Thermoelectric power generation device utilizing thermochemical reaction

A technology of thermochemical reaction and temperature difference power generation, applied in the direction of generators/motors, electrical components, etc., can solve problems such as mismatching between the temperature dependence of thermoelectric materials, achieve structural optimization, ensure high efficiency, and reduce temperature gradients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

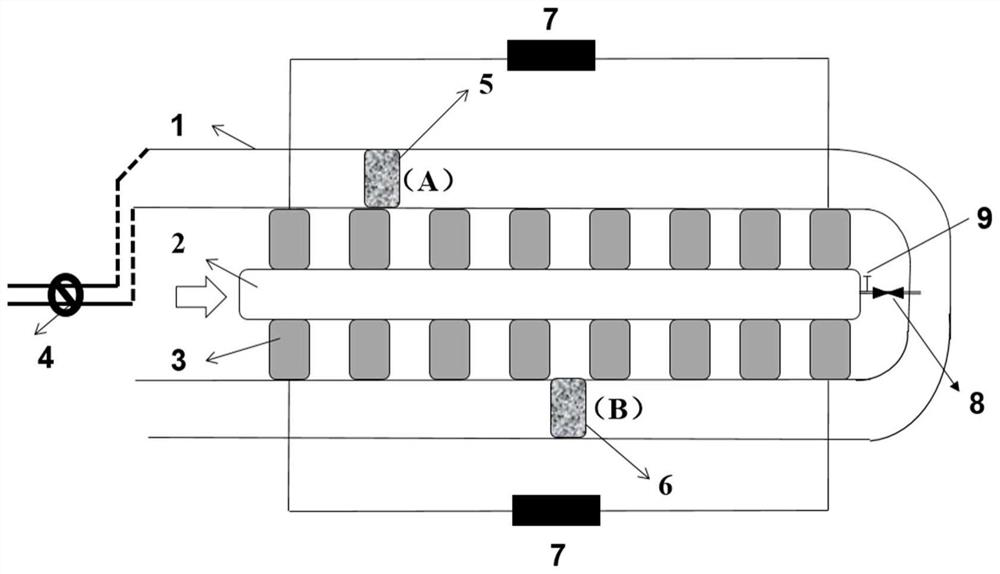

[0034] The side view of the structure of thermochemical reaction thermoelectric power generation device is as follows figure 1 As shown, it mainly includes a U-shaped waste heat fluid channel 1, a cooling water channel 2, a semiconductor thermoelectric module 3, an endothermic reactor 5, an exothermic reactor 6, a fluid flow control valve 4, an accumulator 7, a micro nozzle 8 and a nozzle Pipe control valve 9.

[0035] The U-shaped waste heat fluid channel includes a thermal fluid inlet channel and a thermal fluid outlet channel. The endothermic reactor is arranged on the thermal fluid inlet channel of the U-shaped waste heat fluid channel, and the exothermic reactor is arranged on the thermal fluid of the U-shaped waste heat fluid channel. Exit channel;

[0036] The cooling water channel is arranged on the two side channels of the U-shaped waste heat fluid channel, that is, the middle part of the hot fluid inlet section channel and the hot fluid outlet section channel;

[003...

no. 2 example

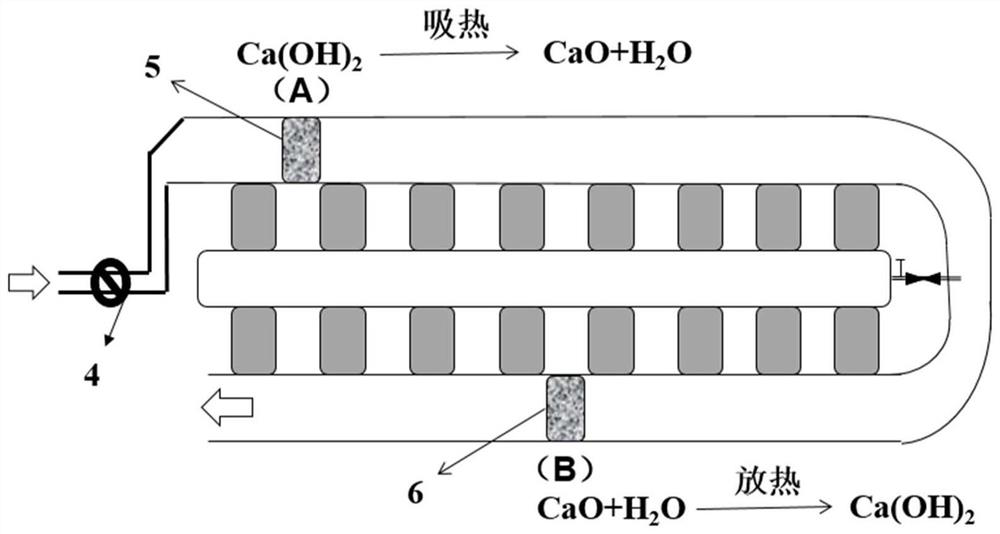

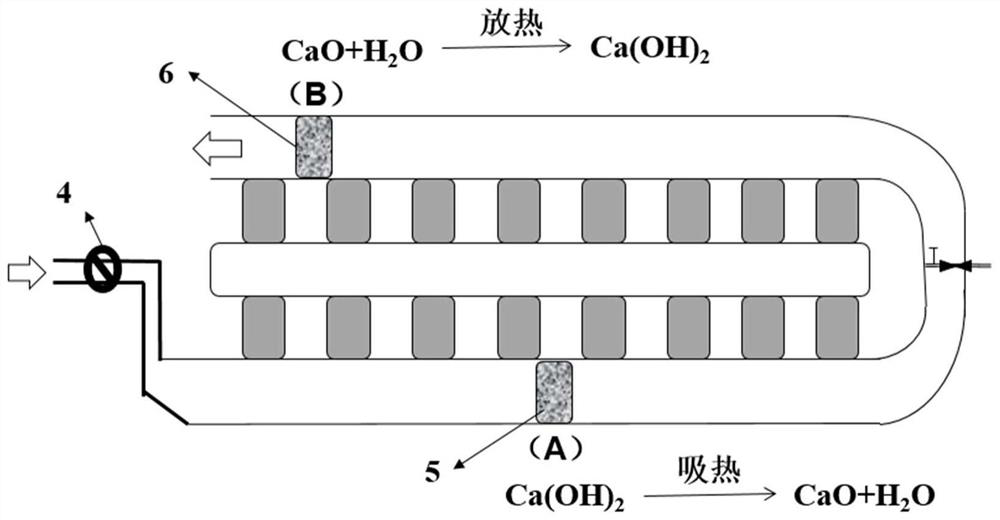

[0050] by chemical reaction As an example to illustrate the thermochemical energy storage process, a working cycle can be divided into two stages, and enters the first stage at the beginning of work, such as figure 2 As shown, the fluid flow direction control valve 4 is opened in the forward direction, and the chemical energy storage substance A in the endothermic reactor 5 is Ca(OH) 2 , the chemical energy storage substance B in the exothermic reactor 6 is CaO; the waste heat fluid flows through the U-shaped waste heat fluid channel 1, and first flows through the chemical energy storage substance Ca(OH) built in the endothermic reactor 5 2 , Ca(OH) 2 An endothermic reaction occurs at high temperature, it begins to convert into CaO, and a certain amount of water vapor is generated, that is, the reaction Ca(OH) 2 →CaO+H 2 O, the temperature of the fluid is lowered after absorbing heat; after that, the waste heat fluid flows through the chemical energy storage material CaO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com