Pesticide spraying equipment for soil treatment

A soil treatment and insecticide technology, applied in the field of soil treatment, can solve problems such as fatigue, reduced efficiency of insecticide, and influence on insecticide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

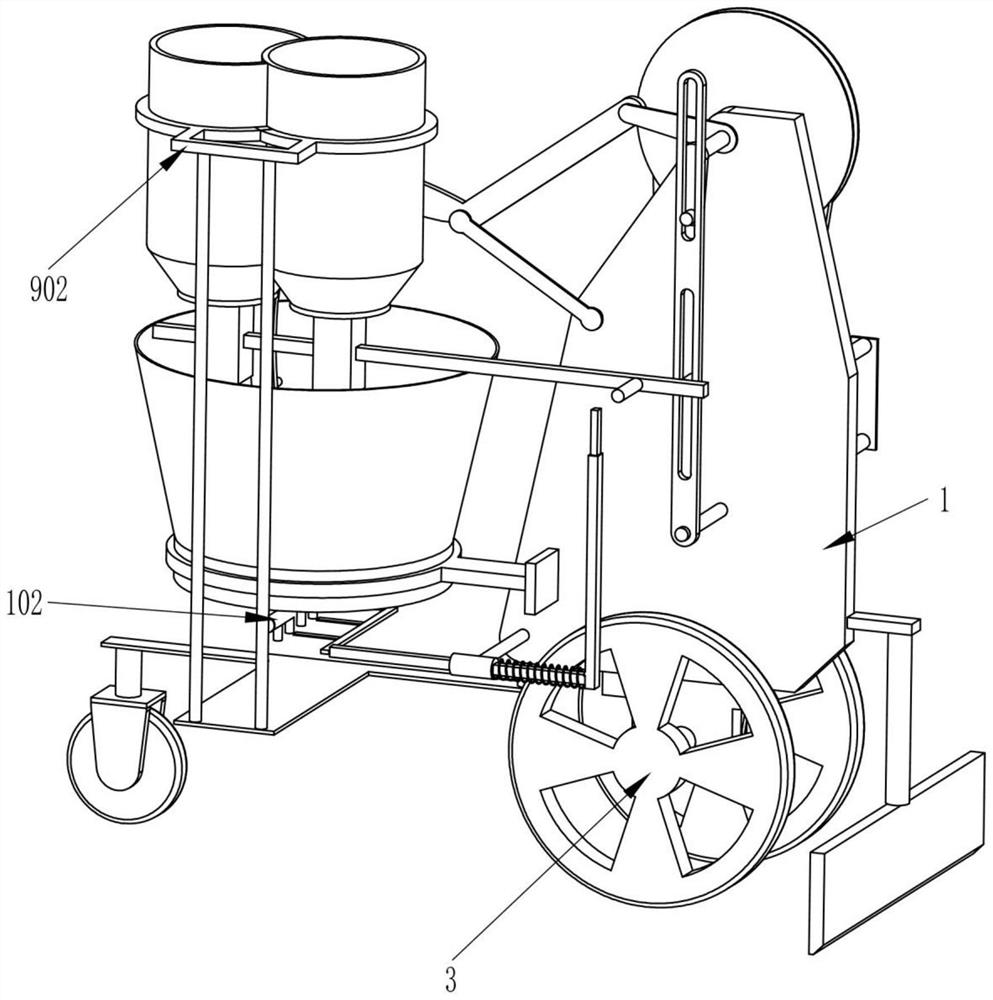

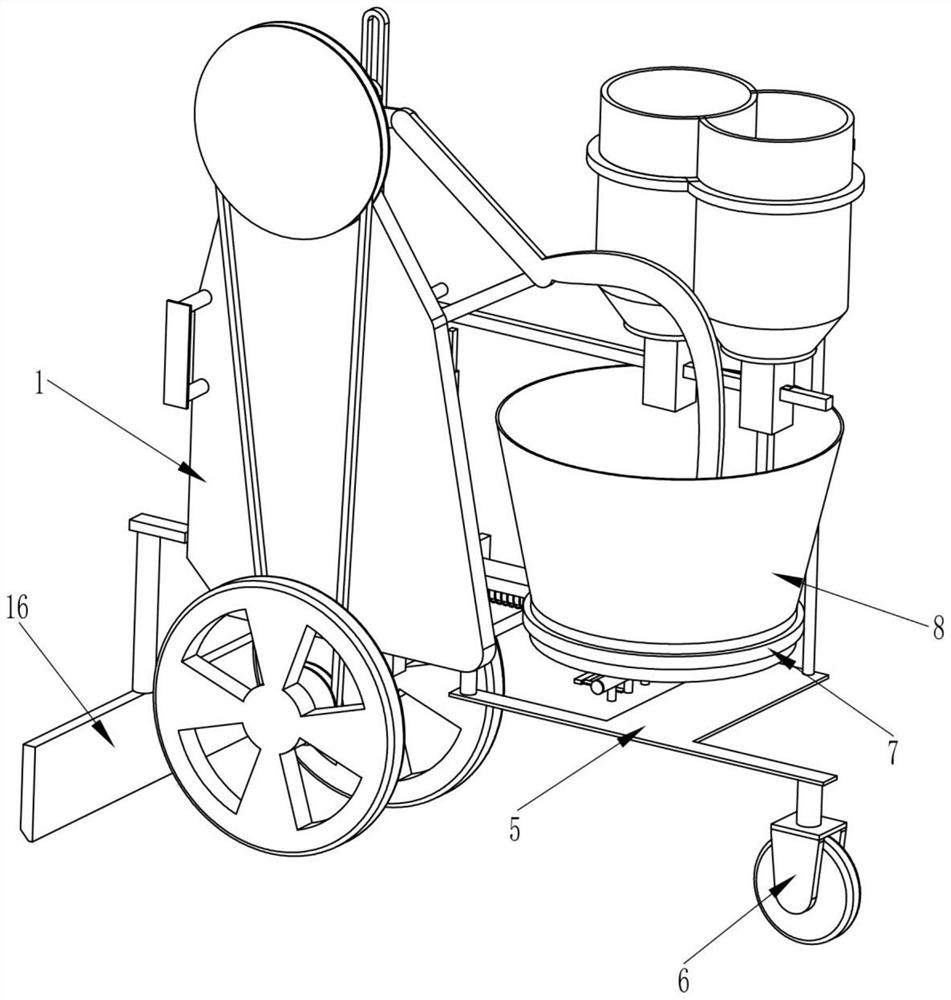

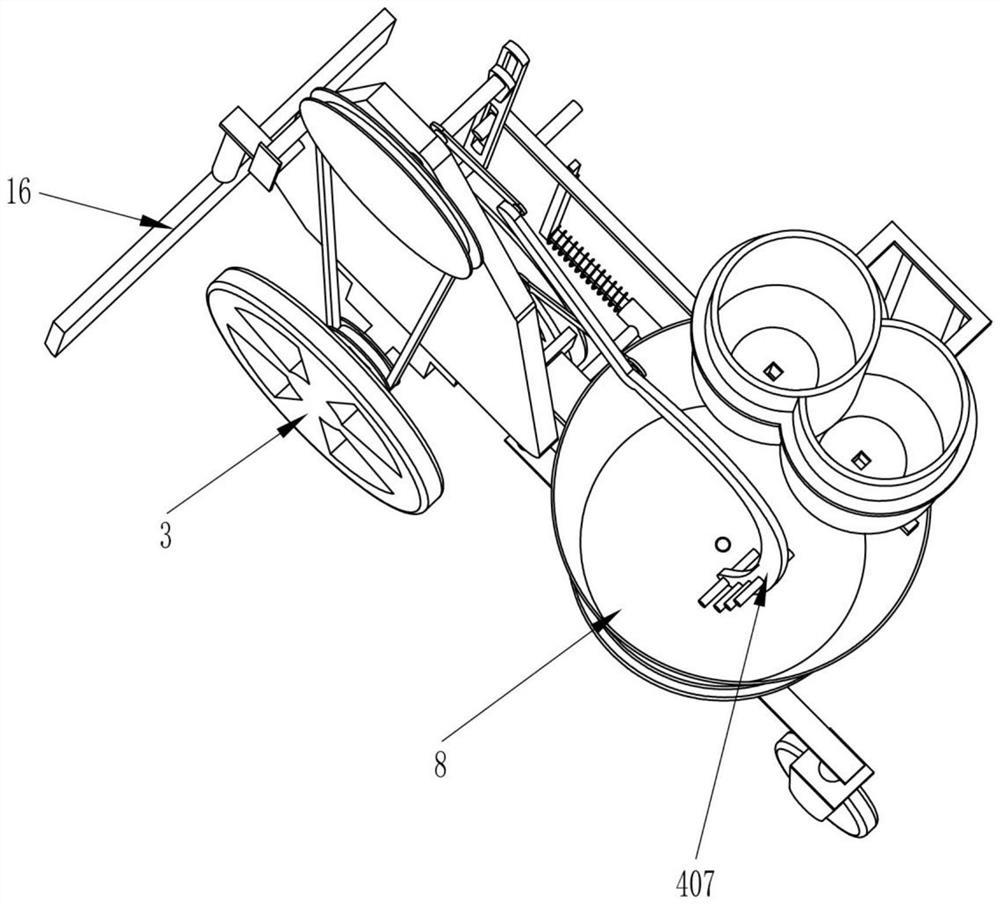

[0022] An insecticide spraying device for soil treatment, such as Figure 1-6 As shown, it includes a mounting plate 1, a handle 101, a drain pipe 102, a transmission shaft 2, a roller 3, an insecticide dilution stirring mechanism 4, a T-shaped plate 5, a wheel base 6, a support frame 7, a stirring frame 8 and Intermittent liquid supply mechanism 9, a handle 101 is installed on one side of the vertically arranged mounting plate 1, a transmission shaft 2 is installed on the mounting plate 1 through a bearing, and the two rollers 3 are installed on both sides of the transmission shaft 2 respectively. end, the insecticide dilution stirring mechanism 4 that can stir the insecticide is installed on the installation plate 1 and the transmission shaft 2, one end of the T-shaped plate 5 is installed on the lower end of the installation plate 1, and the wheel base 6 is fixedly installed on the The other end of the T-shaped plate 5, the supporting frame 7 that plays a supporting role is...

Embodiment 2

[0027]On the basis of Embodiment 1, such as Figure 1-6 As shown, a control blanking mechanism is also included, and the control blanking mechanism includes a guide frame 10, a sliding frame 11, a liquid baffle 12, a telescopic rod 13, a compression spring 14 and a push rod 15, and the guide frame 10 passes through The way of welding is fixedly installed on the side surface of the mounting plate 1, the sliding frame 11 is slidably installed on the guide frame 10, the sliding frame 11 can move left and right along the guide frame 10, and the liquid baffle plate 12 is fixedly installed on the One end of the sliding frame 11, the telescopic rod 13 is fixedly installed on the other end of the sliding frame 11, the compression spring 14 capable of resetting the sliding frame 11 is connected between the guide frame 10 and one end of the telescopic rod 13 and the sliding frame 11 passes through the compressed The spring 14, the push rod 15 is fixedly installed on the slotted rod 905 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap