High-strength special steel

A high-strength and special technology, applied in the directions of stirring device, separation method, charging treatment type, etc., can solve the problems of waste of resources, comprehensive heating of raw materials, high cost, etc., and achieve the effect of improving cleaning and improving permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

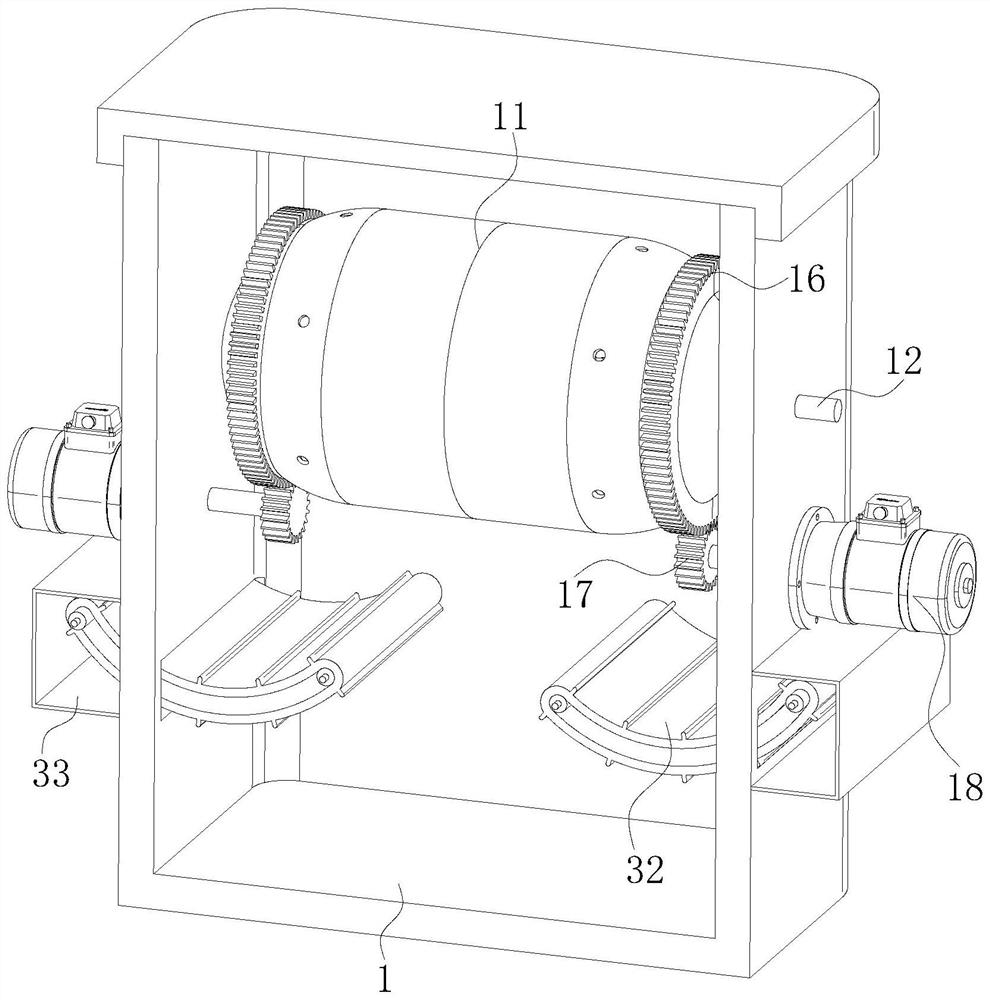

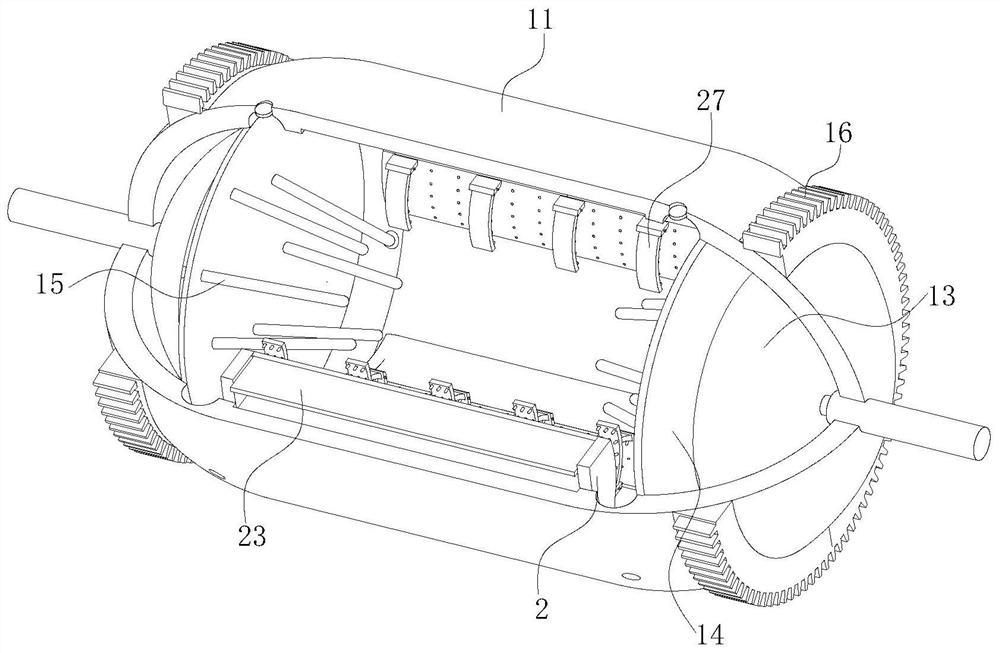

[0036] use Figure 1-Figure 7 A high-strength special steel material according to an embodiment of the present invention will be described as follows.

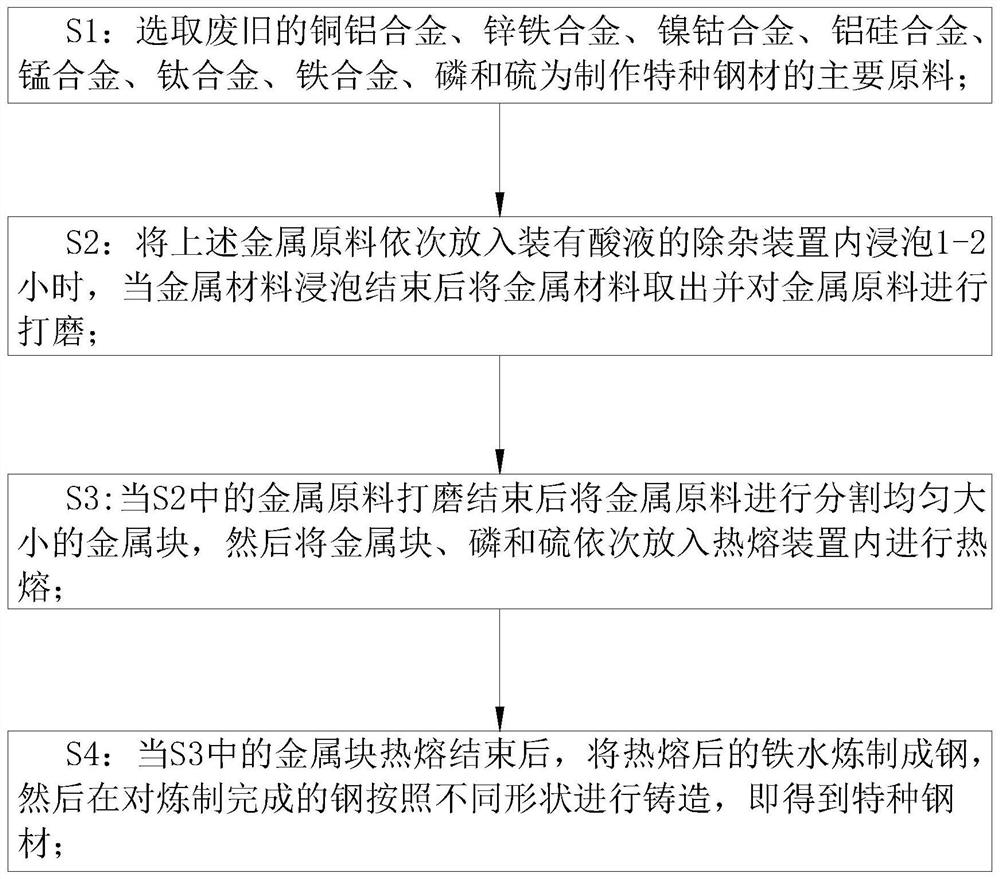

[0037] like Figure 1-Figure 7 Shown, a kind of high-strength special steel of the present invention, the manufacture method of this special steel comprises the following steps:

[0038] S1: Select waste copper-aluminum alloy, zinc-iron alloy, nickel-cobalt alloy, aluminum-silicon alloy, manganese alloy, titanium alloy, iron alloy, phosphorus and sulfur as the main raw materials for making special steel; Resources, improve the utilization value of materials;

[0039] S2: Put the above-mentioned metal raw materials into the impurity removal device equipped with acid solution and soak for 1-2 hours. After the metal material is soaked, take out the metal material and polish the metal raw material; Impurities and rust on the surface of raw materials are cleaned up, so that the quality and performance of special steel can be imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com