A kind of gas diffusion layer and its preparation method and use

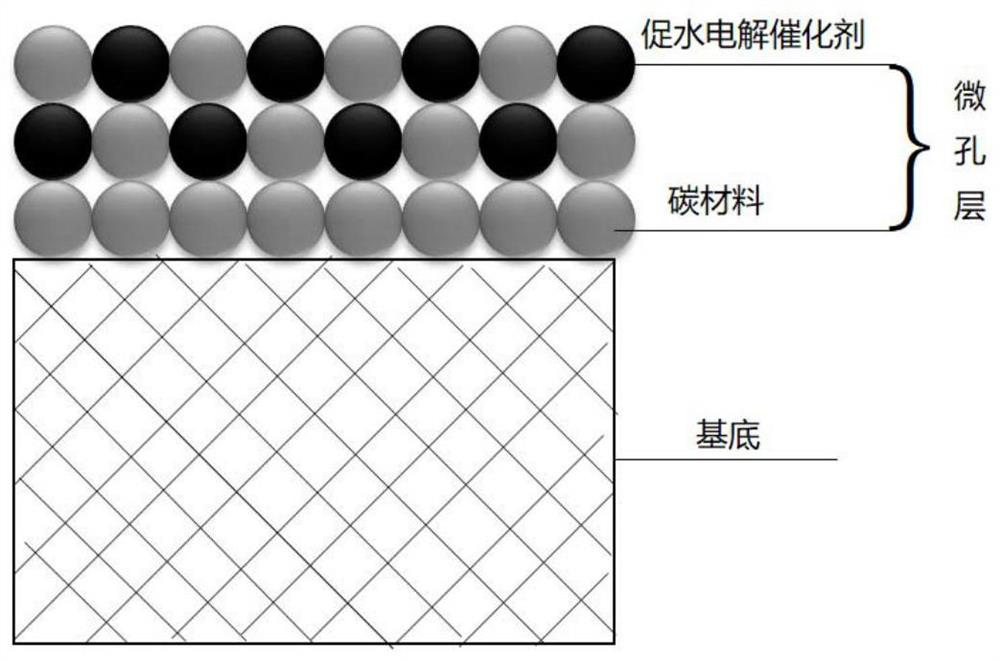

A technology of gas diffusion layer and microporous layer, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of increasing the complexity and cost of the battery system, and achieve excellent anti-reversal ability, stability of the overall structure and performance Good, reduce the effect of reverse polarity conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

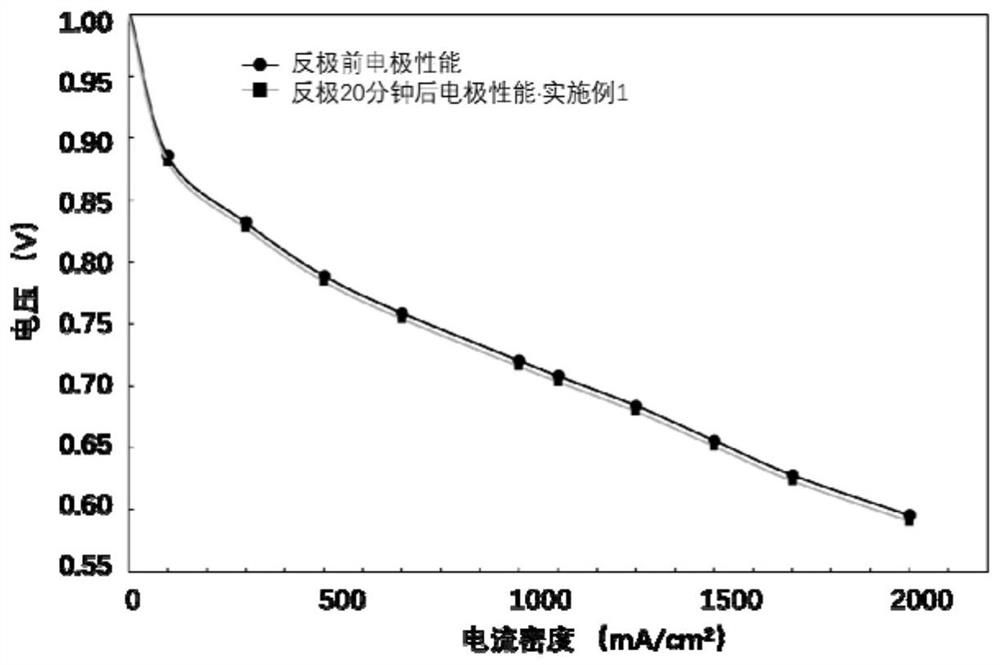

Embodiment 1

[0072] This embodiment provides a method for preparing a gas diffusion layer, comprising the following steps:

[0073] (1) Add acetylene black and polytetrafluoroethylene to the aqueous solution of polyvinylpyrrolidone, stir and ultrasonically disperse for 60 minutes, and the ultrasonic power used is 800W to obtain the microporous layer slurry, then add ruthenium chloride and stir to obtain The microporous layer slurry after treatment, the loading amount of acetylene black in the microporous layer of the gas diffusion layer is controlled to be 3mg / cm 2 , the quality of the polytetrafluoroethylene is 25% of the mass of acetylene black, and the mass ratio of the ruthenium chloride to the acetylene black is 0.08;

[0074] (2) Coat the microporous layer slurry treated in step (1) onto carbon paper so that the coating thickness is 45 μm, raise the temperature to 500° C. in nitrogen and keep it for 60 minutes until the ruthenium chloride is decomposed into a simple substance Ruthen...

