Oil-resistant adsorption-resistant low-tension foam oil-displacing agent and preparation method and application thereof

A foam flooding and anti-adsorption technology, which is applied in chemical instruments and methods, earthwork drilling, and fluid production, etc. Adsorption is not mentioned, to achieve the effect of reducing construction cost, improving heterogeneity, and easy purchase of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

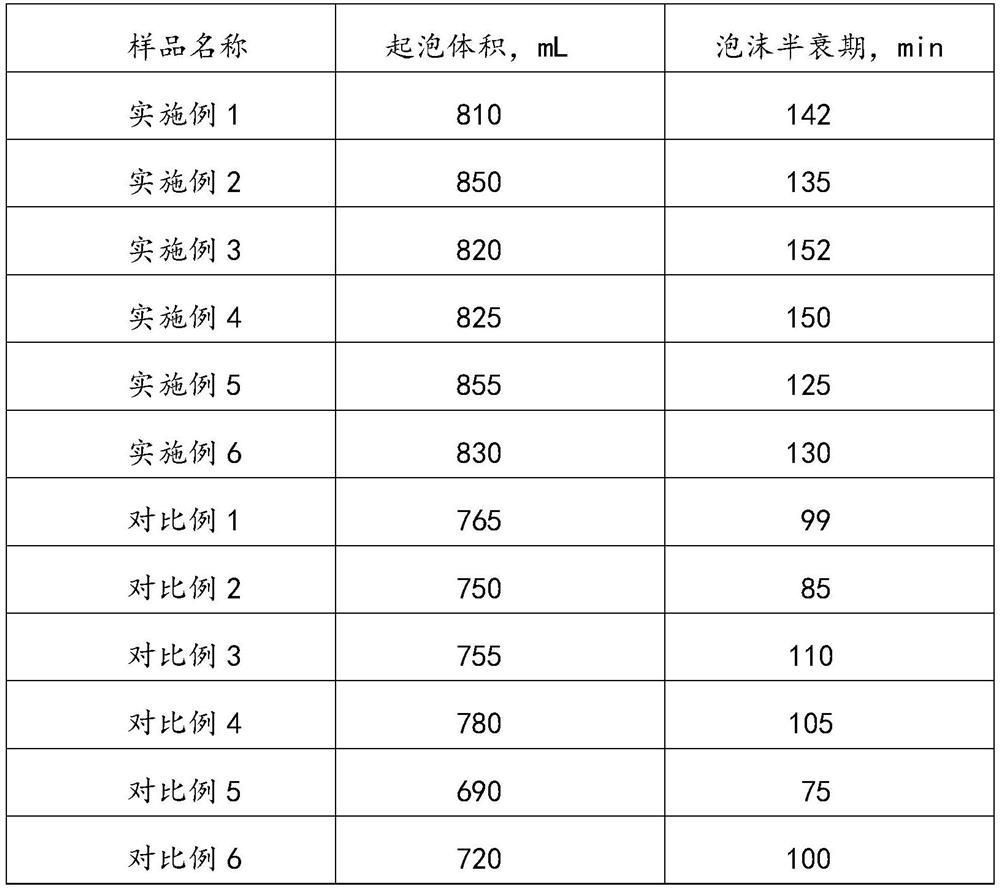

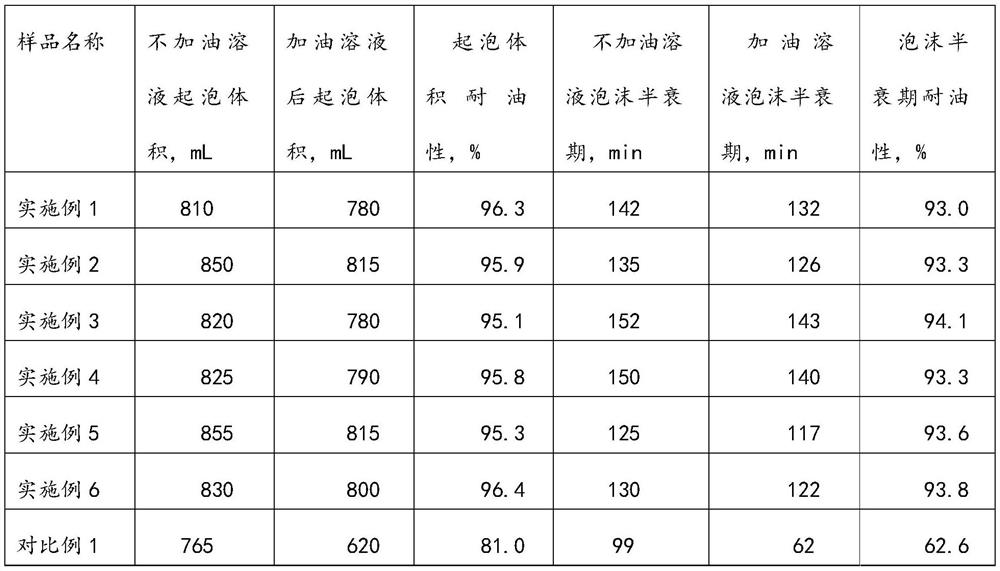

Examples

Embodiment 1

[0040] Add 200kg of water into the reactor, control the temperature at 50°C, add 100kg of cocoic acid monoisopropanolamide, stir to dissolve and mix well, then add 400kg of fatty alcohol polyoxyethylene ether glucoside (R 1=12, m=2, n=3) and 100kg ethanol, stirred and dissolved evenly, then added 200kg α-sodium olefin sulfonate (R 2 =9, n=2), and stir evenly to obtain an oil-resistant, anti-adsorption and low-tension foam oil displacement agent.

Embodiment 2

[0042] Add 200kg of water into the reactor, control the temperature at 52°C, add 110kg of lauric acid monoisopropanolamide, stir to dissolve and mix well, then add 380kg of fatty alcohol polyoxyethylene ether glucoside (R 1 =13, m=2, n=4) and 90kg methanol, stir and dissolve evenly, then add 220kg α-sodium olefin sulfonate (R 2 =10, n=3), and stir evenly to obtain an oil-resistant, anti-adsorption, low-tension foam oil displacement agent.

Embodiment 3

[0044] Add 200kg of water into the reactor, control the temperature at 54°C, add 120kg of cocoic acid monoisopropanolamide, stir to dissolve and mix well, then add 360kg of fatty alcohol polyoxyethylene ether glucoside (R 1 =14, m=2, n=3) and 80kg of isopropanol, stirred and dissolved evenly, then added 240kg of sodium α-alkenyl sulfonate (R 2 =13, n=1), and stir evenly to obtain an oil-resistant, anti-adsorption and low-tension foam oil displacement agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com