061] Step 4: Put the hollow ZIF-8 into the methanol solution and put the methanol solution in which copper nitrate is dissolved into the above solution and stir to obtain the precursor CuHZ-8, centrifuge and dry;

[0062] Step 5: Combine CuHZ-8 and g-C 3 N 4 Mix and grind evenly in a mortar and then put it into a tube furnace for calcination at 700°C to obtain C-CuHZ-8;

[0063] Step 6: Wash C-CuHZ-8 with 0.5M sulfuric acid, filter and dry at 60°C.

Embodiment 3

[0065] Step 1: put dimethylimidazole and zinc nitrate hexahydrate into methanol solution at a ratio of 3:1 and stir for 24 hours to obtain ZIF-8, centrifuge and dry;

[0066] Step 2: put ZIF-8 into water, put tannic acid solution into the above solution, stir to obtain hollow ZIF-8, centrifuge and dry;

[0067] Step 3: Put dicyandiamide into a muffle furnace and calcinate at 550°C for 4 hours to obtain g-C 3 N 4 ;

[0068] Step 4: Put the hollow ZIF-8 into the methanol solution and put the methanol solution in which copper nitrate is dissolved into the above solution and stir to obtain the precursor CuHZ-8, centrifuge and dry;

[0069] Step 5: Combine CuHZ-8 and g-C 3 N 4 Mix and grind evenly in a mortar and then put it into a tube furnace for calcination at 800°C to obtain C-CuHZ-8;

[0070] Step 6: Wash C-CuHZ-8 with 0.5M sulfuric acid, filter and dry at 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com