Integrated directional antenna

A directional antenna and antenna radiator technology, applied in the direction of resonant antenna, antenna grounding device, antenna grounding switch structure connection, etc., can solve the problems of large reflection coefficient, low profile, low overall antenna efficiency, etc., to achieve simplified structure and high orientation Effect of radiation, high radiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

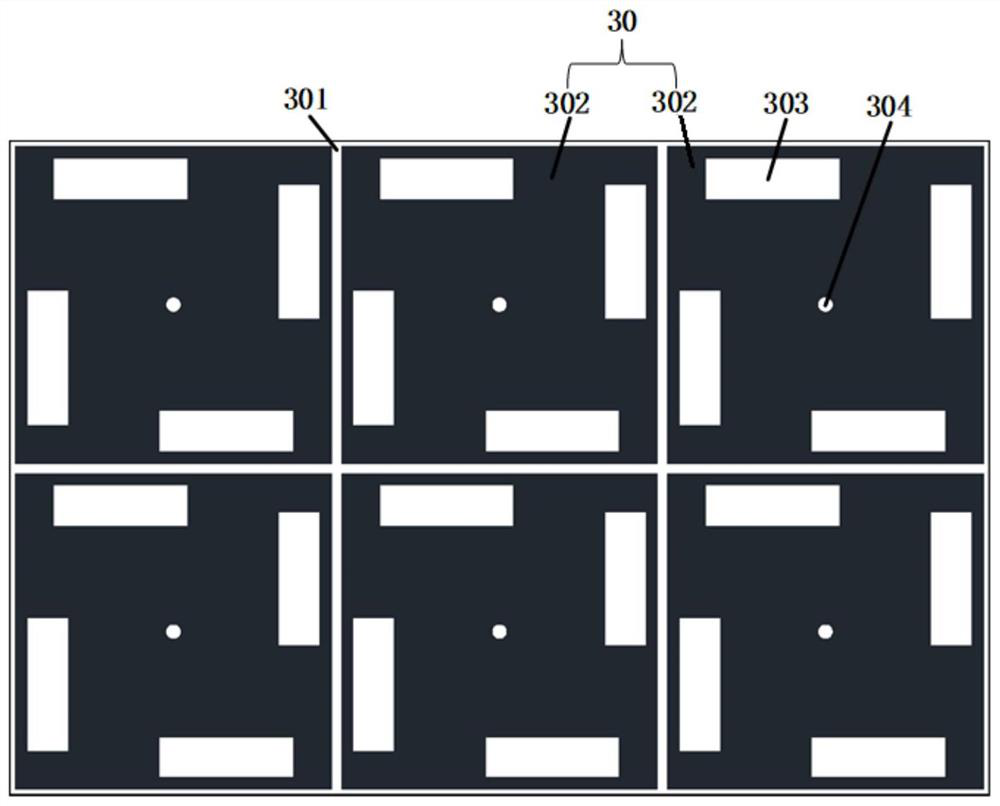

[0059] Such as Figure 4 As shown, on each metal patch unit 302 , there are multiple slots 303 , and the multiple slots 303 are distributed around the metal via hole 304 .

[0060] A plurality of grooves 303 are rectangular grooves, and each metal patch unit 302 is provided with four rectangular grooves, and the four rectangular grooves are arranged around the metal via hole 304. On each metal patch unit 302, two adjacent The length direction of the rectangular groove is vertical.

[0061] It should be noted that the postures of the rectangular slots on each metal patch unit 302 may be different, for example, the rectangular slots may be inclined at a preset angle relative to the horizontal direction or the vertical direction, and the like.

Embodiment 2

[0063] Such as Figure 5 As shown, on each metal patch unit 302 , there are multiple slots 303 , and the multiple slots 303 are distributed around the metal via hole 304 .

[0064] The plurality of grooves 303 are arc-shaped strip-shaped grooves, and each metal patch unit 302 is respectively provided with four arc-shaped strip-shaped grooves, and the four arc-shaped strip-shaped grooves are arranged around the metal via hole 304, and each The centers of the arc-shaped strip grooves coincide.

Embodiment 3

[0066] Such as Figure 6 As shown, on each metal patch unit 302 , there are multiple slots 303 , and the multiple slots 303 are distributed around the metal via hole 304 .

[0067] The plurality of grooves 303 are arc-shaped strip-shaped grooves, and each metal patch unit 302 is respectively provided with four arc-shaped strip-shaped grooves, and the four arc-shaped strip-shaped grooves are arranged around the metal via hole 304, and each The center of the arc-shaped strip groove coincides with the center of the metal via hole 304 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com