Method for detecting residual solvent in flupiperidinol

A technology for residual solvents and haloperidol, applied in the field of drug analysis, can solve the problems of inability to quickly detect residual solvents, lack of quality control standards, quality analysis of raw materials and control of adverse effects, etc., to achieve good durability and high accuracy , the effect of short running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

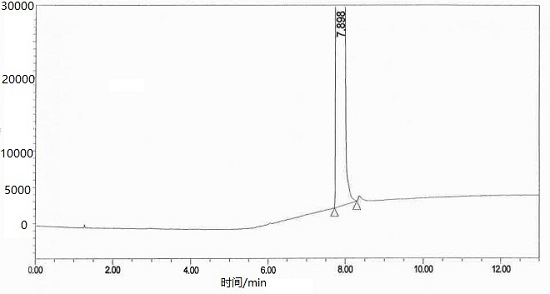

[0043] The present embodiment adopts the following detection conditions to detect need testing solution, reference substance solution and blank solvent

[0044] The chromatographic column is a DB-624 capillary column, the detector is an FID detector, the split ratio is 5:1, the heating program is initially 40°C, maintained for 5 minutes, then raised to 220°C at a speed of 60°C / min, maintained for 5 minutes, and the line The speed is 30 cm / s, the temperature of the detector is 250 °C, the injection volume is 1 μL, and the temperature of the injection port is 200 °C. Specific results such as Figure 1-Figure 6 And as shown in Table 1:

[0045] Table 1

[0046]

[0047] From the results of Example 1, it can be seen that the blank solvent does not interfere with the determination, and the minimum separation degree of methanol, ethanol, and methylene chloride in the mixed solution is 6.77, which meets the requirements and has a good effect. Other impurity peaks in the test sol...

Embodiment 2

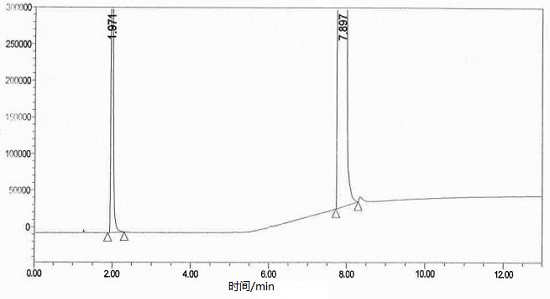

[0049] The present embodiment adopts following method, detects need testing solution, reference substance solution:

[0050] The chromatographic column is a DB-624 capillary column, the detector is an FID detector, the split ratio is 5:1, the heating program is initially 40°C, maintained for 5 minutes, then raised to 220°C at a speed of 60°C / min, maintained for 5 minutes, and the line The speed is 25 cm / s, the temperature of the detector is 250 °C, the injection volume is 1 μL, and the temperature of the injection port is 200 °C. The result is as Figure 7 , Figure 8 shown.

Embodiment 3

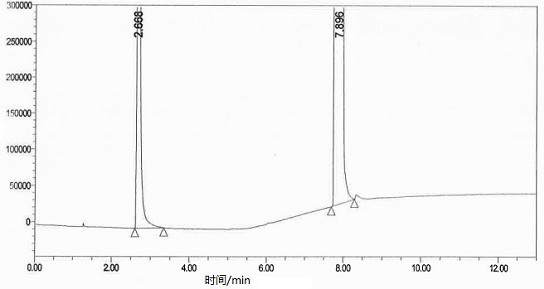

[0052] The present embodiment adopts following method, detects need testing solution, reference substance solution:

[0053] The chromatographic column is a DB-624 capillary column, the detector is an FID detector, the split ratio is 5:1, the heating program is initially 40°C, maintained for 5 minutes, then raised to 220°C at a speed of 60°C / min, maintained for 5 minutes, and the line The speed is 35 cm / s, the temperature of the detector is 250 °C, the injection volume is 1 μL, and the temperature of the injection port is 200 °C.

[0054] The result is as Figure 9 , Figure 10 shown.

[0055] Comprehensively test again by the detection condition of embodiment 1, the result of comprehensive embodiment 2, embodiment 3 is as shown in table 2 below:

[0056] Table 2

[0057]

[0058] As can be seen from the results in Table 2, the linear velocity changes within ± 5cm / s, and in the reference substance and the test solution, the solvent peak of N,N-dimethylformamide does not i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com