Embodiment 2

[0077] This embodiment provides a method for preparing a gas diffusion layer, comprising the following steps:

[0078] (1) Graphite powder and polytetrafluoroethylene are added in the aqueous solution of polyvinylpyrrolidone, carry out stirring, ultrasonic dispersion 80 minutes, used ultrasonic power is 900W, obtain microporous layer slurry, then add ruthenium chloride, stir, obtain The microporous layer slurry after treatment, the loading capacity of the graphite powder in the microporous layer of the gas diffusion layer is controlled to be 8 mg / cm 2 , the quality of polytetrafluoroethylene is 25% of graphite powder quality, and the mass ratio of described ruthenium chloride and graphite powder is 0.02;

[0079] (2) Spin-coat the microporous layer slurry treated in step (1) onto carbon paper so that the coating thickness is 60 μm, raise the temperature to 600° C. in nitrogen and keep it for 90 minutes until the ruthenium chloride is decomposed into elemental ruthenium and hy...

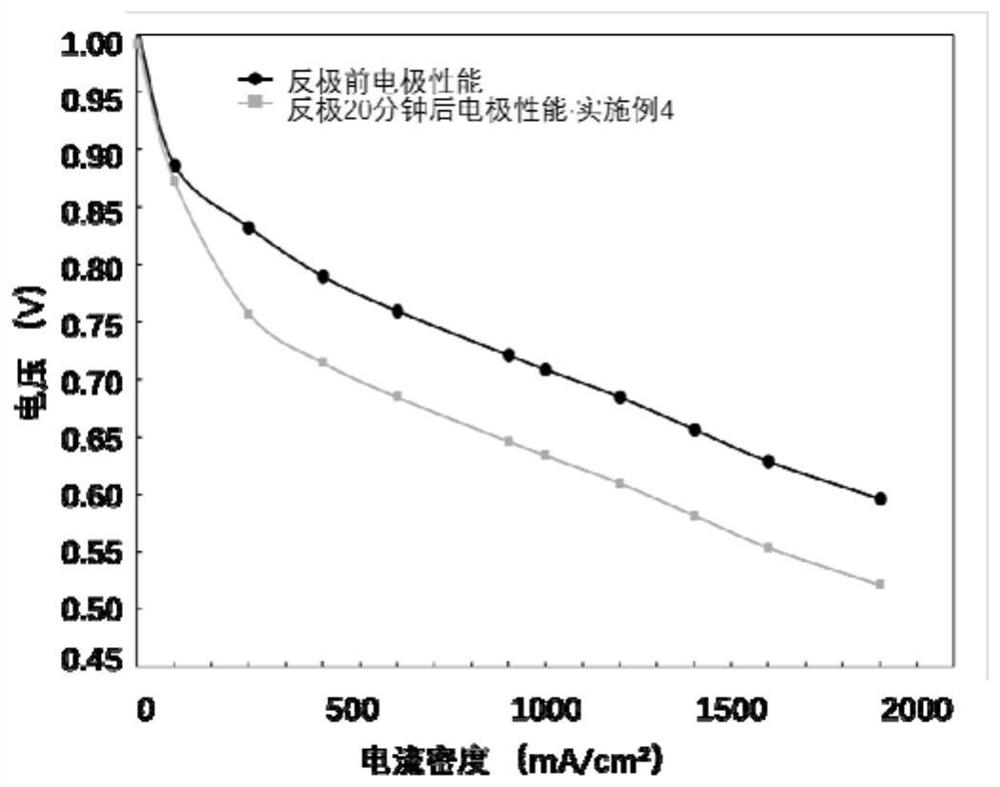

Embodiment 3

[0081] This embodiment provides a method for preparing a gas diffusion layer, comprising the following steps:

[0082] (1) Add activated carbon and polytetrafluoroethylene to the aqueous solution of polyvinylpyrrolidone, stir and ultrasonically disperse for 20 minutes. The ultrasonic power used is 800W to obtain a microporous layer slurry, then add ruthenium chloride and stir to obtain a treated After the microporous layer slurry, the loading amount of activated carbon in the microporous layer of the gas diffusion layer is controlled to be 0.5 mg / cm 2 , the quality of the polytetrafluoroethylene is 25% of the activated carbon quality, and the mass ratio of the ruthenium chloride to the activated carbon is 0.1;

[0083] (2) Spin-coat the microporous layer slurry treated in step (1) onto the mesh titanium substrate so that the coating thickness is 10 μm, raise the temperature to 500 ° C in nitrogen and keep it for 30 minutes until the ruthenium chloride decomposes The gas diffu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com